Building waste material crushing device

A crushing device and technology for construction waste, applied in grain processing, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of small waste easily splashing everywhere, environmental pollution, and affecting the work efficiency of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

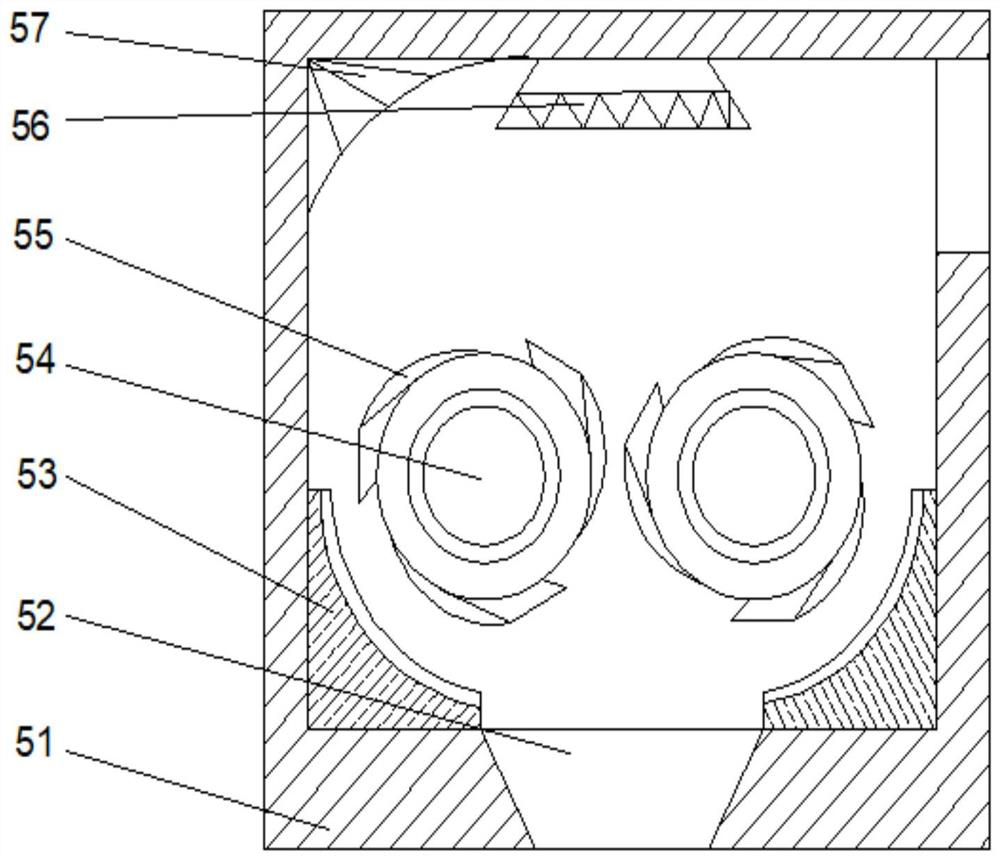

[0032] see Figure 1-2 , the present invention provides a technical solution: a construction waste crushing device, including a base 1, a motor 2 is fixedly connected to both sides of the back of the base 1, a protective cover 3 is arranged on the top of the motor 2, and an organic body 4 is fixedly connected to the top of the base 1 , The body 4 is fixedly connected with a crushing device 5, the front middle part of the crushing device 5 is provided with a feed inlet 6, and the left top middle of the crushing device 5 is fixedly connected with a controller 7.

[0033] Wherein, the crushing device 5 includes a main body 51, an adjuster 56 is arranged at the middle position of the inner cavity top of the main body 51, a baffle plate 57 is fixedly connected to the left side of the inner cavity top of the main body 51, and a transition groove is opened at the middle position of the inner cavity bottom of the main body 51. 52. The bottom of the inner cavity of the main body 51 is ...

Embodiment 2

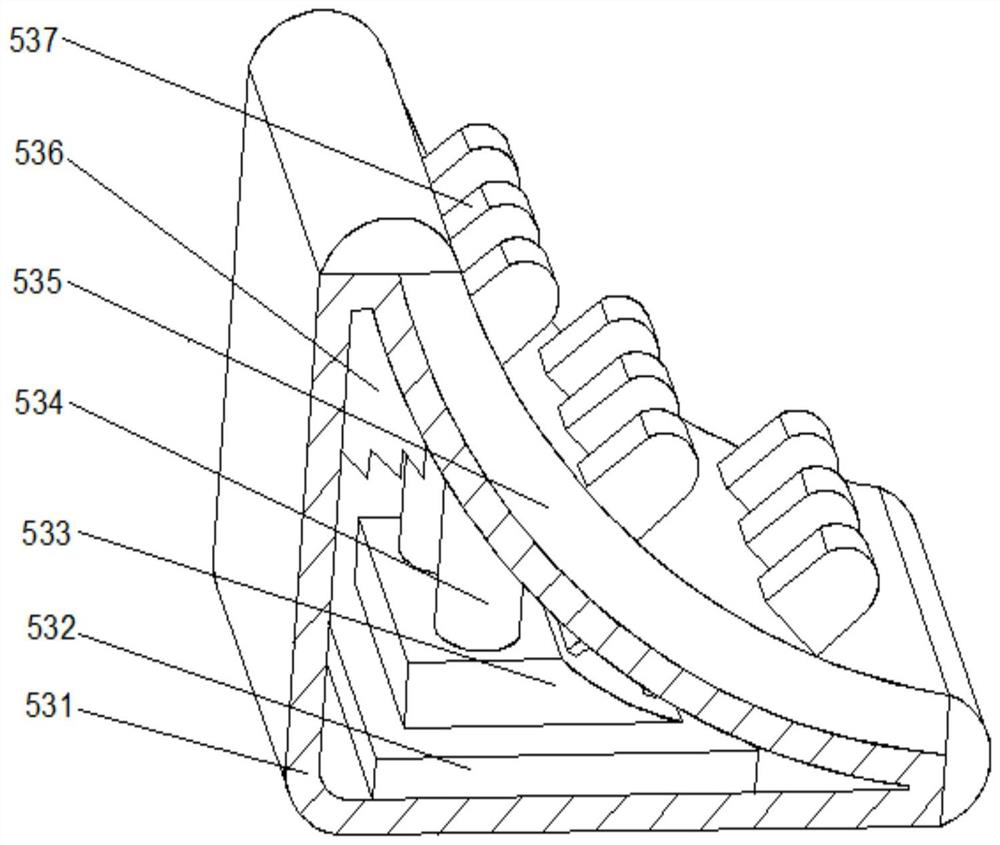

[0036] see Figure 1-3 , on the basis of Embodiment 1, the present invention provides a technical solution: the auxiliary mechanism 53 includes an auxiliary frame 531, the middle position of the inner cavity bottom of the auxiliary frame 531 is fixedly connected with a bottom plate 532, and the bottom of the bottom plate 532 is fixedly connected with a support frame 533 , the top middle position of the support frame 533 is fixedly connected with an auxiliary block 534, the top of the inner cavity of the auxiliary frame 531 is fixedly connected with a limit block 536, the right outer wall of the auxiliary frame 531 is fixedly connected with an auxiliary plate 535, and the surface of the auxiliary plate 535 is provided with The linkage mechanism 537 , the bottom of the linkage mechanism 537 passes through the auxiliary board 535 and extends to the inside of the auxiliary board 535 .

[0037] When in use, when the crushed waste falls on the auxiliary mechanism 53, the interior of t...

Embodiment 3

[0039] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the linkage mechanism 537 includes a frame d1, the top of the frame d1 is fixedly connected with a linkage ring d6, and the inside of the linkage ring d6 is provided with an elastic ball d7, The bottom of the inner wall on both sides of the frame d1 is provided with a linkage block d2, the side of the linkage block d2 away from the frame d1 is fixedly connected with an elastic rod d4, the middle part of the elastic rod d4 is fixedly connected with a fixed strip d3, and the top of the elastic rod d4 is provided with a left Institution d5.

[0040] Wherein, the left mechanism d5 includes a contact block d51, the bottom of both sides of the contact block d51 is fixedly connected with the bearing plate d52, the top of the bearing plate d52 is fixedly connected with the receiving plate d57, and the top side of the bearing plate d52 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com