Workpiece cleaning device for mechanical equipment machining and using method of workpiece cleaning device

A technology of mechanical equipment and cleaning devices, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, and can solve the problems of wasting cleaning fluid, reducing cleaning quality, and increasing cleaning time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

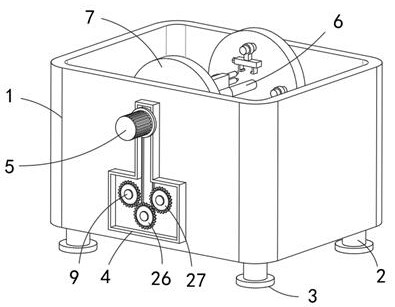

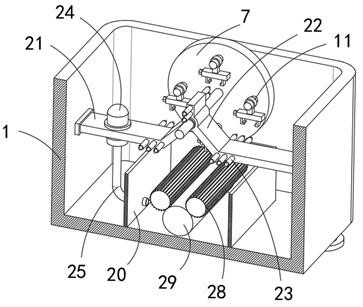

[0034] refer to Figure 1-7 , a workpiece cleaning device for mechanical equipment processing, comprising a cleaning housing 1, the lower end of the cleaning housing 1 is evenly connected with four vertical pillars 2, and the lower ends of the pillars 2 are fixedly connected with a ground-contact base 3, cleaning The side wall of the housing 1 is fixedly connected with a "convex" shaped casing 4, the side wall of the casing 4 is fixedly connected with a drive motor 5, and the output end of the drive motor 5 is fixedly connected with a first rotating shaft 6, and the first rotating shaft 6 is away from the One end of the drive motor 5 penetrates the shell 4 and is connected to the inner wall of the cleaning housing 1 in rotation. The outer wall of the first rotating shaft 6 in the cleaning housing 1 is fixedly sleeved with two vertical discs 7, and the two discs 7. A plurality of workpiece suspension mechanisms are provided on the opposite side walls. The workpiece suspension m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com