Inverter control method, switch tube drive circuit, controller and inverter

A technology for driving circuits and control methods, applied in control/regulating systems, instruments, electrical components, etc., can solve the problems of reduced inverter operating efficiency, increased voltage stress and loss of switching tubes, slow turn-off speed, etc. Current rate of change, reduced turn-off loss, and effect of reduced reverse stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

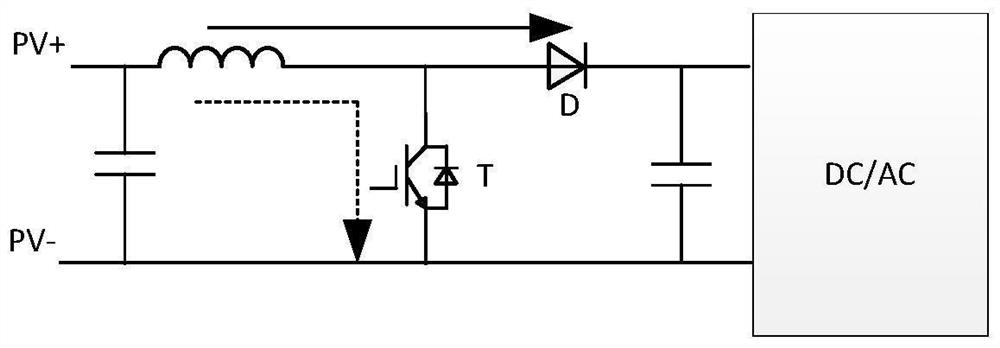

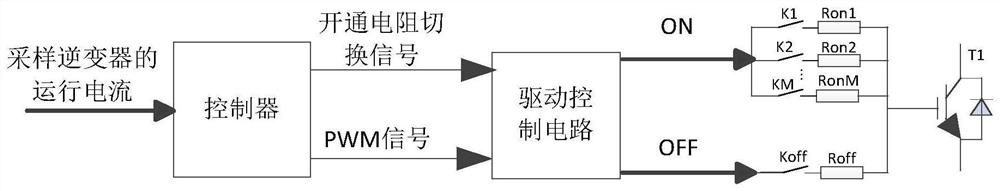

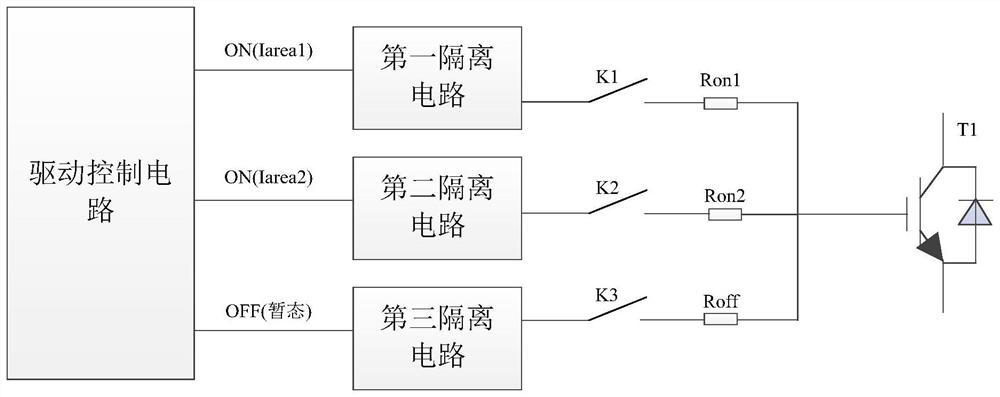

[0060] See figure 1 , which shows the topology of a two-level boosted inverter, such as figure 1 As shown, the function of the diode D is freewheeling. Specifically, when the switch tube T is turned off, the diode D freewheels. When the switch tube T is turned on, the diode D commutates to the switch tube T, and the diode D is turned off. In the process of studying the present invention, it is found that in the process of commutating the diode to the switch tube, due to the short turn-on time of the switch tube T, the problem that the current change rate is too large during the turn-off process of the diode D is likely to occur. The stress will be superimposed on the switch tube T, resulting in an increase in the stress and loss of the switch tube. Moreover, when the operating current of the inverter is small, the stress of the diode exceeds the standard more seriously.

[0061] Therefore, in order to solve the technical problem that the diode stress exceeds the standard in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com