High-speed rail double-block type sleeper production line and production method

A double-block, production line technology, applied in the field of high-speed rail sleeper manufacturing, can solve problems such as equipment continuity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

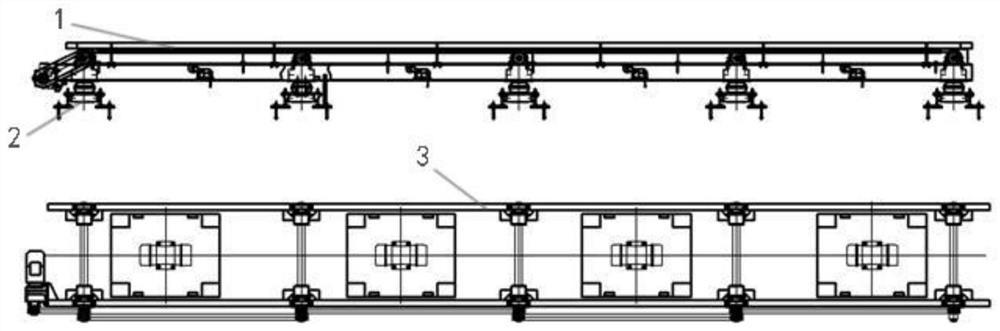

Image

Examples

Embodiment 1

[0037] Embodiment 1, the present invention is designed with high-speed rail double block type sleeper production line, comprises a plurality of stations, and each station has corresponding equipment to carry out operation, and concrete station is as follows:

[0038] 1.1 Truss reinforcement processing station:

[0039] The fully automatic truss reinforcement production line for sleepers has three functions: cold rolling unit, CNC hoop bending machine, and truss welding unit. First, the cold-rolled steel bars are formed into coils, and each steel bar is straightened and introduced into the designated position through the straightening mechanism to form steel bars. The prototype of the truss; after preliminary positioning, the chords on both sides are processed into waves to release the stress, and the wave-shaped steel bars are accurately fixed by high-pressure cylinders. While positioning, the steel bars are firmly welded at the specified position. Through a set of high-pressu...

Embodiment 2

[0101] Embodiment two, the production method step of the production line of the present invention is specifically as follows:

[0102] Step 1: The mold is conveyed by the roller table to the mold cleaning station. The model cleaning equipment is composed of a turning mechanism, a roller conveying mechanism, and a sandblasting machine. The mold conveyed by the roller conveying line is turned over 180 degrees through the turning mechanism, and placed in the Another roller conveying line; the flipping is driven by the frequency conversion deceleration motor to rotate slowly, and the mold flipped to the line body is transported to the sandblasting machine for sandblasting cleaning, and then transported to the flipping position after cleaning, waiting for flipping back.

[0103] The suction sandblasting method is adopted, that is, the compressed air flows at high speed in the spray gun to form a negative pressure to generate ejection effect, and the abrasive in the sand separator st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com