High-precision induction linear displacement sensor

A linear displacement and sensor technology, applied in the field of sensors, can solve the problems that magnetic displacement sensors cannot realize linear translation measurement and reduce measurement accuracy, and achieve good dustproof and anticorrosion performance, high measurement accuracy and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

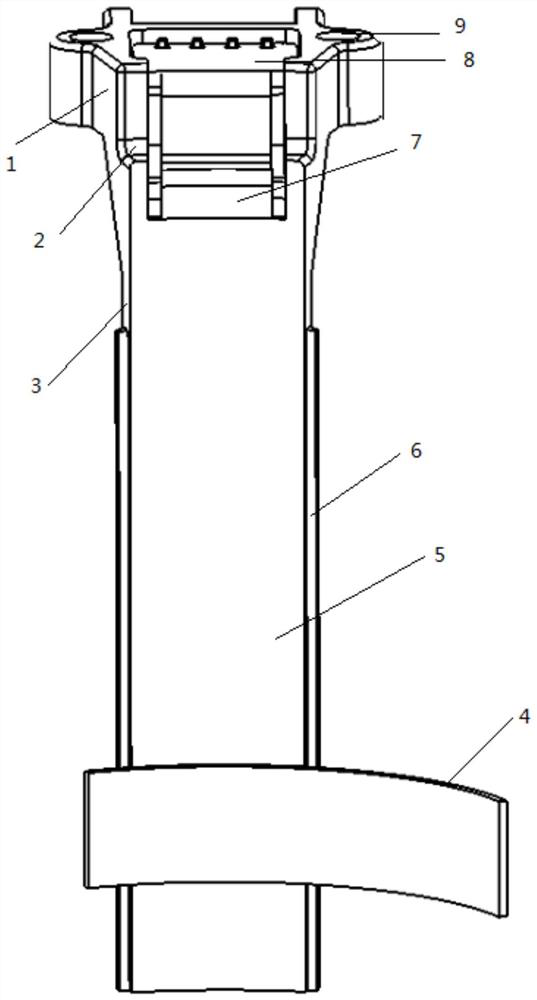

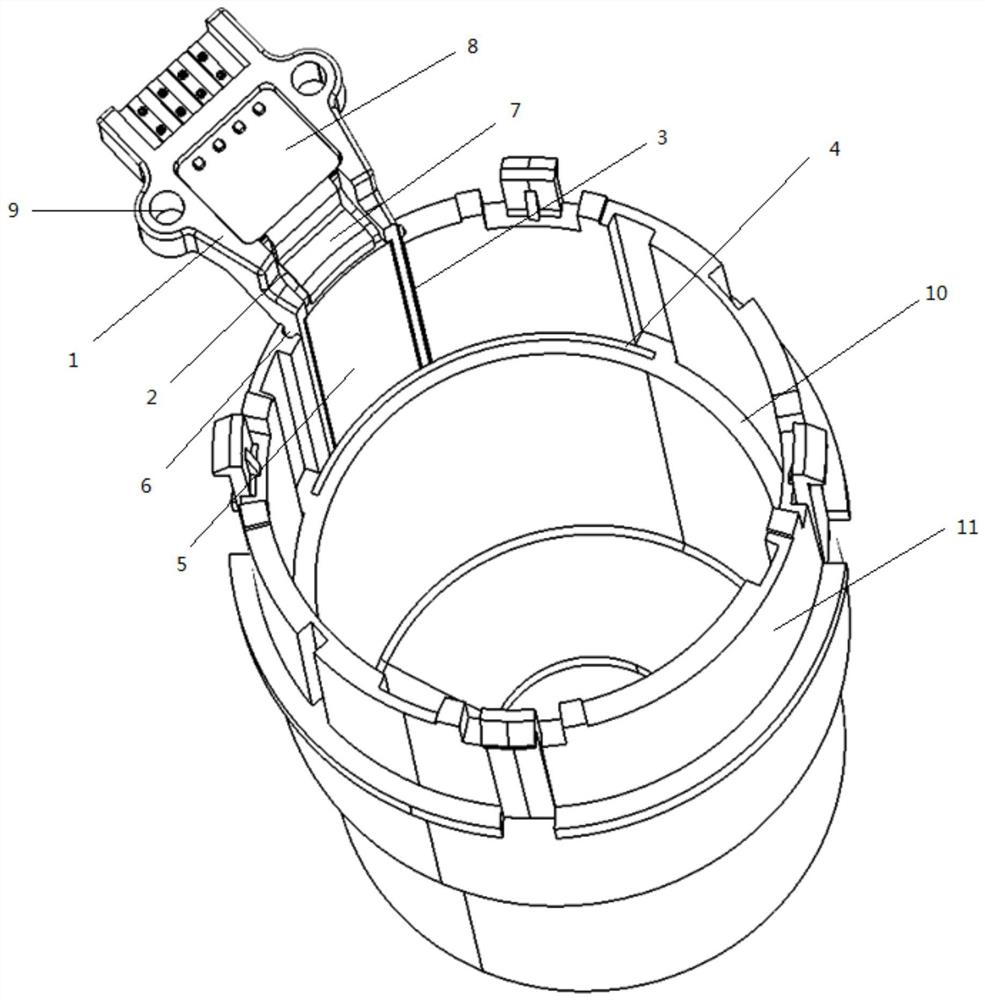

[0020] A high-precision inductive linear displacement sensor, which includes an outer shell, a chip 8, a measuring body, and an inductive sheet 4, the inductive sheet is stamped from a metal material, the outer shell is an L-shaped structure, and includes an integrally formed chip installation Part 1 and measuring body mounting part 3, the chip is clamped on the chip mounting part, the measuring body is a flexible circuit board 7, and the flexible circuit board and the measuring body mounting part are integrated by low-pressure injection molding and are integrated with the measuring body of the chip. interface connection.

[0021] Optimized, the induction piece, the measuring body mounting part and the flexible circuit board are all arc-shaped thin-walled structures, which can realize accurate measurement of linear translation between two thin-walled cylinders with an interval of <1mm. The induction piece is fixedly installed on the The outer wall of a cylinder moves linearly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com