A processing mechanism for sheet metal used in electric motor shells

A technology of motor casing and processing mechanism, which is applied in the field of sheet metal processing, can solve the problems of low processing efficiency and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

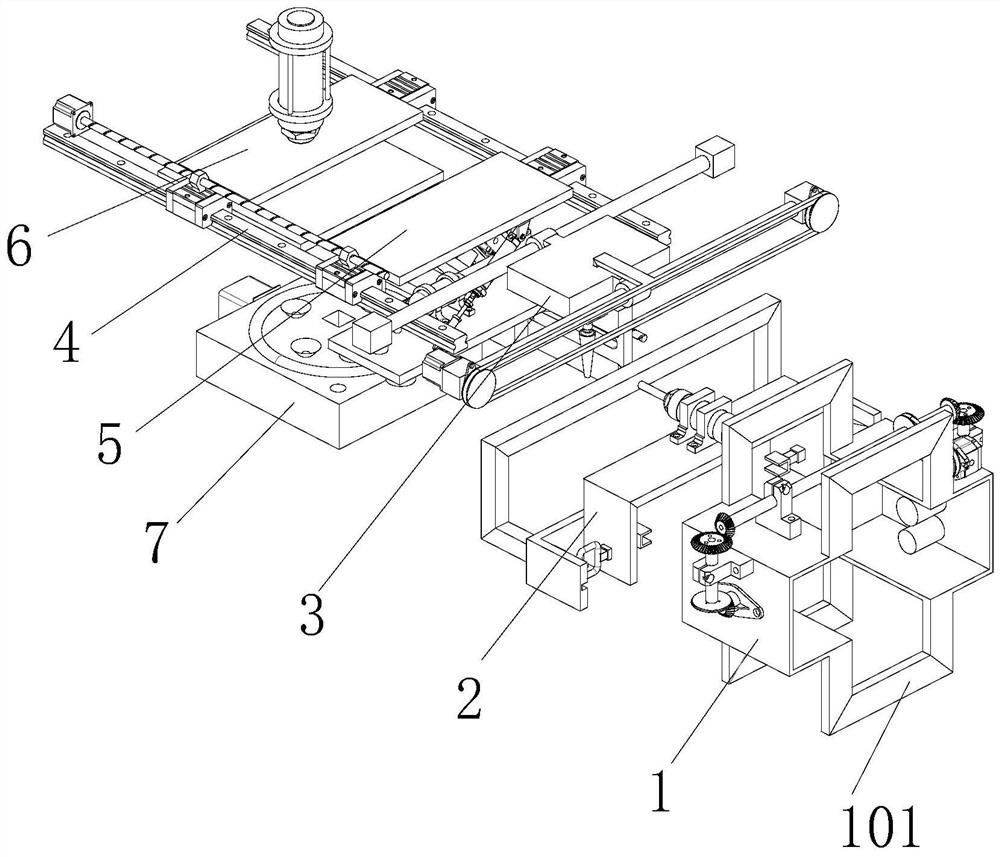

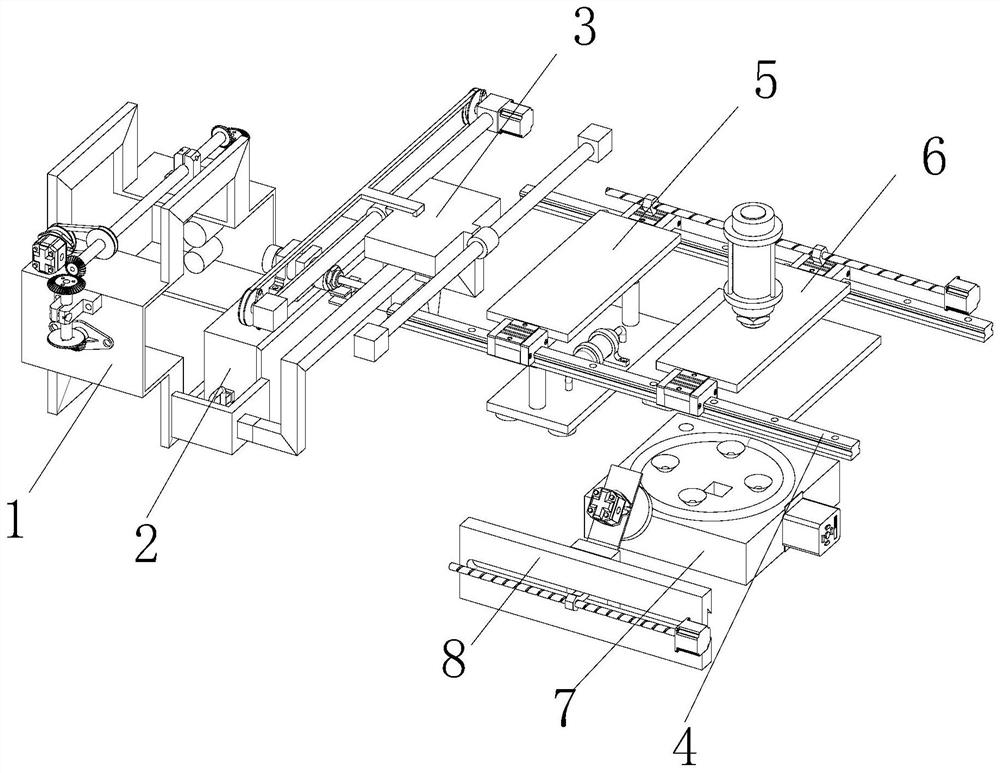

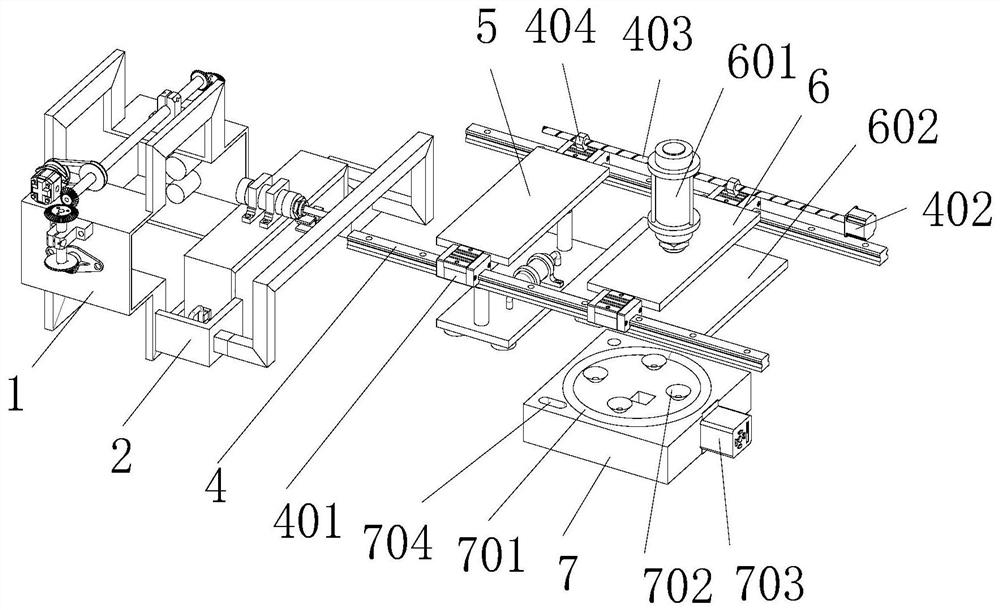

[0031] Referring to Fig. 1 to Fig. 10, a processing mechanism of sheet metal for a motor casing, comprising a feeding frame 1, the feeding

[0032] The whole piece of sheet metal is inserted through the middle of the four feed rollers 102, that is, each side of the sheet metal is fed from two feed rollers

[0037] The side of the cutting assembly 3 away from the middle arm 204 is provided with two hoisting guide rails 4, and the hoisting guide rails 4 are opposite to the transverse guide rails.

[0043] For example, in order to facilitate the grinding of the sheet metal on the base 7, the grinding assembly 8 includes a strip-shaped side plate 801, the strip-shaped side

[0044] The stepping motor 809 drives the sliding table 802 to slide along the sliding groove 803 by advancing the screw 810.

[0045] When in use, the whole piece of sheet metal is inserted through the middle of the four feeding rollers 102, and the feeding motor 111 passes through the feeding

[0046] The laser ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com