Environment-friendly gravel aggregate loading device and using method thereof

A kind of aggregate and environmental protection technology, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of low loading efficiency pollution, local dust pollution, material spillage, etc., achieve a smooth and uniform loading effect, and eliminate dust Pollution, effect of small falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

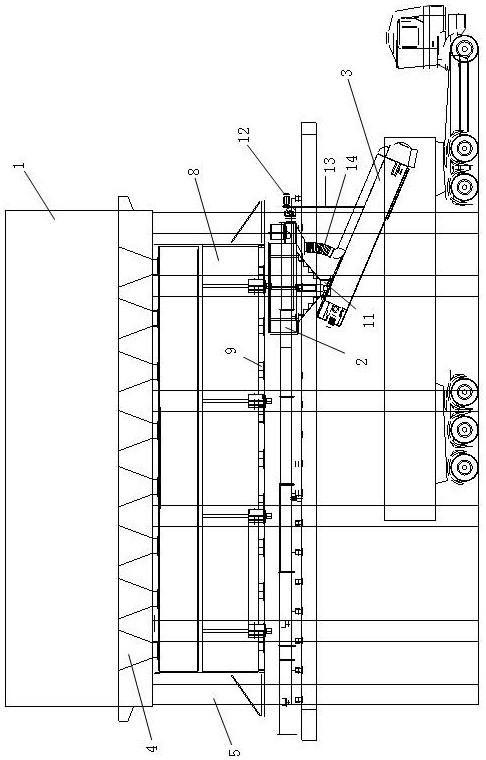

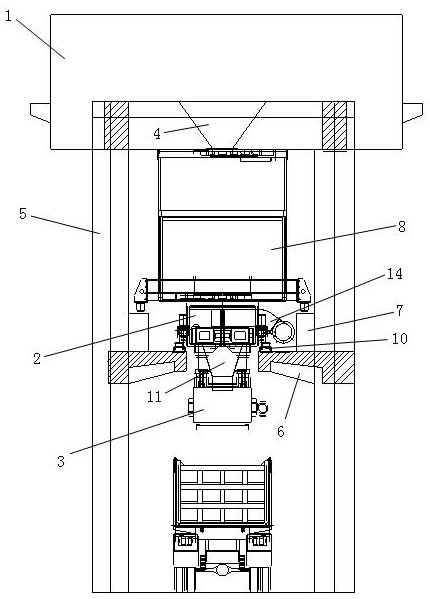

[0023] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0024] like figure 1 and figure 2 As shown, an environmental protection loading device for sand and gravel aggregates includes a material warehouse 1, a weighing bin 8, a moving hopper 2 and a conveyor 3. A discharge pipe 4 is provided at the bottom of the material warehouse 1, and a discharge pipe 4 is provided on the discharge pipe 4. For the bar valve, two rows of supporting columns 5 are arranged on the sides of the lower side of the material warehouse 1, and a symmetrically arranged supporting frame 6 is arranged on the inner side of the two rows of supporting columns 5, and a symmetrically arranged supporting platform 7 is arranged on the supporting frame 6. , the weighing bin 8 is set on the support platform 7, the top of the weighing bin 8 is open, and a row of material level switches is arranged inside the weighing bin 8, the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com