Industrial control system of stacker crane

An industrial control system and palletizer technology, applied in the field of industrial control systems, can solve the problems of large structural loss, low work efficiency and high requirements of the mechanical arm, and achieve the effect of improving the service life of the equipment, reducing the maintenance cost and simplifying the action path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

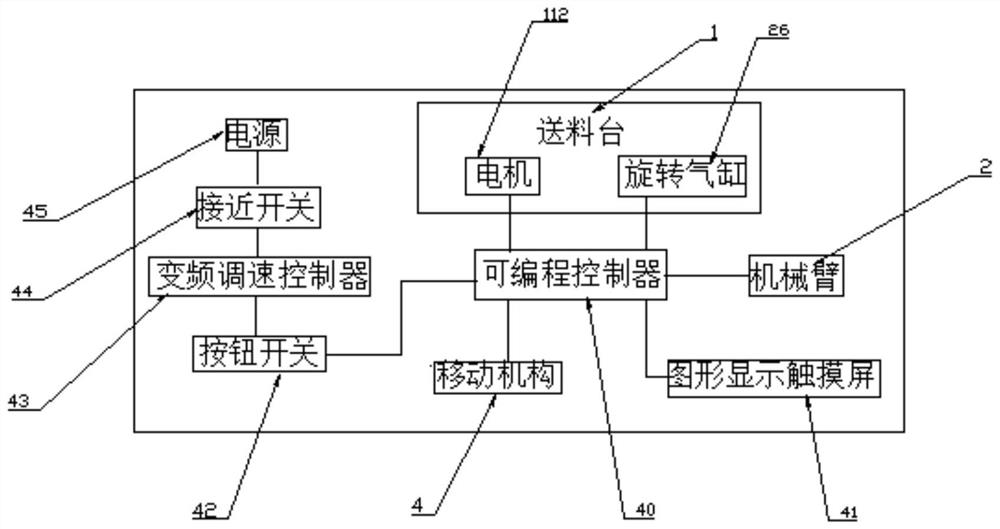

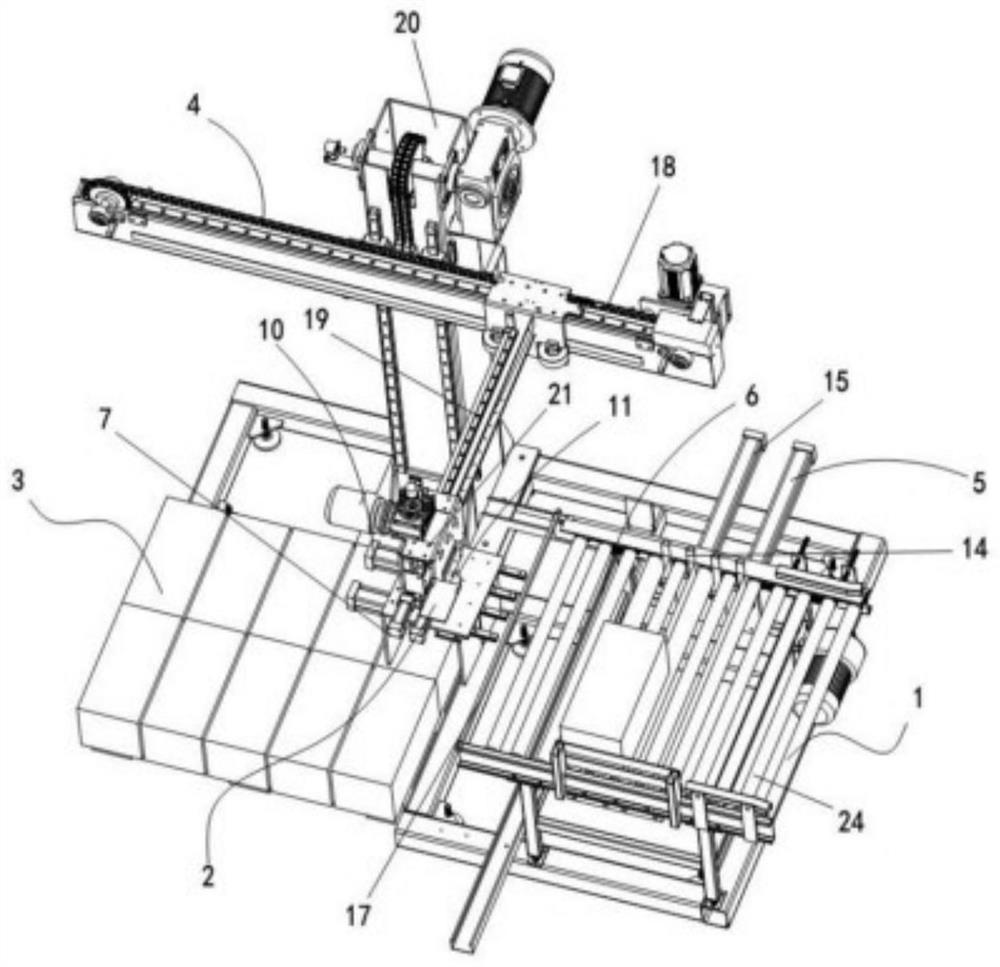

[0023] Example 1, such as figure 1 , 2 The industrial control system of a kind of palletizer shown, it comprises programmable logic controller (40), frequency conversion speed regulation controller (43), proximity switch (44), button switch (42), terminal block and graphic display touch screen ( 41), the external power supply (45) is connected to the button switch (42) and the frequency conversion speed controller (43) successively, and the described frequency conversion speed controller (43) is connected to the proximity switch (44) and the programmable controller (40) successively ), the port of the programmable controller (40) is respectively connected to the motor (112) and the rotary cylinder (26) of the feeding table (1) of the conveying material of the palletizer through the terminal block, the mechanical arm (2) of the clamping material ), the moving mechanism (4) of the omnidirectional mobile mechanical arm (18), the driving mechanism (10) of the claw head (7), the r...

Embodiment 2

[0024] Example 2, such as figure 1 , 2 The industrial control system of a kind of palletizer shown, it comprises programmable logic controller (40), frequency conversion speed regulation controller (43), proximity switch (44), button switch (42), terminal block and graphic display touch screen ( 41), the external power supply (45) is connected to the button switch (42) and the frequency conversion speed controller (43) successively, and the described frequency conversion speed controller (43) is connected to the proximity switch (44) and the programmable controller (40) successively ), the port of the programmable controller (40) is respectively connected to the motor (112) and the rotary cylinder (26) of the feeding table (1) of the conveying material of the palletizer through the terminal block, the mechanical arm (2) of the clamping material ), the moving mechanism (4) of the omnidirectional mobile mechanical arm (18), the driving mechanism (10) of the claw head (7), the r...

Embodiment 3

[0025] Example 3, such as figure 1 , 2 The industrial control system of a kind of palletizer shown, it comprises programmable logic controller (40), frequency conversion speed regulation controller (43), proximity switch (44), button switch (42), terminal block and graphic display touch screen ( 41), the external power supply (45) is connected to the button switch (42) and the frequency conversion speed controller (43) successively, and the described frequency conversion speed controller (43) is connected to the proximity switch (44) and the programmable controller (40) successively ), the port of the programmable controller (40) is respectively connected to the motor (112) and the rotary cylinder (26) of the feeding table (1) of the conveying material of the palletizer through the terminal block, the mechanical arm (2) of the clamping material ), the moving mechanism (4) of the omnidirectional mobile mechanical arm (18), the driving mechanism (10) of the claw head (7), the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com