Elevator for construction elevator shaft and construction scheme

A technology for construction elevators and elevators, which is applied in the field of elevators, and can solve problems such as frequent loosening or breaking, elevator collapse accidents, and lack of protective measures, so as to reduce the possibility of accidents, improve safety guarantees, and solve safety protection problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

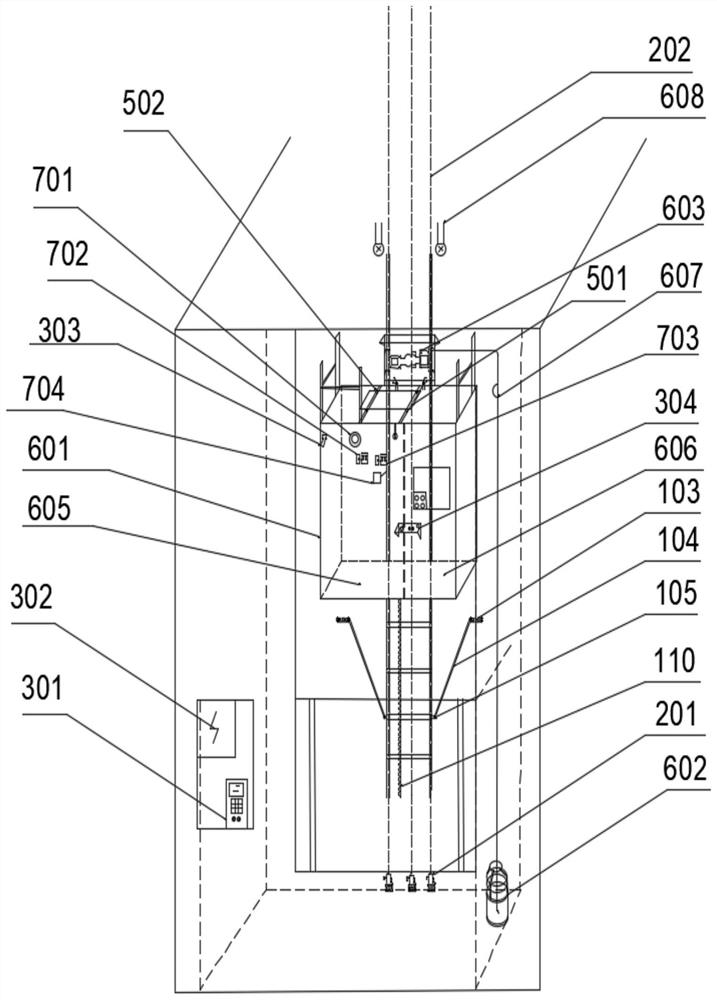

[0033] Such as Figure 1-7 As shown, the present invention is an elevator used for construction of an elevator shaft, including a wall guide rail frame 1, a vertical monitoring device 2, an intelligent door opening device 3, an emergency anti-drop device 4, a guide rail mounting frame 5, a cage running device 6 and a safety device 7;

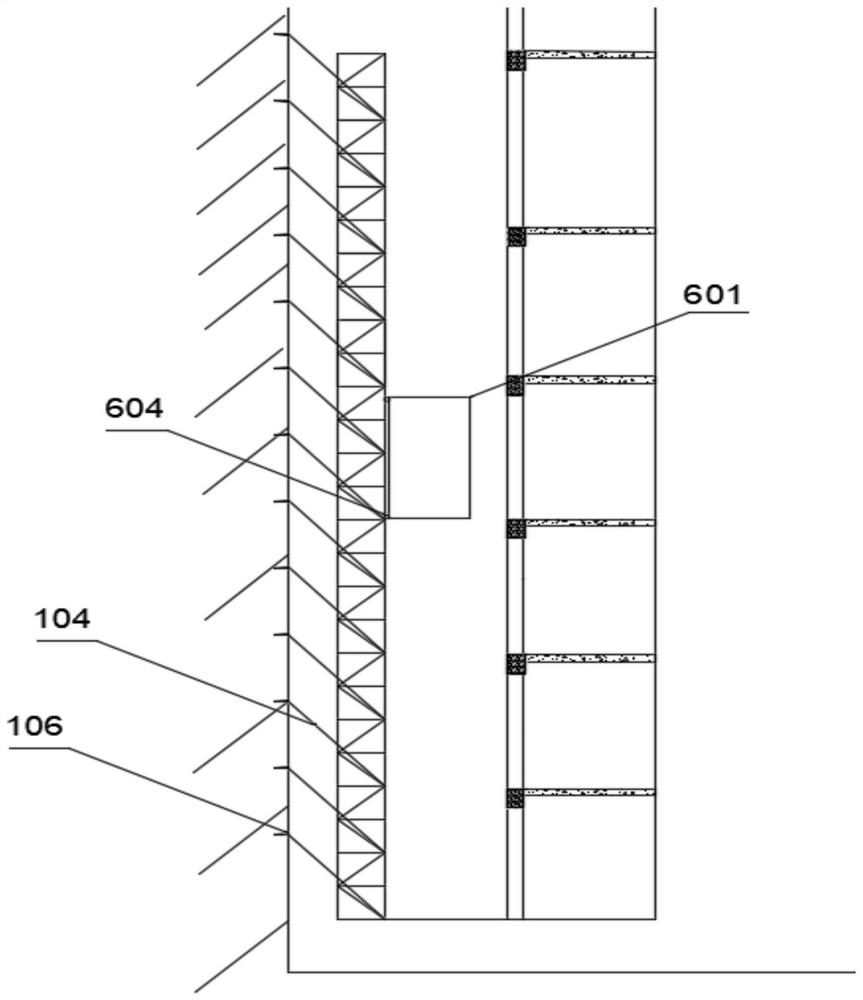

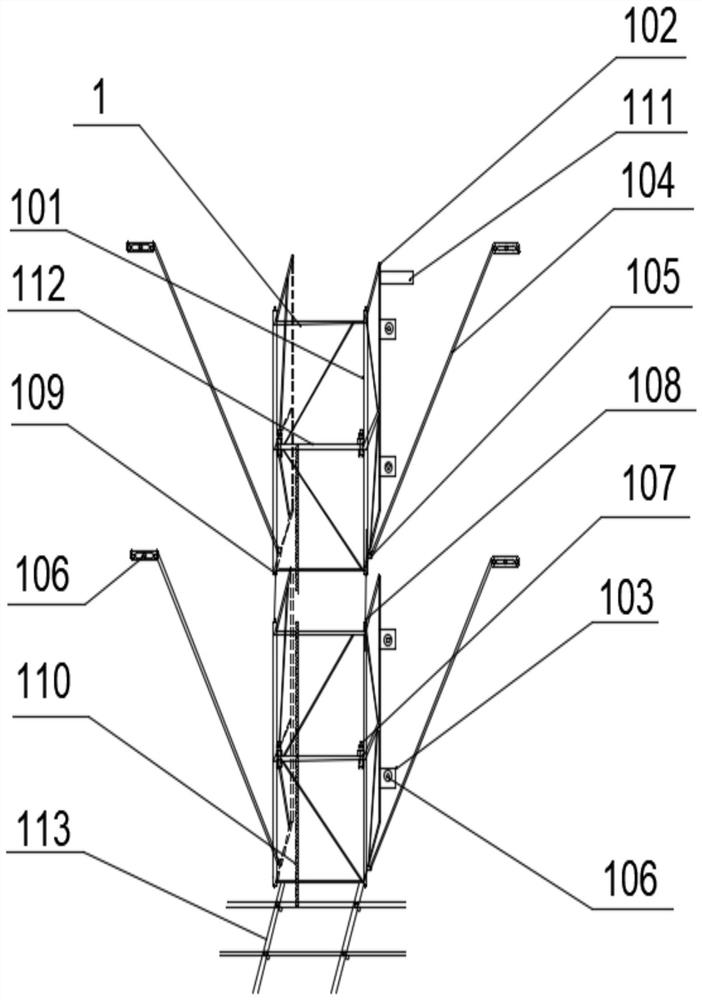

[0034] The guide rail frame attached to the wall 1 includes a cylindrical guide rail 101, a wall frame body 102, a fixed ear plate 103, a diagonal rod 104, a diagonal rod connecting sleeve 105, a fixed bolt 106, a high-strength bolt 107, a rod protruding head 108, and a rod groove 109 , transmission rack 110, height limit baffle 111, limit frame body 112, base 113, wall guide rail frame 1 is fixed on the concrete wall in the construction elevator shaft, and wall guide rail frame 1 has a cylindrical column on the front side The guide rail 101 and the side facing away from the wall frame body 102 with a square tube shape are fixed against the con...

Embodiment 2

[0037] The elevator used for the construction of the elevator shaft, including the guide rail frame attached to the wall 1, the vertical monitoring device 2, the intelligent door opening device 3, the emergency anti-drop device 4, the guide rail mounting frame 5, the cage running device 6 and the safety device 7;

[0038] The guide rail frame attached to the wall 1 includes a cylindrical guide rail 101, a wall frame body 102, a fixed ear plate 103, a diagonal rod 104, a diagonal rod connecting sleeve 105, a fixed bolt 106, a high-strength bolt 107, a rod protruding head 108, and a rod groove 109 , transmission rack 110, height limit baffle 111, limit frame body 112, base 113, wall guide rail frame 1 is fixed on the concrete wall in the construction elevator shaft, and wall guide rail frame 1 has a cylindrical column on the front side The guide rail 101 and the side facing away from the wall frame body 102 with a square tube shape are fixed against the concrete wall body, and fo...

Embodiment 3

[0042] The elevator used for the construction of the elevator shaft and the construction plan, the elevator used for the construction of the elevator shaft, including the guide rail frame attached to the wall 1, the vertical monitoring device 2, the intelligent door opening device 3, the emergency anti-drop device 4, the guide rail mounting frame 5, and the hanging cage Operating device 6 and safety device 7;

[0043] The guide rail frame attached to the wall 1 includes a cylindrical guide rail 101, a wall frame body 102, a fixed ear plate 103, a diagonal rod 104, a diagonal rod connecting sleeve 105, a fixed bolt 106, a high-strength bolt 107, a rod protruding head 108, and a rod groove 109 , transmission rack 110, height limit baffle 111, limit frame body 112, base 113, wall guide rail frame 1 is fixed on the concrete wall in the construction elevator shaft, and wall guide rail frame 1 has a cylindrical column on the front side The guide rail 101 and the side facing away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com