Pointer type differential pressure gauge calibration device

A calibration device and micro-differential pressure technology, which is applied to measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of large calibration errors of pointer-type differential pressure gauges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

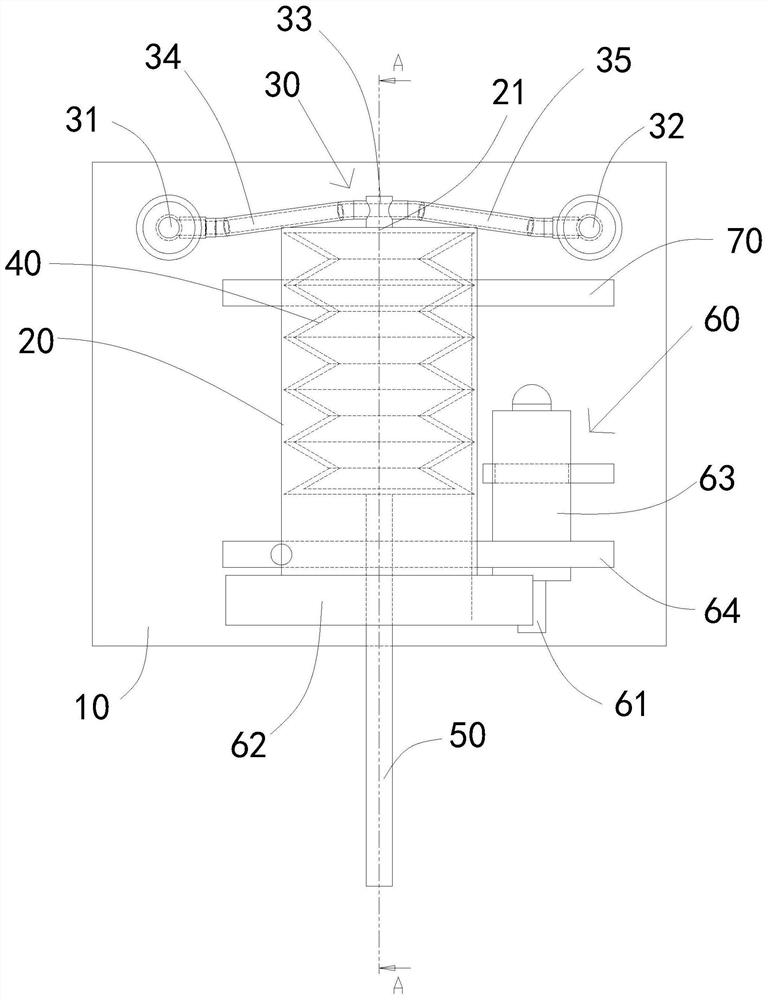

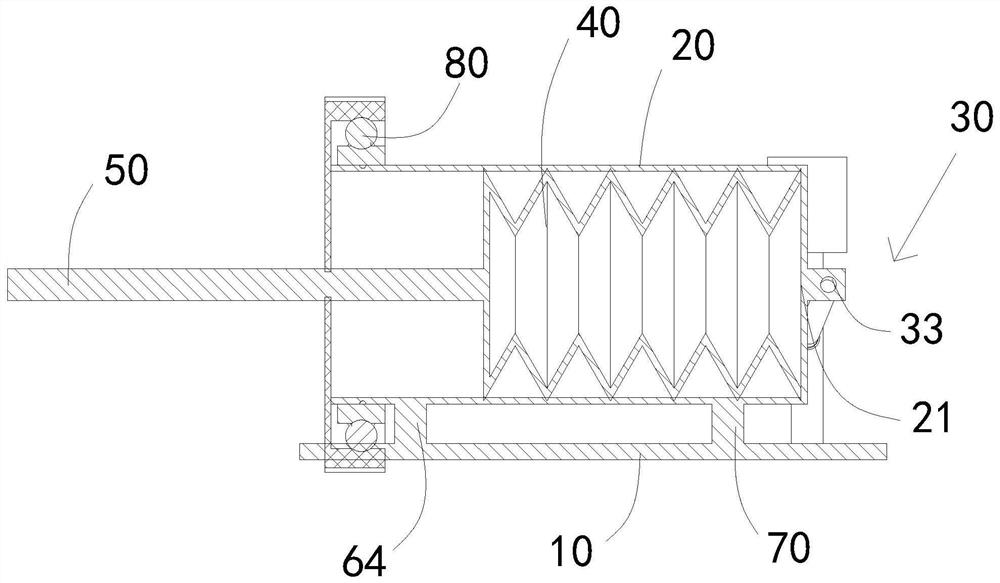

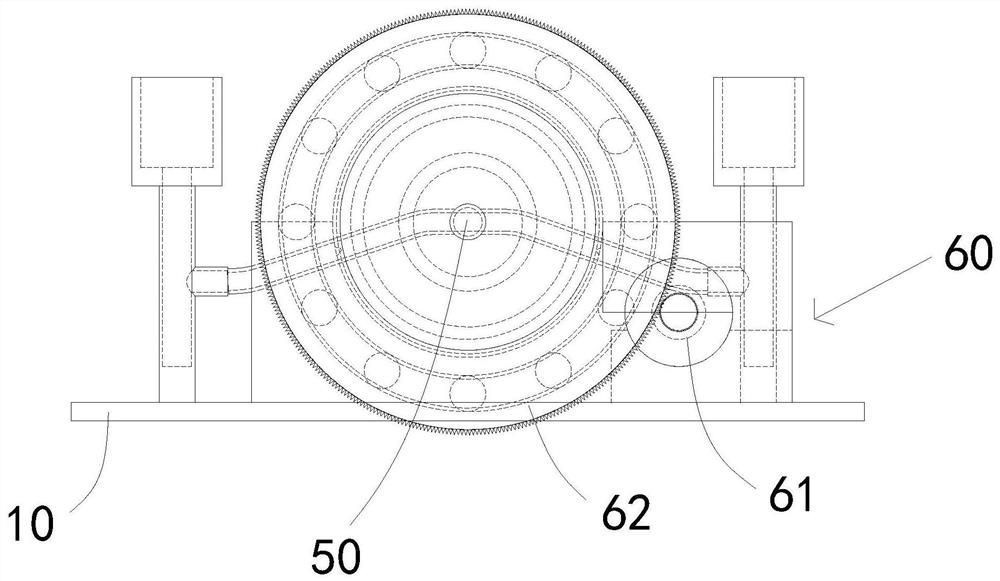

[0032] The invention provides a pointer type differential pressure gauge calibration device, the embodiment of which is Figure 1 to Figure 3 As shown, it includes a substrate 10, and a housing 20, a pressure equalizing mechanism 30, a bellows 40, a screw 50 and a driving mechanism 60 arranged on the substrate 10; The input end of the mechanism 30 is connected and conducted, and the two output ends of the pressure equalizing mechanism 30 are respectively connected with the connection port 31 of the standard device and the connection port 32 of the meter to be verified; The air guide hole 21 is connected and conducted, and the outside of the bellows 40 is connected with the screw rod 50; the driving mechanism 60 is connected with the screw rod 50, and the driving mechanism 60 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com