Steel sleeve construction process and assembly method

A technology of construction technology and assembly method, which is applied in shaft lining, shaft equipment, earthwork drilling and mining, etc., and can solve potential safety hazards, formation strength and permeability that cannot meet safety indicators, and poor sealing between steel sleeves and portal steel rings And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

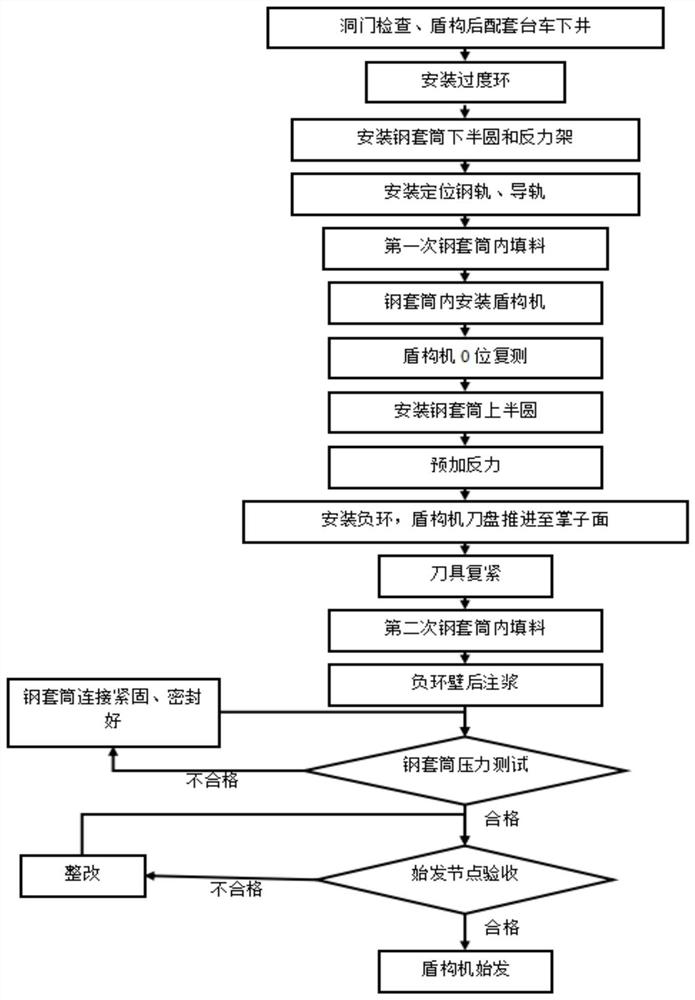

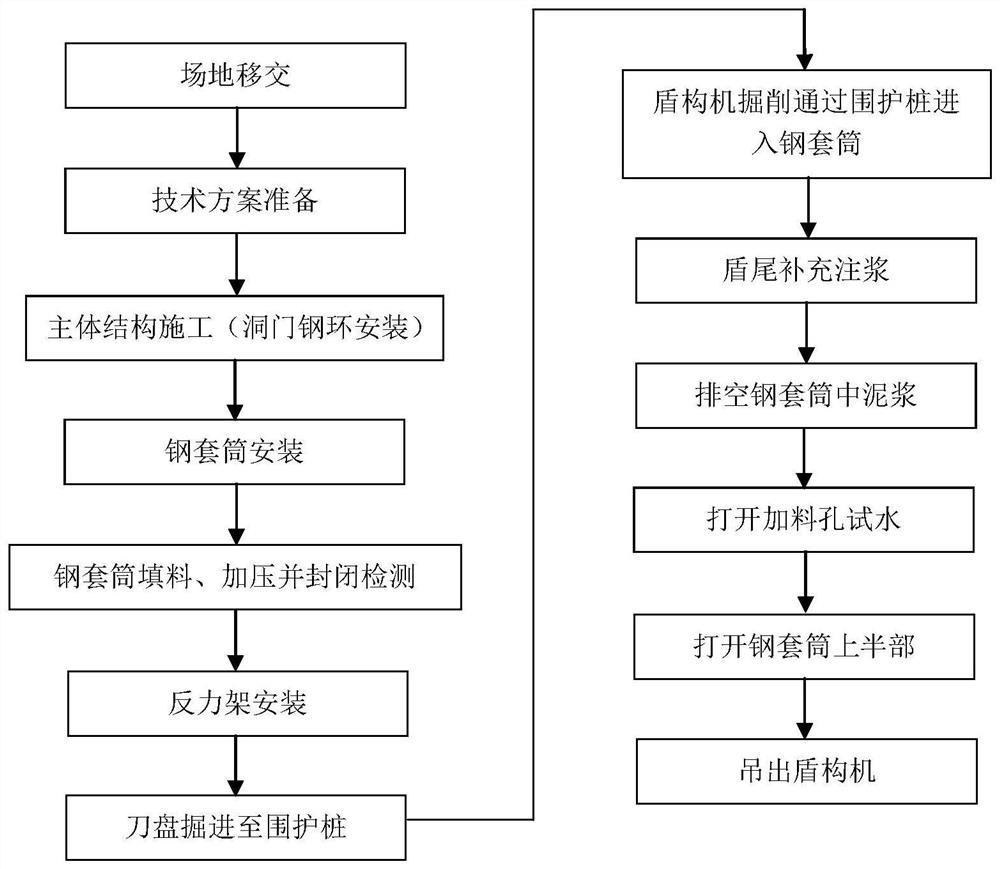

[0031] Such as Figure 1-3 Shown is the steel sleeve construction process and assembly method of the present invention, including the steel sleeve initiation construction process and the steel sleeve reception construction process;

[0032] Such as figure 1 As shown, the steel sleeve originating construction process includes the following technological process:

[0033] Inspection of the hole door and the supporting trolley going down after the shield; installation of the transition ring; installation of the steel sleeve lower circle and reaction frame; installation of positioning rails and guide rails; the first filling of the steel sleeve; installation of the shield machine in the steel sleeve ;Retest at position 0 of the shield machine; install the upper semicircle of the steel sleeve; Grouting after ring wall; steel sleeve pressure test, if unqualified, fasten and seal the steel sleeve, if qualified, start node acceptance, if unqualified, carry out rectification, if qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com