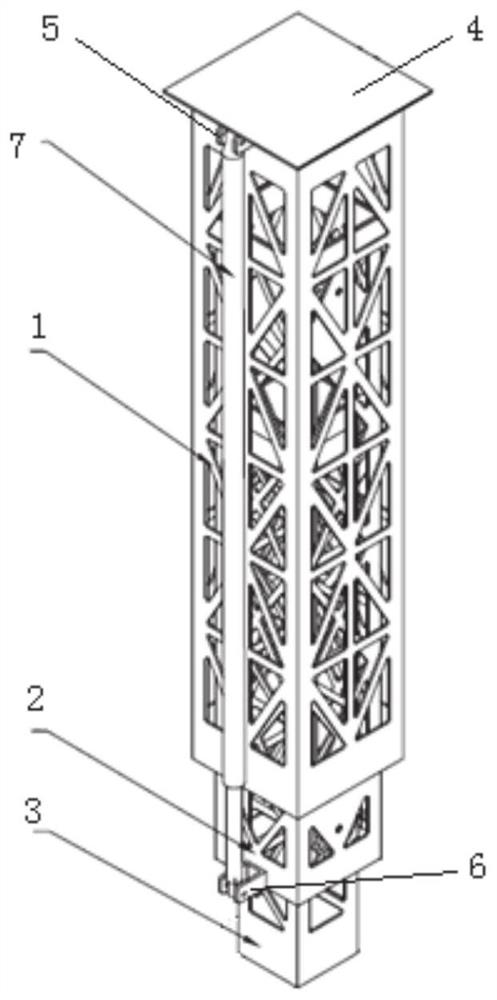

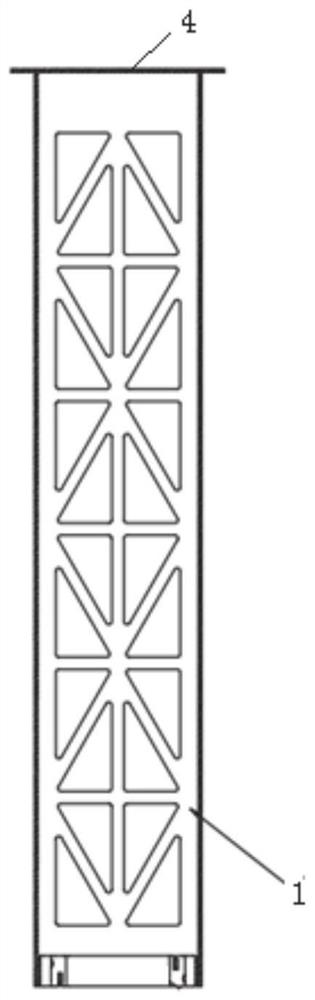

Telescopic mechanism and kitchen waste grabbing device

The technology of a telescopic mechanism and a telescopic arm, applied in the field of environmental protection equipment, can solve the problems that the wire rope is easy to come off the rope, easy to shake, and the grab is difficult to sink, and achieves the effect of not easily polluted, not easy to malfunction, and reduced impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] This embodiment discloses a food waste grabbing device, which includes the telescopic mechanism described in Embodiment 1. The bottom end of the third telescopic arm is connected to the grab bucket, which can drive the grab bucket to perform lifting movements. Other structures can adopt existing structures, and will not be described in detail here.

[0052] When the grabbing device of this embodiment is working, the telescopic mechanism drives the grab bucket to move, and the grab bucket grabs the slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com