Thermal recycling industrial sewage treatment process

A technology for treating process and industrial sewage, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of waste of resources, increased cost of sewage treatment, and inability to collect and utilize sewage heat. , to achieve the effect of saving resources, improving efficiency, ensuring quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

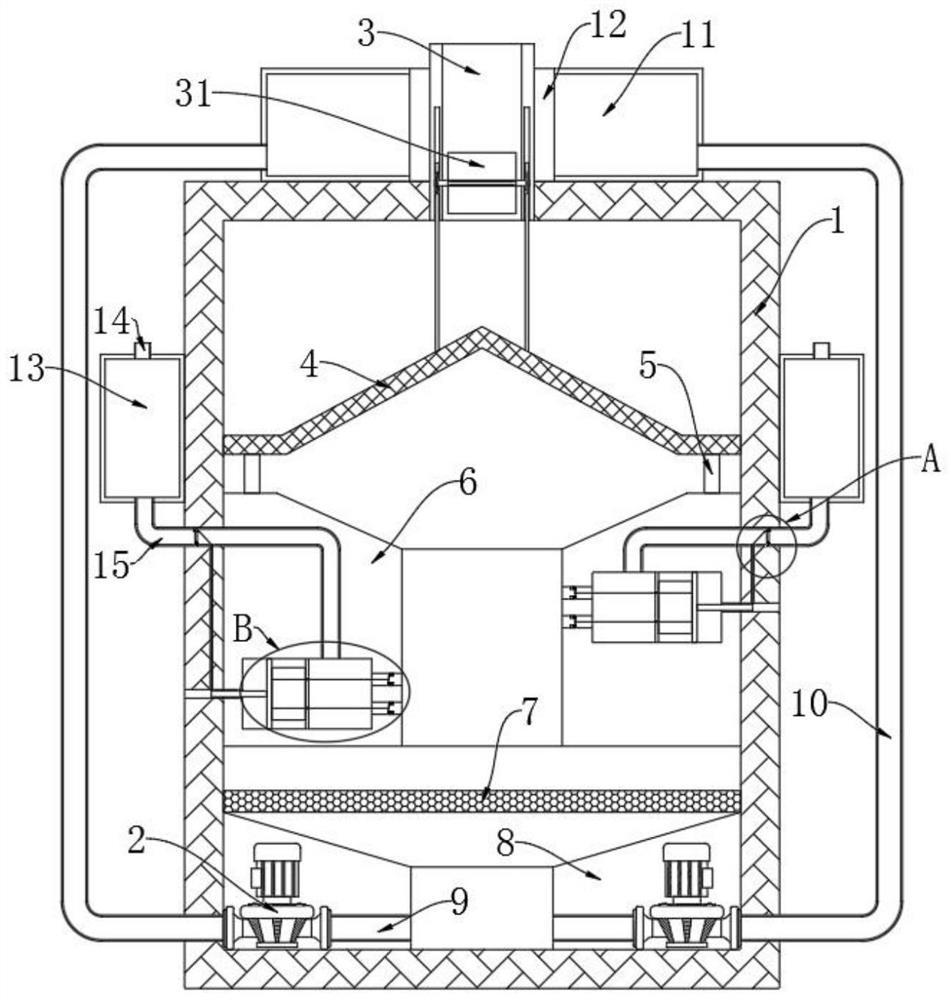

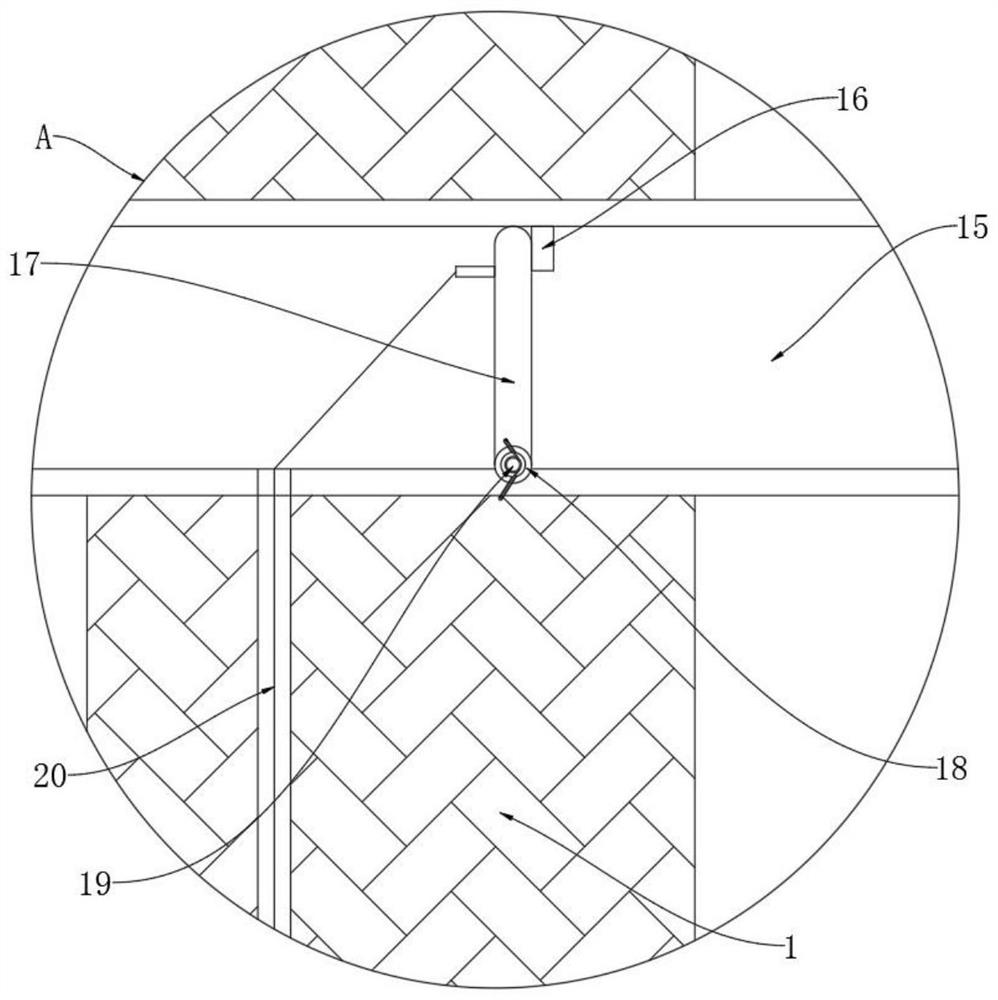

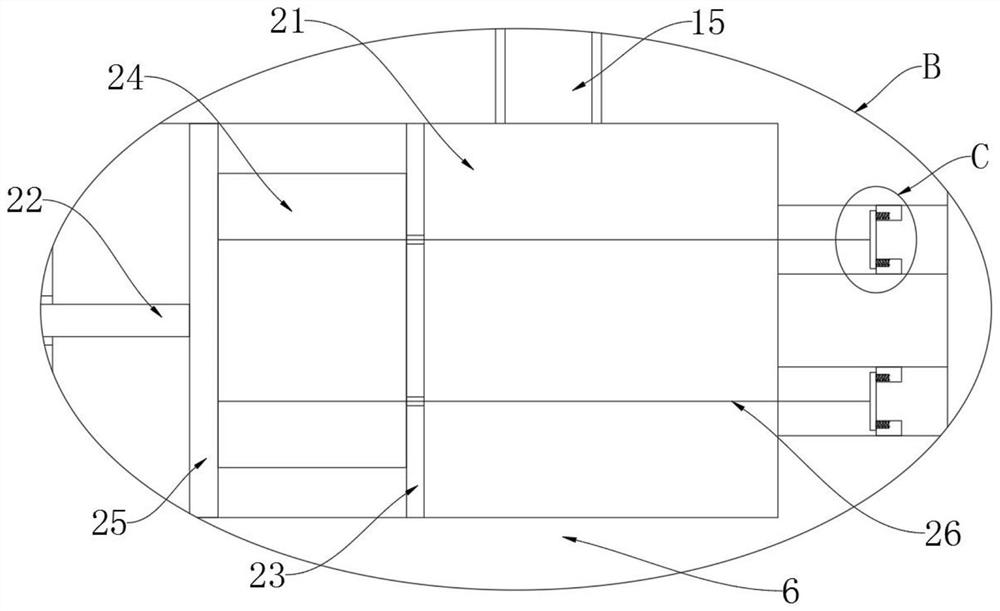

[0030] refer to Figure 1-6 , a thermal recycling industrial sewage treatment process, the steps are as follows;

[0031] S1: First, the sewage is pretreated. The pretreatment is carried out by the heat collection box. The sewage enters the device and is fully heated by the heat absorbed by the heat absorbing plate on the outer periphery of the device. After the pretreatment is completed;

[0032] S2: Filter the sewage. When the pretreated sewage flows through the filter, the large impurities in the sewage are filtered out by the filter, so that the sewage flows down through the filter. After the filtration is completed;

[0033] S3: The heat of the sewage is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com