Method for analyzing operation energy efficiency of refrigerating machine room and achieving high efficiency and energy conservation after optimization

A high-efficiency and energy-saving technology for refrigerating machine rooms, applied in heating methods, mechanical equipment, heating and ventilation control systems, etc., can solve the problems of lack of system operation efficiency indicators, inability to save energy, low energy efficiency of the system, etc., and achieve simple construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Energy efficiency analysis of refrigeration machine room operation and methods to achieve high efficiency and energy saving after optimization, including: original design energy efficiency simulation, design technology implementation plan, equipment selection optimization, pipeline optimization, group control system optimization, machine room installation and construction, machine room equipment commissioning, energy efficiency Certification acceptance and operation and maintenance management;

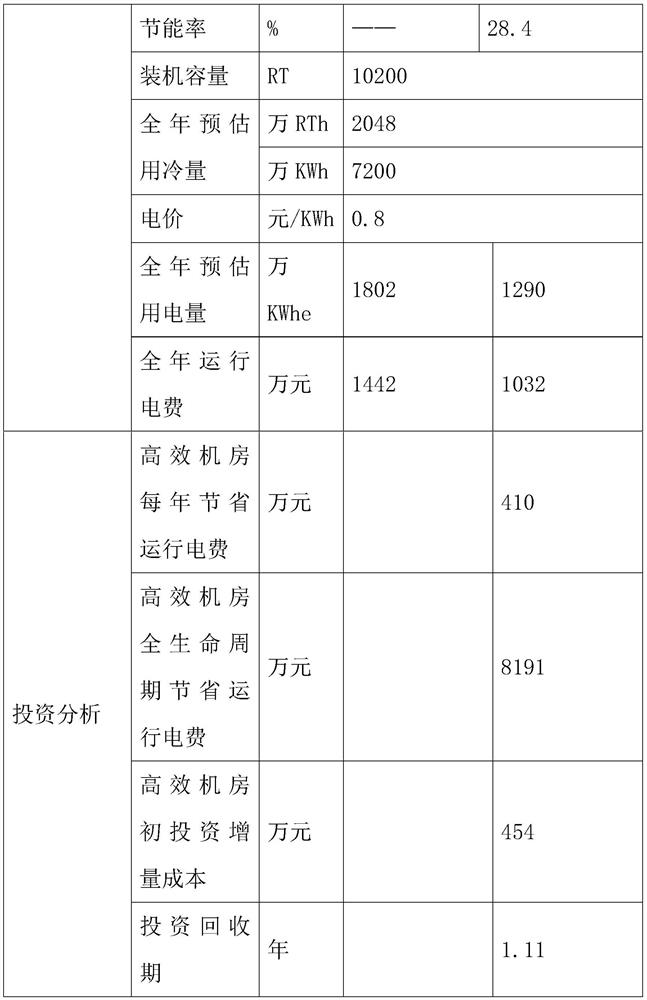

[0037] The energy efficiency simulation of the original design includes simulating the energy efficiency of the original design of the refrigeration room according to the ASHARE standard. The main parameters of the input equipment are used in conjunction with the Hourly Analysis Program software to carry out the annual load energy simulation to estimate the cooling capacity. EER of the refrigeration room = the total annual cumulative cooling consumption amount / annual cumulative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com