Vehicle exhaust particulate filtering and regenerating device and method and vehicle

A regeneration device and particle technology, applied in the direction of exhaust device, electric control of exhaust treatment device, exhaust treatment, etc., can solve problems such as flameout and engine damage, and achieve the effect of avoiding engine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

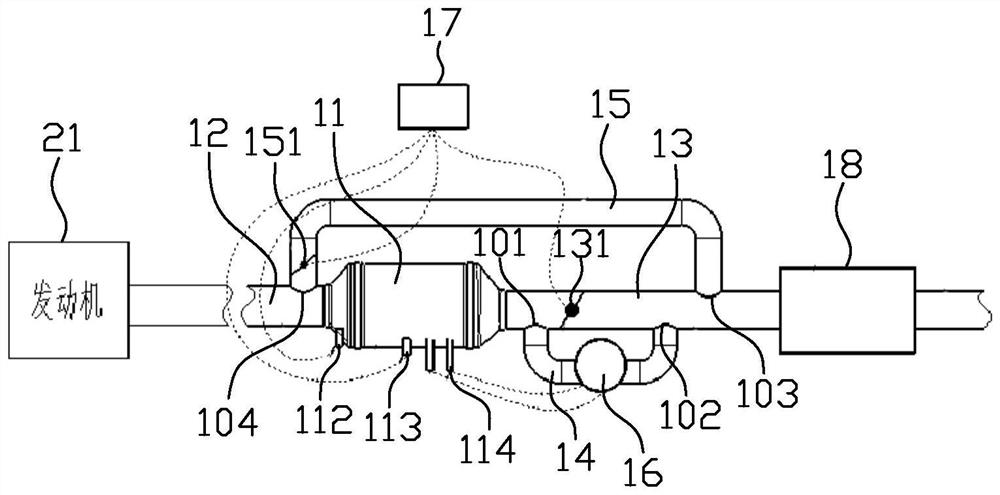

[0034]figure 1It is a schematic diagram of a vehicle exhaust particle regeneration device according to the first embodiment of the present invention, such asfigure 1As shown, the vehicle exhaust particles regenerated the regeneration apparatus includes a particulate replenishing collector 11, a intake pipe 12, a first exhaust pipe 13, a second exhaust pipe 14, a third exhaust pipe 15, a generator 16, and a control system 17. An heating network (not shown) is provided in the particle push collector 11, and one end of the intake pipe 12 is connected to the air source, and the other end of the intake pipe 12 is connected to the intake port of the particle replenrel 11, the first exhaust pipe One end of 13 is connected to the air outlet of the particle push collector 11, and the first exhaust valve 131 is provided in the first exhaust pipe 13, and the first exhaust pipe 13 is sequentially provided in the longitudinal direction. The second mounting hole 102 and the third mounting hole 10...

no. 2 example

[0051]The invention also relates to a vehicle exhaust particle regenerative method, the method utilizing the above-described vehicle exhaust particles to regenerate the regeneration device, including:

[0052]S1, when detecting that the intake port pressure of the particle pose 11 is smaller than the PL, the first exhaust valve 131 is controlled, and the second exhaust valve 151 is controlled;

[0053]S2, when the air intake pressure of the particle pose collector 11 is larger than Pm, the first exhaust valve 131 and the second exhaust valve 151 are controlled, and the air flow passes through the second exhaust pipe 14 to generate electric power generation, heating Net heating the particulate matter supplied by the thermal burning particles 11;

[0054]Among them, the PL is the air inlet pressure of the newly mounted particle replenishment collector 11; the PM is the air inlet pressure when the particle replenishing collector 11 reaches the maximum particle capture capacity.

[0055]Further, th...

no. 3 example

[0075]The invention also relates to a vehicle including the above-described vehicle exhaust particles to regenerate the regeneration device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com