a soybean milk machine

A soymilk machine and machine head technology, which is applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of reduced fun of soymilk drinks, hidden safety hazards, and easy pollution of the desktop, etc., and achieves convenient installation, compact installation structure, fine lifting degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

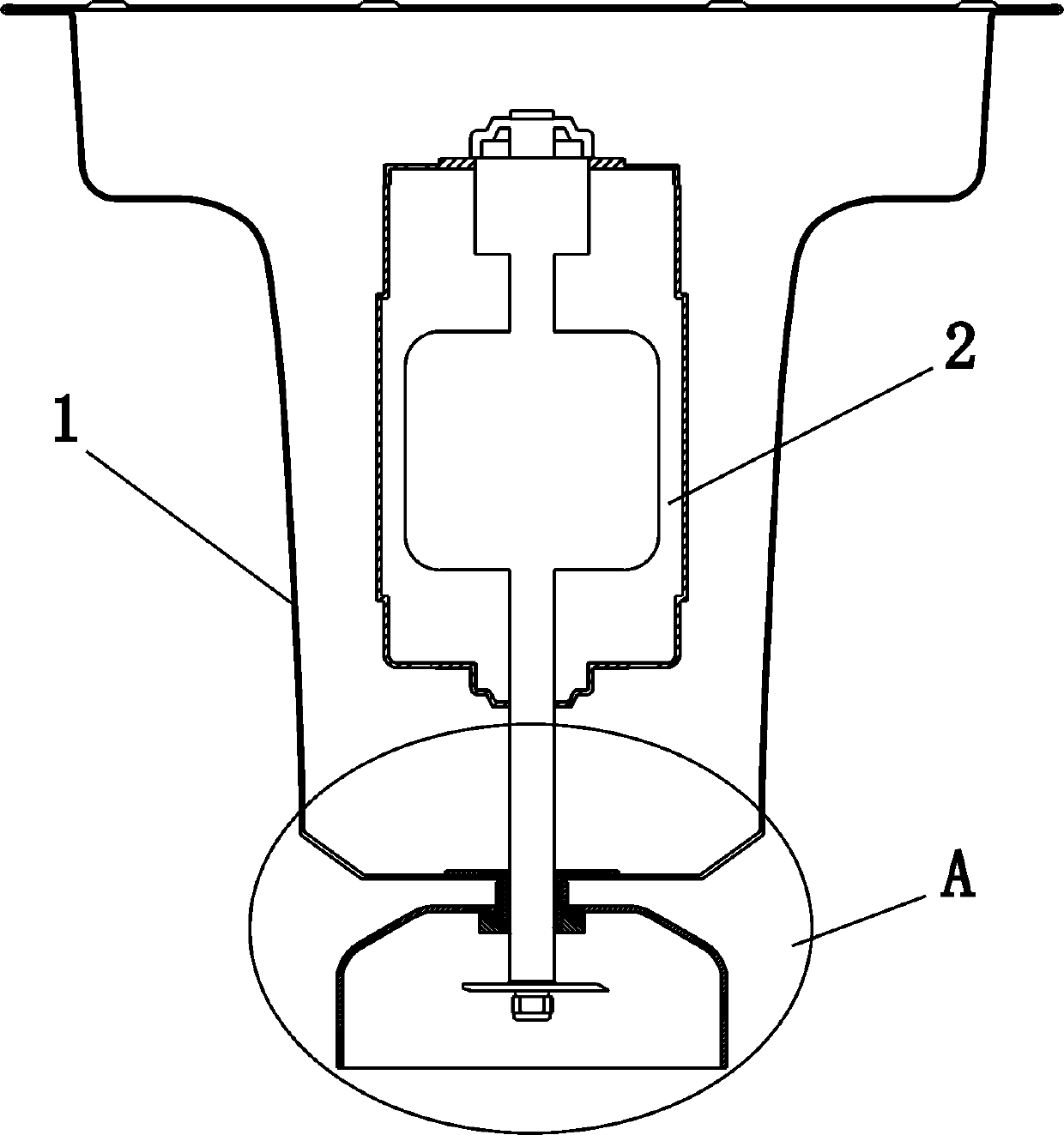

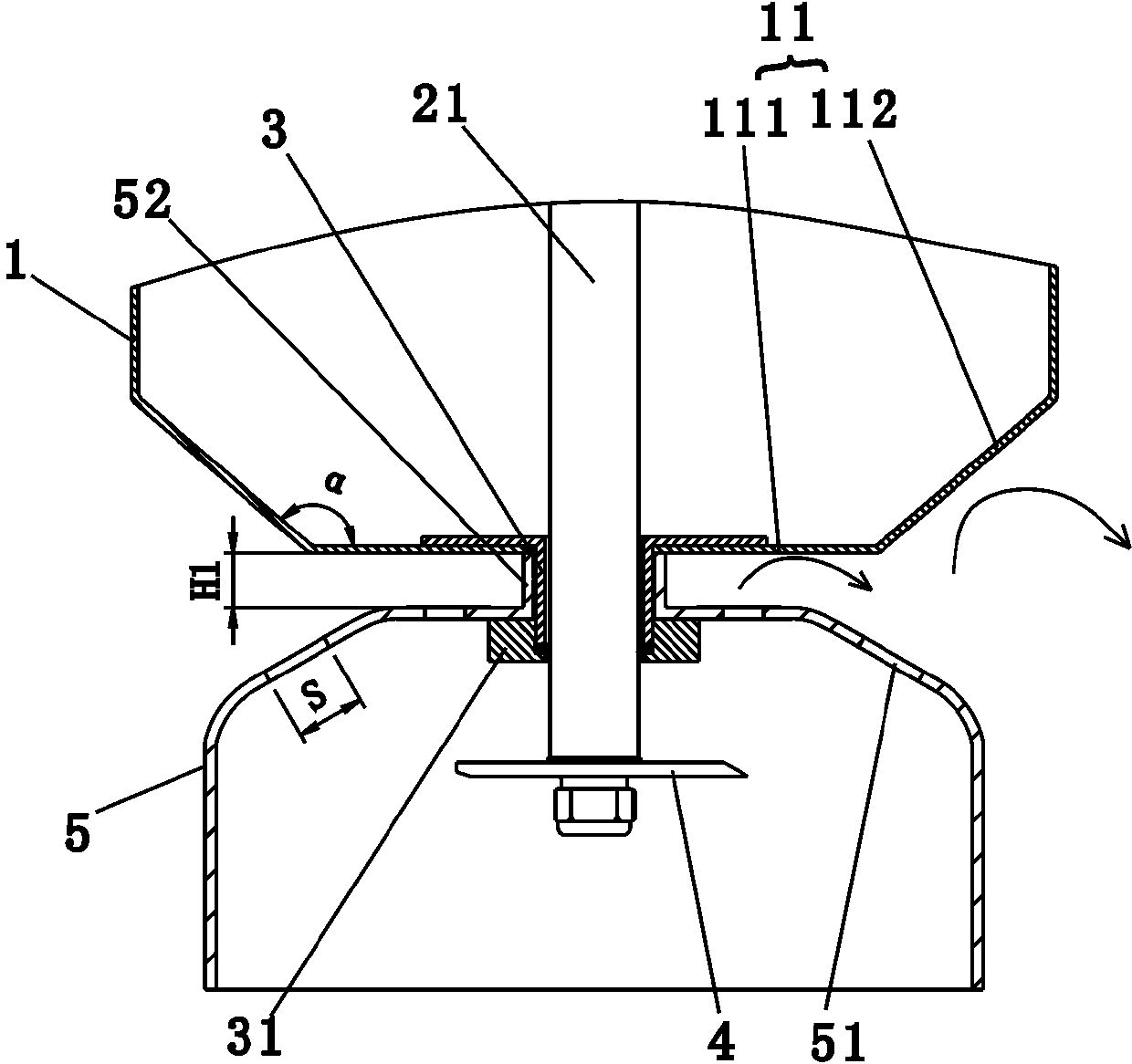

[0022] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A soybean milk machine, comprising a machine head and a cup body (not shown in the figure), the machine head includes a machine head upper cover (not shown in the figure) and a machine head lower cover 1, the machine head lower cover 1 A motor 2 is provided, the bottom of the machine head lower cover 1 is provided with a connecting body 3 protruding downward, the end of the motor shaft 21 is equipped with a pulverizing blade 4, and the bottom of the connecting body 3 is provided with a shroud 5, so The pulverizing blade 4 is located in the shroud 5, and the shredder 5 is provided with a diversion hole 51 above the shredding blade 4, and the motor shaft 21 drives the pulverizing blade 4 to rotate and pump the liquid flow to be guided through the shroud 5. The hole 51 sprays to the outside of the guide cover 5, and the bottom of the lower cover 1 of the...

Embodiment 2

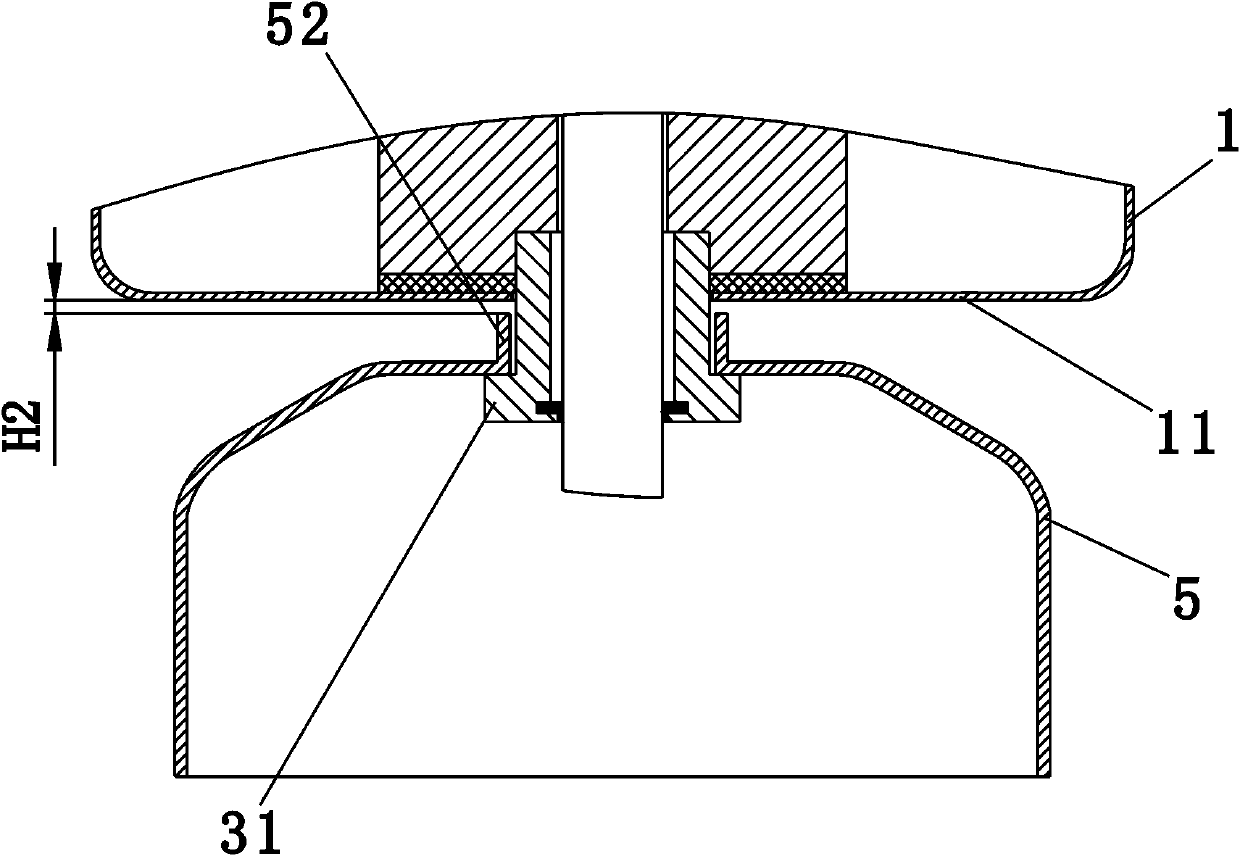

[0029] Such as image 3 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference from Embodiment 1 is that in this embodiment, the spoiler surface 11 is the bottom outer plane of the lower head cover 1, and the air deflector 5 is movably installed between the lower head cover 1 and the convex ring 31. and the distance between the top of the sleeve part 52 and the bottom outer plane of the lower nose cover is H2. The movable installation of the wind deflector 5 is to guide the wind deflector to be positioned between the lower nose cover 1 and the convex ring 31. Circumferential rotation or axial movement.

[0030] In this embodiment, since the guide cover can rotate in the circumferential direction, the sleeve part and the connecting cylinder are in clearance fit, and during the pulping process, the movement of the guide cover will change the original trajectory of the liquid flow, thereby increasing The effect of turbulent flo...

Embodiment 3

[0032] Such as Figure 4 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and the above-mentioned embodiments is that in this embodiment, the connecting body 3 is a connecting bracket, the top of the connecting bracket is detachably connected to the lower cover 1 of the machine head, and the bottom is connected to the air guide cover 5 Shaped together.

[0033] It should be noted that, in this embodiment, the connecting bracket and the nozzle cover are integrally formed, and the connecting bracket and the lower cover of the machine head are detachable and fixed, which is beneficial to the cleaning of the nozzle cover and the machine head. Of course, the connecting bracket can also be integrated with the lower cover of the machine head, and the shroud and the connecting bracket are detachable and fixed structures. For this embodiment, the connecting bracket can be fixed on the bottom outer plane of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com