Automatic spraying device

An automatic spraying and sliding installation technology, applied in printing devices, printing, etc., can solve the problems of low product switching efficiency, poor spraying quality in border areas, and low spraying efficiency, so as to improve the functionality and effect of use, and increase the scope of application , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

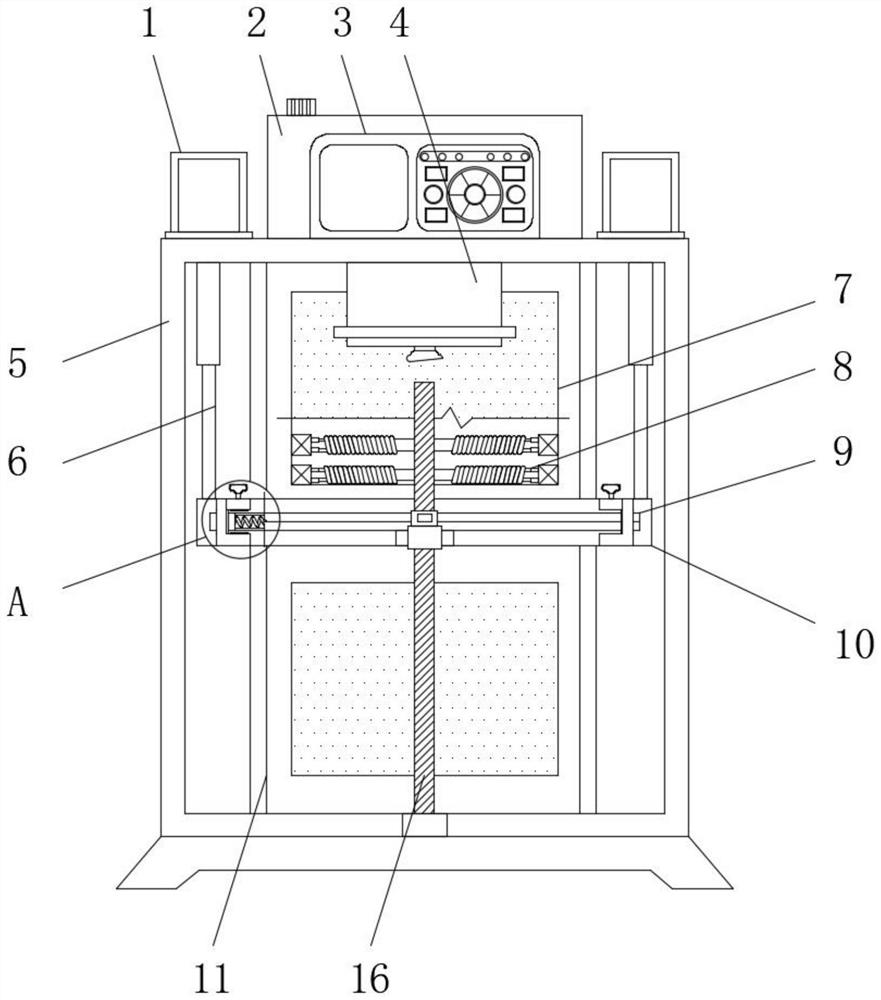

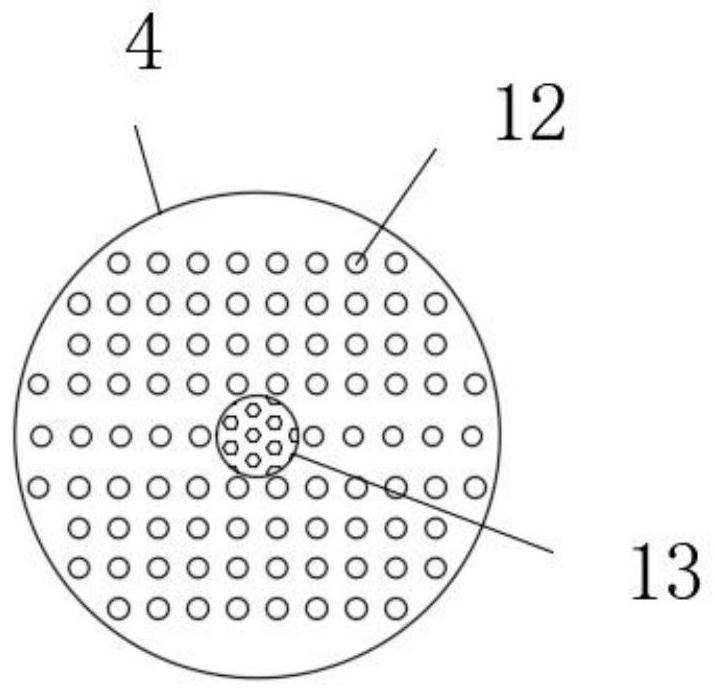

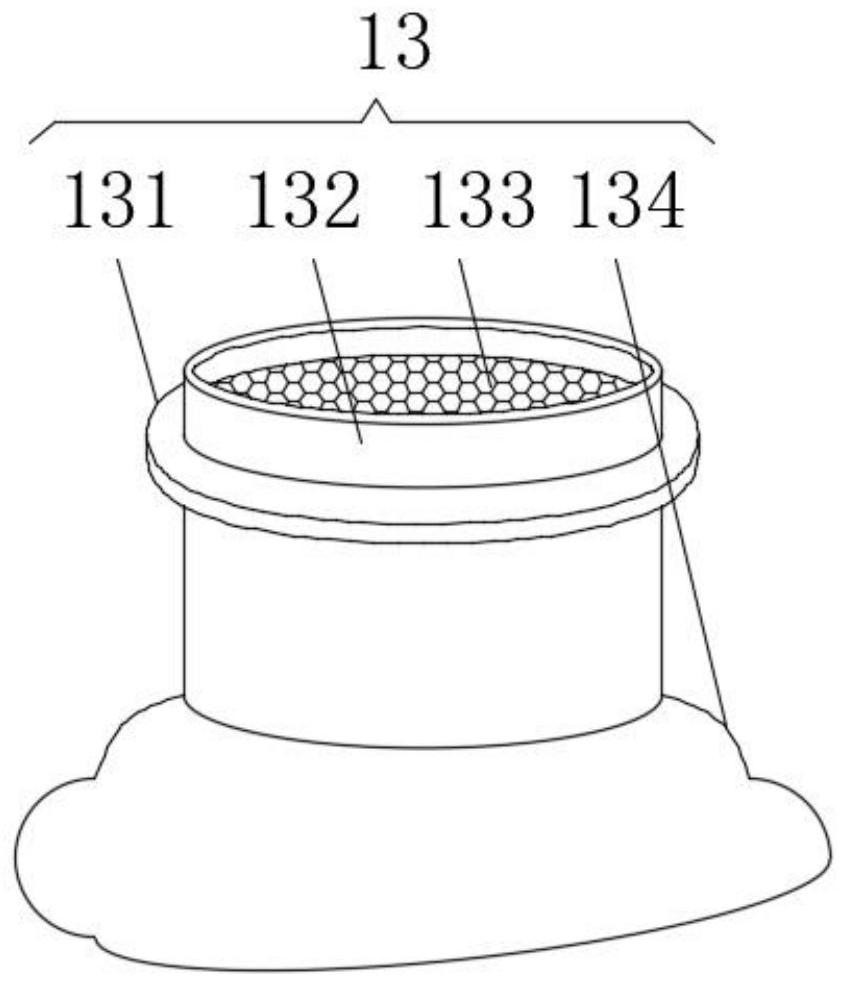

[0036] Such as Figure 1-8As shown, an automatic spraying device is provided in the embodiment, including a casing 5, a rotary spray head mechanism 13, a fixed assembly 14, a threaded rotary sleeve 17, an installation bottom sleeve 19 and a second built-in connection spring 22, the casing 5 An electric push rod 1, an ink tank 2 and a host computer 3 are fixedly installed on the top of the cabinet, and a paint sprayer 4 is fixedly installed on the inner top wall of the casing 5, and a mounting hole is provided at the center of the paint sprayer 4 for installation. A rotating spray head mechanism 13 is installed in the hole, and a number of spraying holes 12 are arranged on the bottom surface of the paint sprayer 4. A telescopic rod 6 is installed on the output end of the electric push rod 1, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com