Control method and system of battery loop water pump and vehicle

A control method and control system technology, which is applied in the field of water pump control, can solve problems such as battery loop water pump leakage, stability impact, and battery module safety, and achieve the effect of ensuring safety and reasonable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

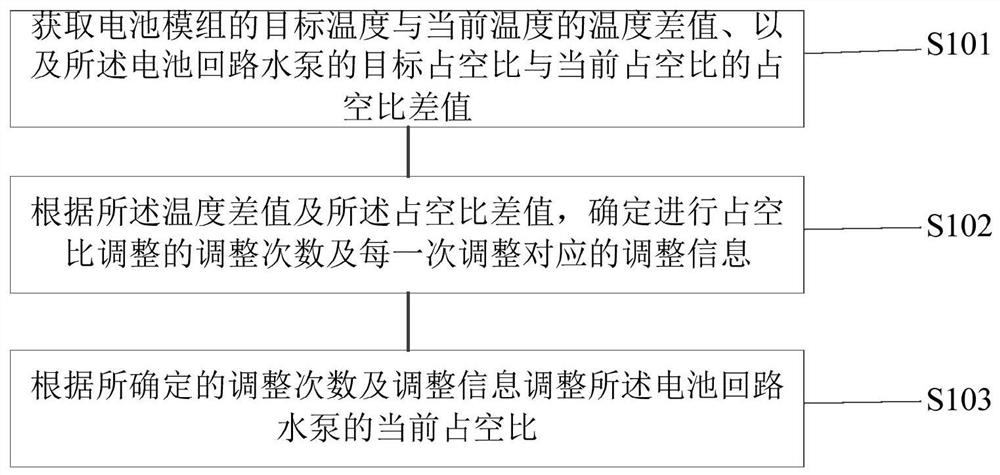

[0033] figure 2 It is a flow chart of a control method of a battery loop water pump in embodiment 1, such as figure 2 As shown, the control method of the battery loop water pump includes:

[0034] S101. Obtain the temperature difference between the target temperature of the battery module and the current temperature, and the duty cycle difference between the target duty cycle of the battery loop water pump and the current duty cycle.

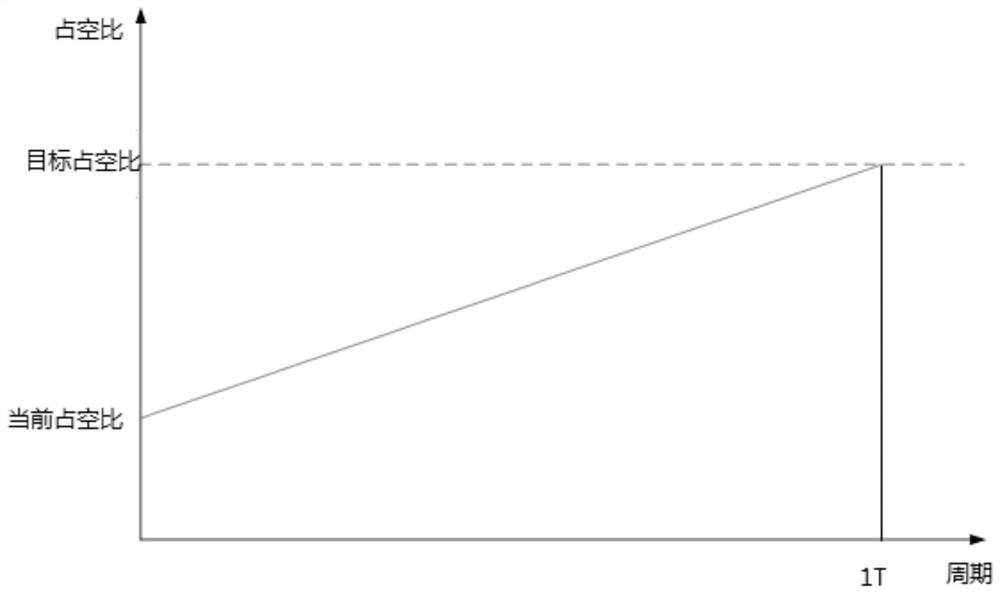

[0035] Wherein, the target temperature of the battery module is the temperature that the battery module needs to reach, and the acquisition method may include: directly acquiring a preset temperature threshold as the target temperature, and a preset duty cycle as the target duty Compare. The current temperature can be obtained directly through a temperature sensor provided on the battery module, and the current duty ratio can be obtained through calculation based on the ratio of the high level on the battery loop water pump to one cycle. Wh...

Embodiment 2

[0060] Figure 5 It is a module block diagram of the control system of the battery circuit water pump of the second embodiment.

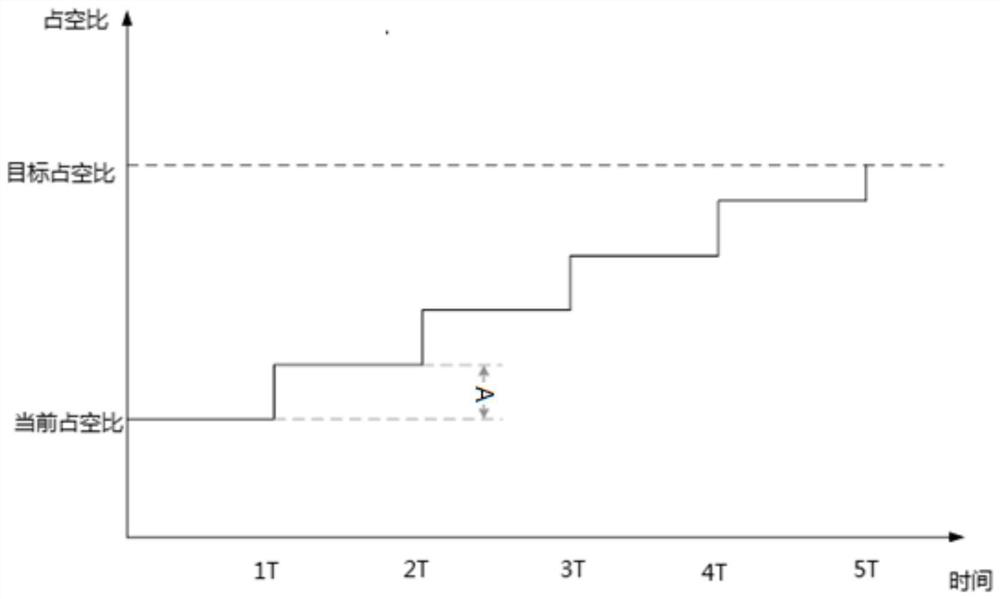

[0061] Such as Figure 5 As shown, the control system of the battery circuit water pump includes: a difference acquisition unit 1, which is used to obtain the temperature difference between the target temperature and the current temperature of the battery module, and the target duty ratio and the current duty ratio of the battery circuit water pump. The duty cycle difference of the duty cycle; the strategy determination unit 2, configured to determine the number of adjustments for duty cycle adjustment and the adjustment information corresponding to each adjustment according to the temperature difference and the duty cycle difference; and The adjustment unit 3 is configured to adjust the current duty cycle of the battery circuit water pump according to the determined adjustment times and adjustment information.

[0062] Preferably, the strategy de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com