Decoloring hydrolyzing equipment applied to preparation of seaweed dietary fibers

A technology of seaweed dietary fiber and hydrolysis equipment, applied in food science and other directions, can solve problems such as affecting the preparation process and increasing the difficulty of staff work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

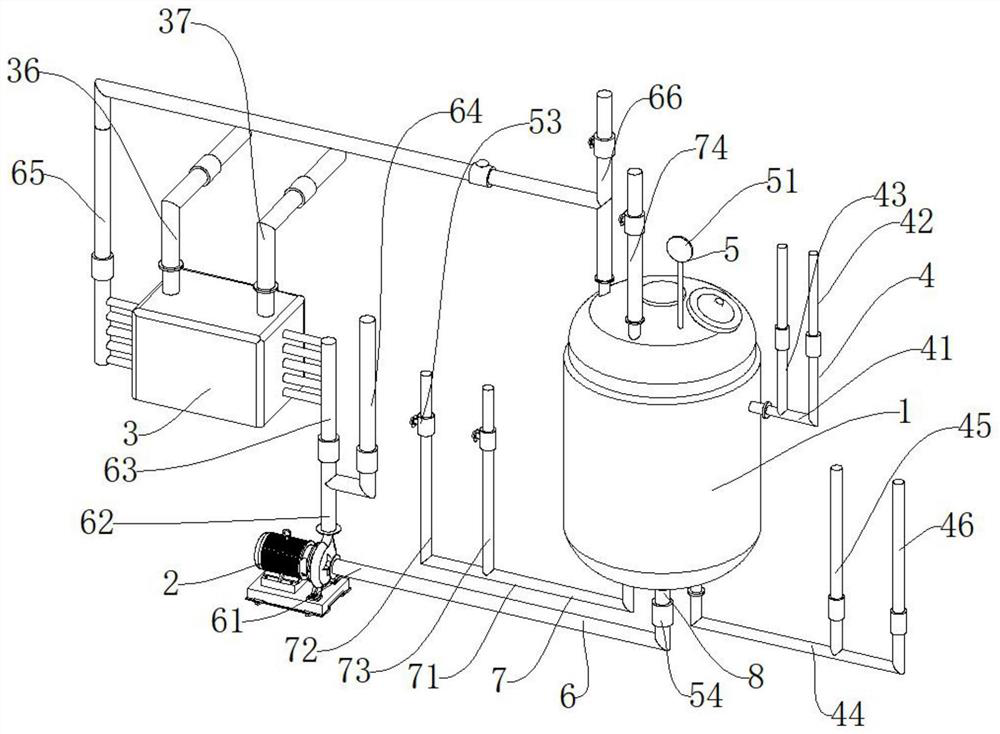

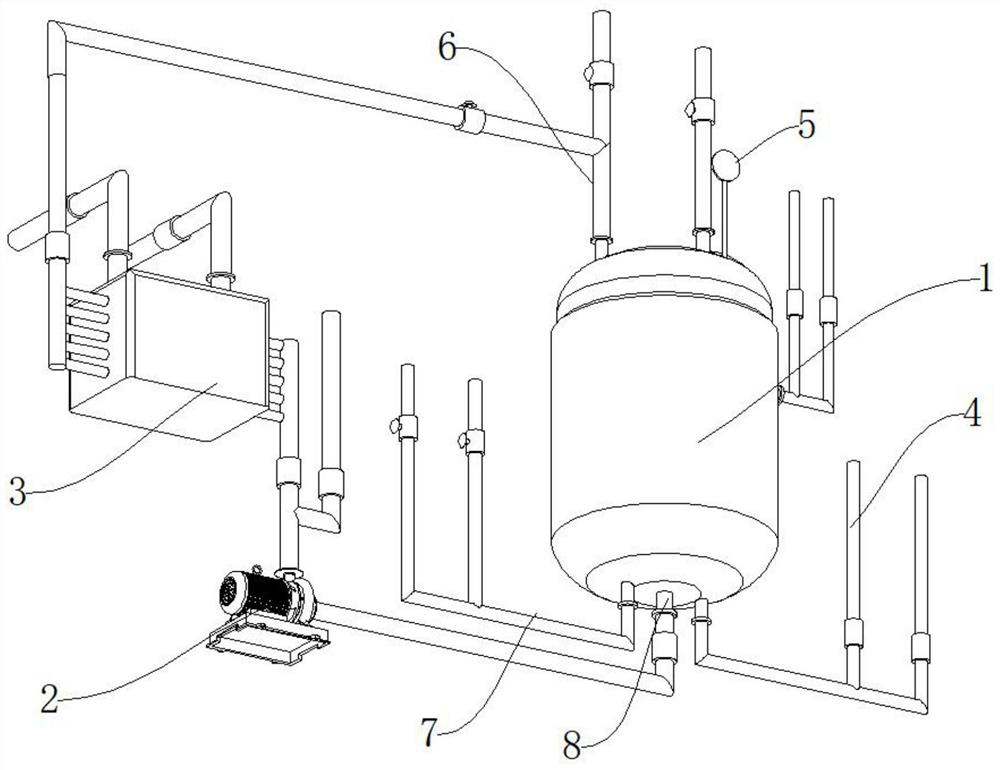

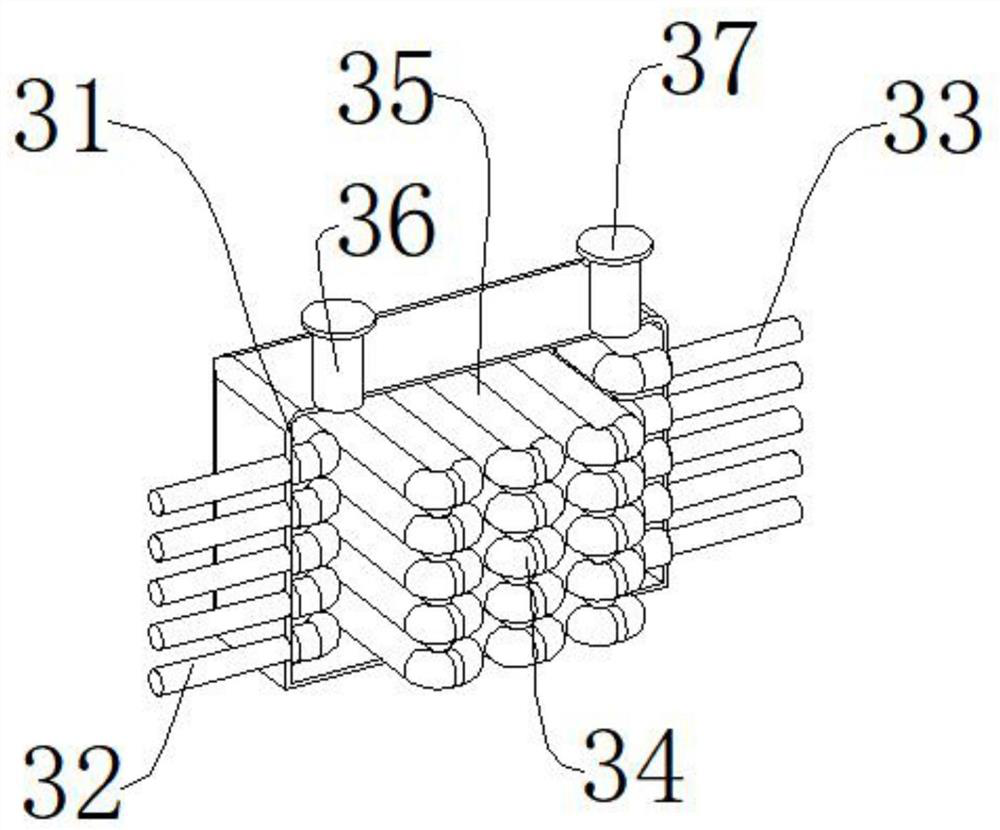

[0042] Such as Figure 1-Figure 6As shown, a decolorization and hydrolysis equipment used in the preparation of seaweed dietary fiber includes a decolorization and hydrolysis tank 1, a delivery pump 2, and a heat exchange mechanism 3. One side of the decolorization and hydrolysis tank 1 is connected to a temperature control mechanism 4, and the upper end of the decolorization and hydrolysis tank 1 is connected to a conveying Mechanism 6, one end of the conveying mechanism 6 is provided with a detection mechanism 5, the lower end of the decolorization and hydrolysis tank 1 is connected to the auxiliary material mechanism 7, the conveying mechanism 6, the auxiliary material mechanism 7 and the decolorization and hydrolysis tank 1 are all connected through a joint 8, and the temperature control mechanism 4 includes return water Main pipe 41, chilled water return pipe 42, hot water return pipe 43, water inlet main pipe 44, chilled water return pipe 42 and hot water return pipe 43 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com