A side span cast-in-place section less excavation structure and construction method

A side-span, cast-in-place technology, used in earthmoving machines/shovels, buildings, bridges, etc., can solve the problems of large excavation surface, large amount of engineering, and damage to the original mountain, so as to reduce the construction period and resources. Wasteful, easy to replace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

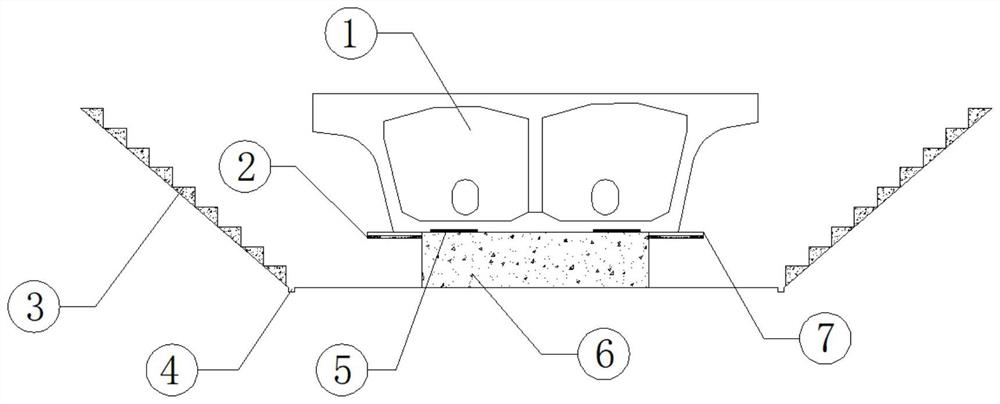

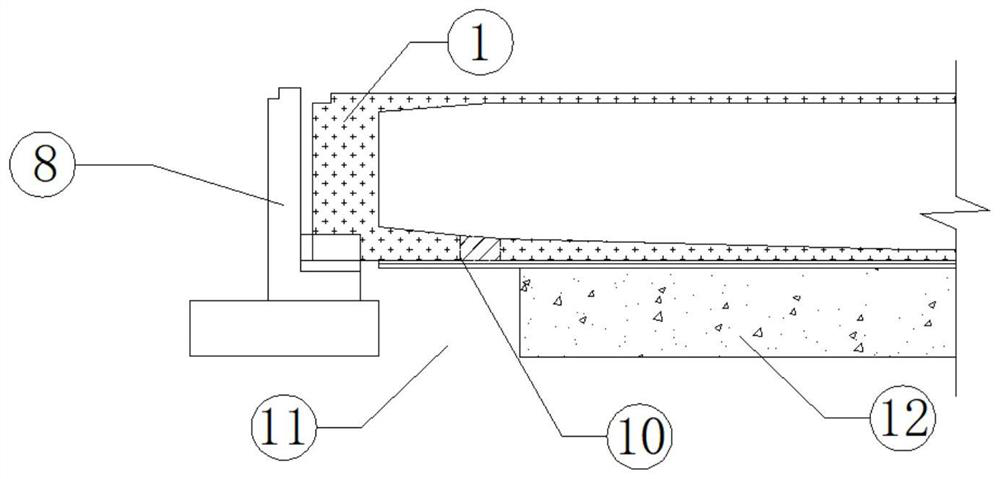

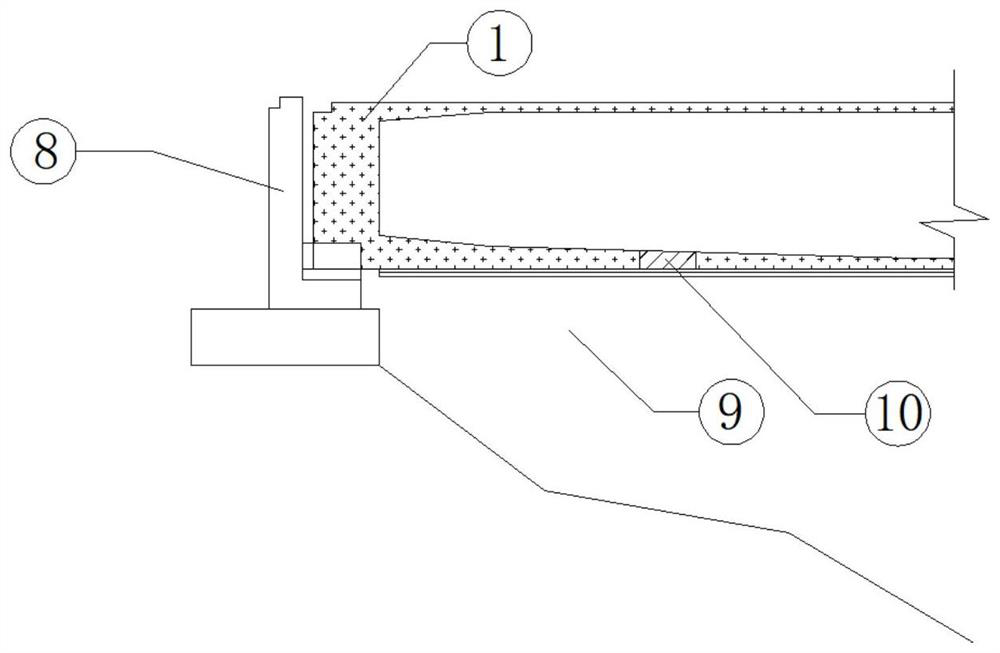

[0023] The cast-in-place section of the side span is less excavated structure, including box girder 1, concrete cushion 2, slope upper and lower steps 3, abutment 6, sand cushion 7, side span abutment 8 and manhole 10 at the bottom of the box girder; The upper part of the bridge abutment 6 is provided with a box girder 1, the bottom form of the unexcavated slope body at the bottom of the box girder 1 is sequentially laid with a concrete cushion 2 and a sand cushion 7, and a box girder is provided at the bottom of the box girder 1 near the side span abutment 8 The bottom manhole 10, and the bottom manhole 10 of the box girder is located above the excavation channel 11, and one side of the excavation channel 11 is reserved for the unexcavated surface 12; the two sides of the box girder 1 are excavated with side slopes, and the side slopes are provided with edges Slope up and down steps 3.

[0024] As a preferred embodiment, a support 5 is provided between the bridge platform 6 a...

Embodiment 2

[0030] The construction method of the side span cast-in-place section with less excavation structure comprises the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com