Multi-phase mixed material split-phase collection device and split-phase collection method and application thereof

A collection device and multi-phase mixing technology, which is applied in the direction of measuring devices, analysis materials, test samples preparation, etc., can solve the problem of unable to sample Fischer-Tropsch synthesis products, achieve flexible and controllable material phases, save device space and Equipment investment, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

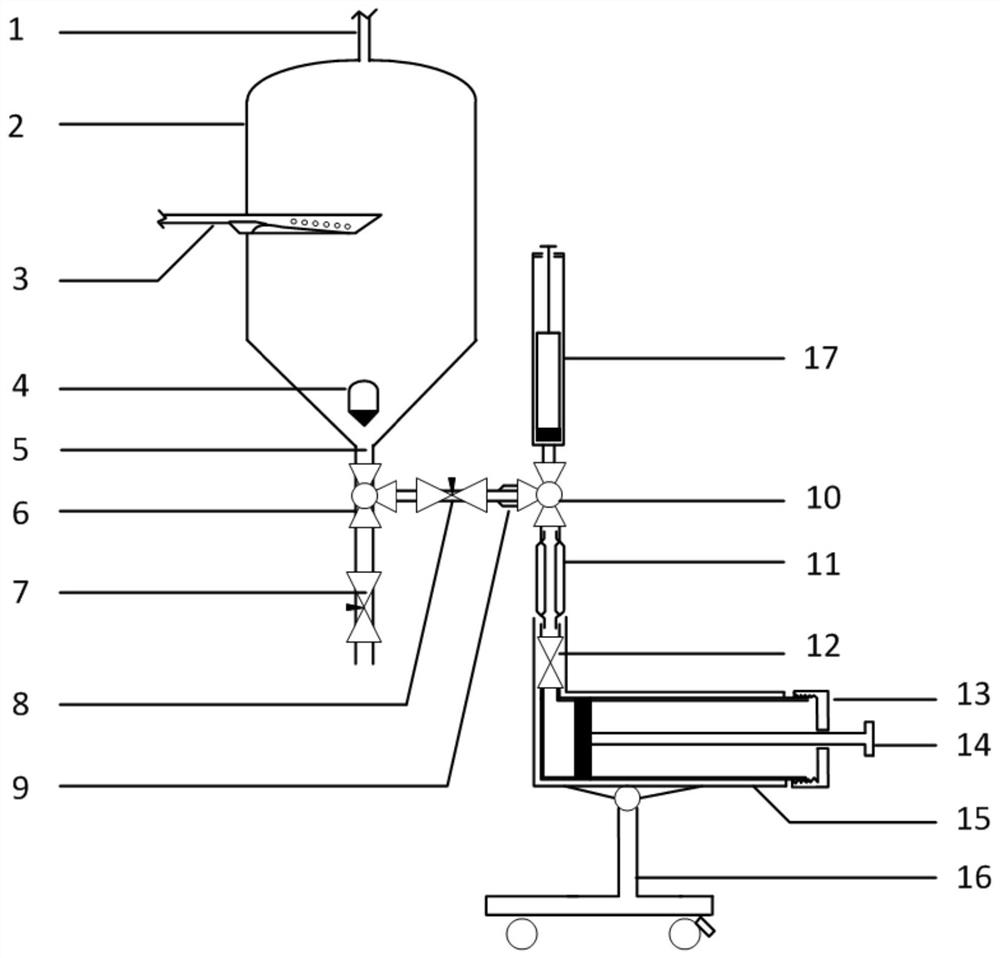

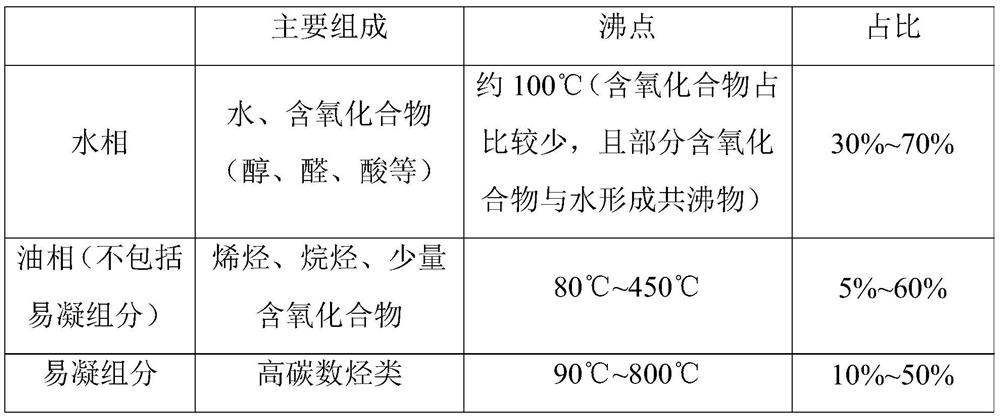

[0096] use figure 1 and figure 2 The shown phase-separation collection device carries out phase-separation collection to the Fischer-Tropsch synthesis product shown in Table 1, and the specific device structure and operation mode are not described in detail, and the following parameters are specifically set:

[0097] (1) Tank 2: diameter is 10cm, height is 30cm, operating temperature is 120°C;

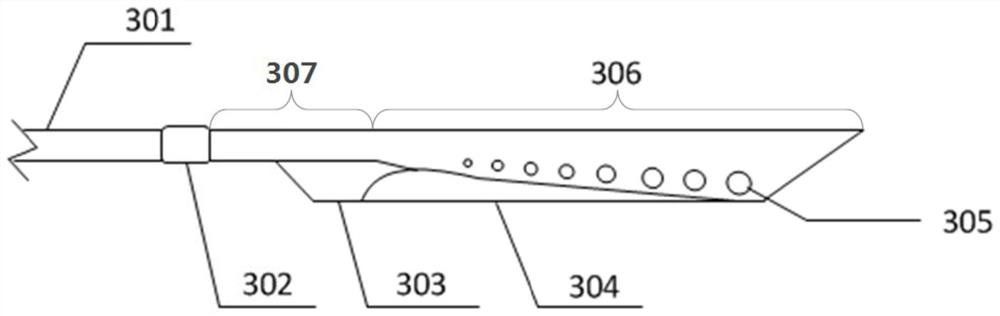

[0098] (2) Variable-diameter gas distribution pipe: the length of the gradual change section 306 is the radius of the tank body 2, and the angle of the gradual change angle is 15°. A row of gas distribution holes 305 are distributed on the gradual change section 306. Along the flow direction, the first hole The diameter of the hole is 1.2mm, the diameter of the next hole is 1.1 times the diameter of the previous hole, and the distance between each two holes is twice the sum of the diameters of the two holes;

[0099] (3) Observation window 11: the inner tube is made of tempered glas...

Embodiment 2

[0103] According to the phase separation collection device and operation method of Example 1, the difference is that no variable-diameter gas distribution pipe is provided, but the product pipeline 301 is directly connected to the inside of the tank.

[0104] The first gas phase is collected from the first gas phase outlet, the second gas phase is collected from the second gas phase collector, and the second liquid-solid phase is obtained from the second liquid-solid phase collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com