A high-efficiency extraction process of antler discs

An extraction process and technology of antler trays, which are applied in solvent extraction, solid solvent extraction, and cleaning methods using liquids, etc., can solve the problems affecting the effective utilization rate of antler trays, waste, and low extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

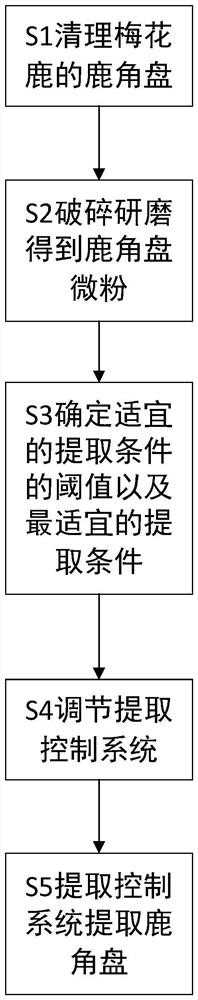

[0047] Such as figure 1 Shown, a kind of high-efficiency extraction process of antler disc, comprises the following steps:

[0048] S1 Select the antler discs of sika deer, soak them in clean water for 3 hours, rinse the surface of the antler discs with running water after ultrasonic vibration, and clean them with a brush to obtain the cleaned antler discs;

[0049] S2 dried the antler dish after cleaning in an oven at 65°C, such as image 3 As shown in Figure A in the middle, the dried antler discs are broken into image 3 4cm shown in Figure B 2 The small pieces of the traditional Chinese medicine were crushed quantitatively according to the 20g sample each time, and sieved with a 200-mesh sieve to obtain the following: image 3 For the antler disc particles shown in Figure C in the middle, the obtained antler disc particles are repeatedly ground by a micronizer to obtain the following: image 3 The antler disc micropowder shown in Figure D;

[0050] S3 Use double-disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com