Hinge beam assembly and novel cubic press

A technology of six-sided top press and hinged beam, which is applied to the application of ultra-high pressure process, the method of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., which can solve the difficulty of forging and processing hinged beams, hinges, etc. The single weight of the beam equipment becomes larger and the pressure control is difficult to improve, so as to achieve the effect of improving the pressure bearing capacity and sealing performance, reducing the synthesis cost and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe in detail the embodiments of the present invention and their beneficial effects in conjunction with the accompanying drawings.

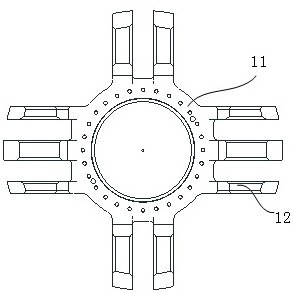

[0034] like figure 1 , Figure 4 and Figure 5 As shown, one embodiment of the present invention provides a hinge beam assembly.

[0035] Specifically, the hinged beam assembly includes: hinged beam 10, spherical plunger 20, film 30, guide sleeve 40, guide block 21, top hammer 22, spacer 23, hinged beam 10 includes cylinder body 11 and is arranged around the cylinder body 11. The lugs 12 on the outer wall, the cylinder body 11 has a first inner hole 111; the spherical plunger 20 is arranged in the first inner hole 111, the spherical plunger 20 is in a hemispherical shape, the bottom wall 113 of the first inner hole 111 and A pressurized chamber is formed between the spherical plungers 20, and an oil inlet hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com