Mounting structure of large-size cross beam on integrated steel and construction method

It is a technology of integrating section steel and installation structure, which is applied in the direction of building construction and construction, and can solve the problems of heavy welding workload, increased construction difficulty, and large welding smoke emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

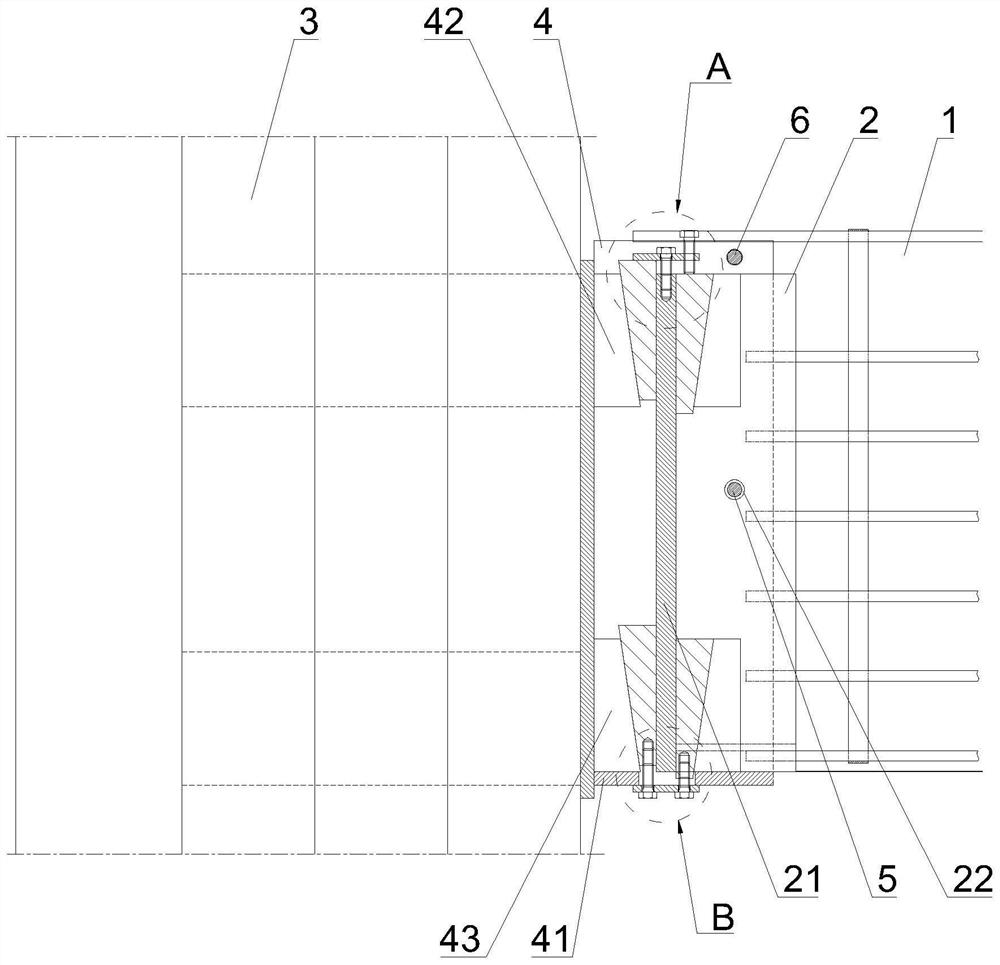

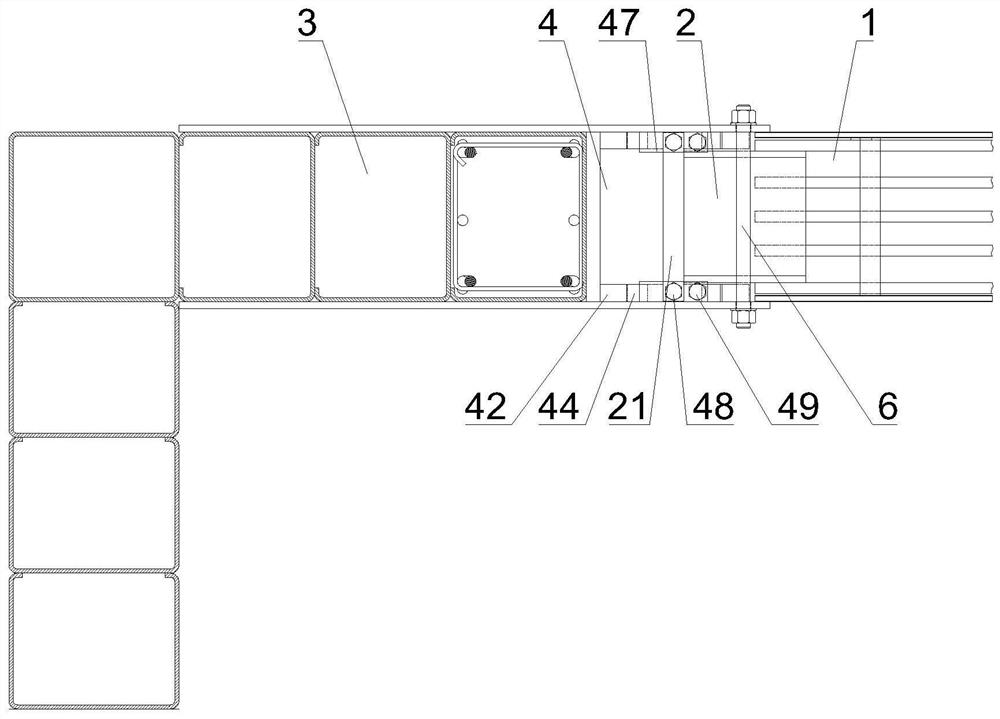

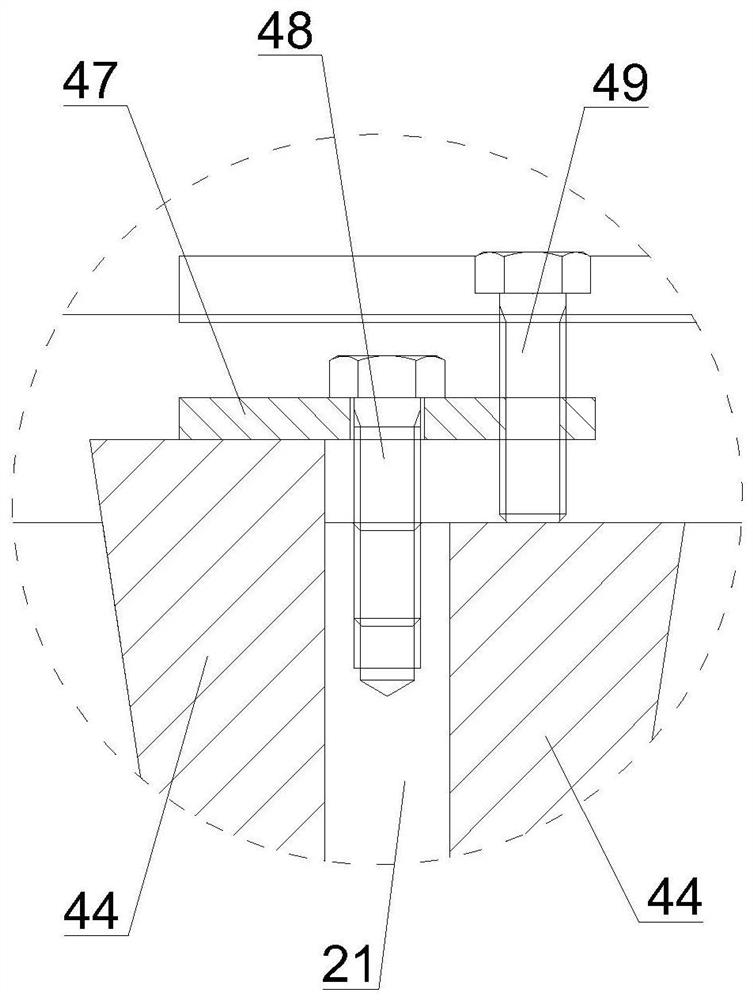

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0032] see Figures 1 to 6 As shown, this embodiment provides an installation structure for a large-size beam on an integrated section steel, wherein the end of the large-size beam 1 is provided with a reinforcement cage tenon 2 , and a limit edge 21 protrudes from the reinforcement cage tenon 2 . The large-size beam 1 includes thin-walled channel steel 11, steel bars 12 and hoops 13, several steel bars 12 are arranged in the cavity of the thin-walled channel steel 11 along the length direction of the thin-walled channel steel 11, and several hoops 13 are circumferentially Spot welded on the outer ring of each steel bar 12, the reinforcement cage tenon 2 is set against the bottom of the thin-walled channel steel 11, and the outer wall of the reinforcement cage tenon 2 is welded against the steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com