A synchronous self-centering liftable linear cutting banana drop-comb device

A straight-line cutting and self-centering technology, used in transportation and packaging, vehicle parts, casters, etc., can solve the problems of poor adaptation of banana cob shafts, easy damage to banana combs, and low combing efficiency, avoiding mechanical damage, The effect of reducing labor force and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

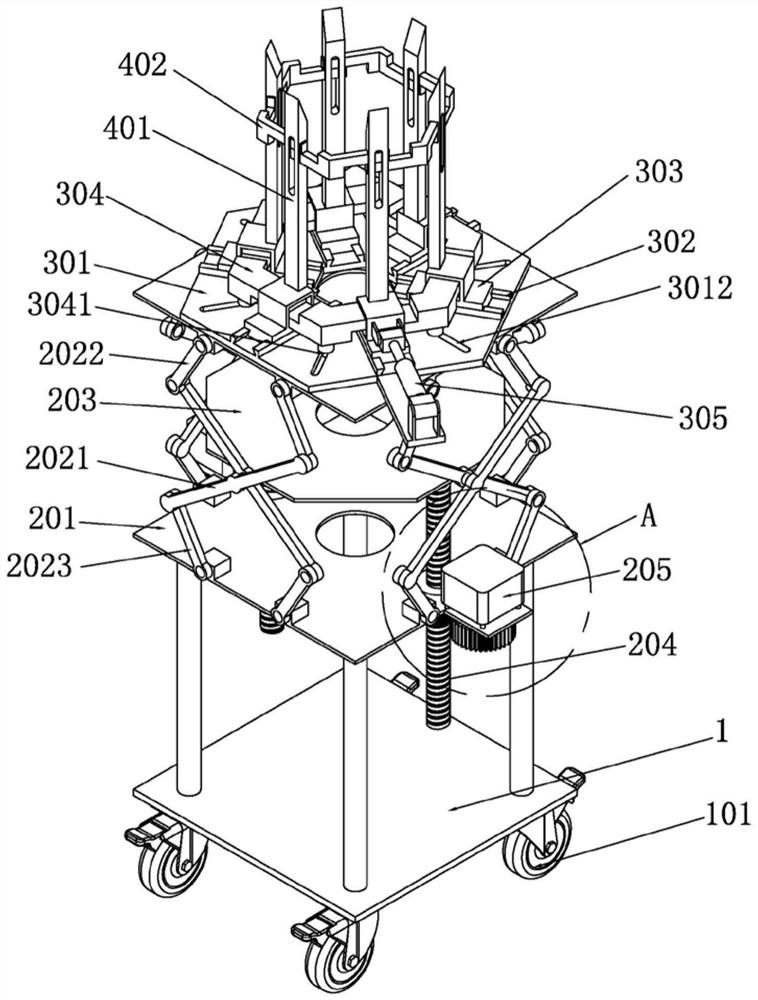

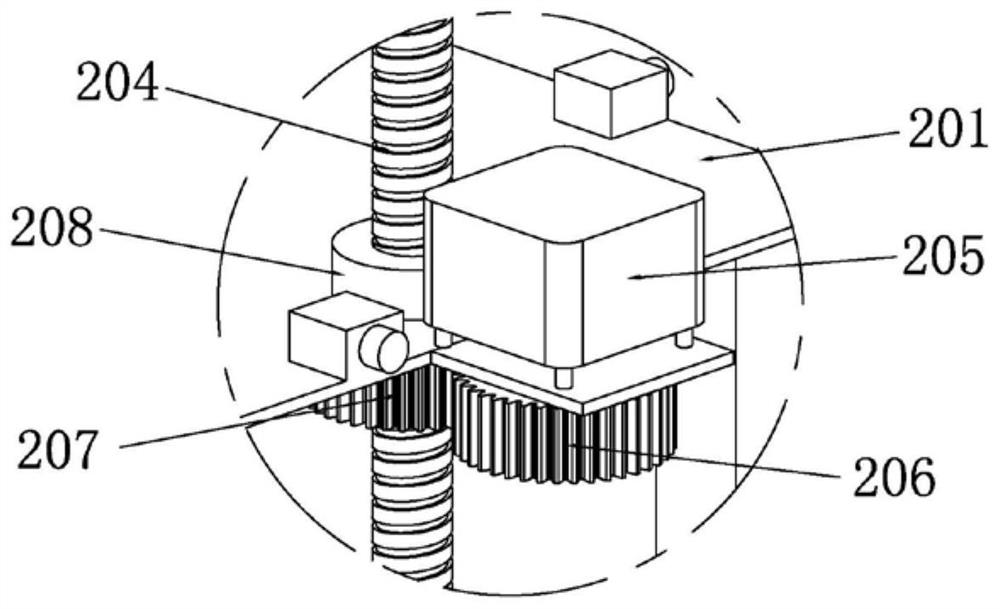

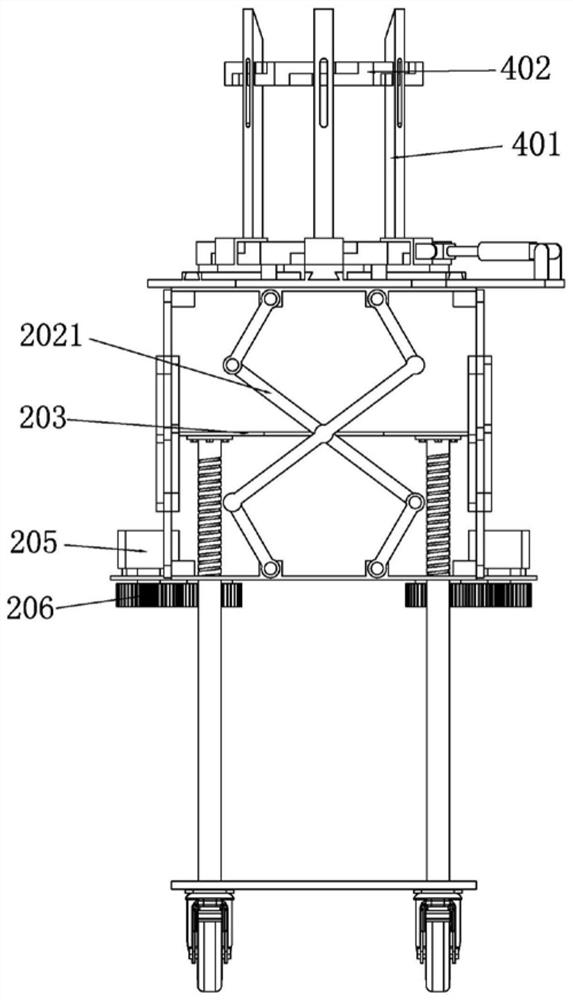

[0020] Such as Figure 1 to Figure 4 As shown, the synchronous self-centering liftable linear cutting type banana combing device described in this embodiment includes a frame 1, a lifting mechanism, a synchronous self-centering variable diameter mechanism and a cutting tool set; the bottom of the frame 1 Universal wheels 101 are installed for easy movement; the lifting mechanism is mounted on the frame 1 and can move up and down driven by its lifting power source 205; the synchronous self-centering variable diameter mechanism is mounted on the lifting mechanism and It can move up and down synchronously with the lifting mechanism, and the synchronous self-centering diameter-reducing mechanism can be expanded or folded under the drive of its diameter-reducing power source 305; the cutting tool is assembled on the synchronous self-centering diameter-reducing mechanism, and can fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com