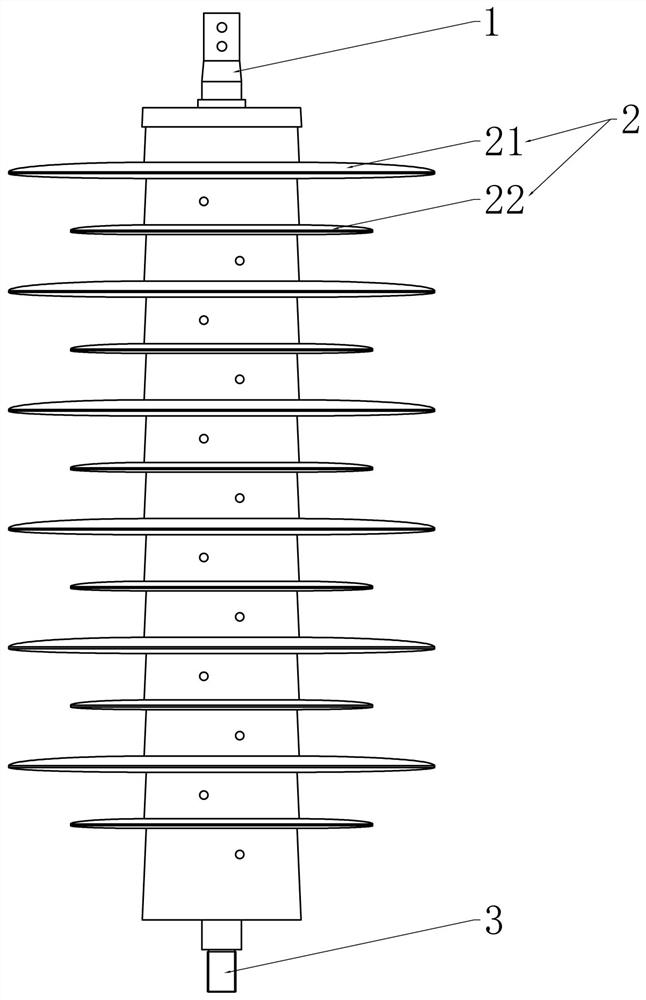

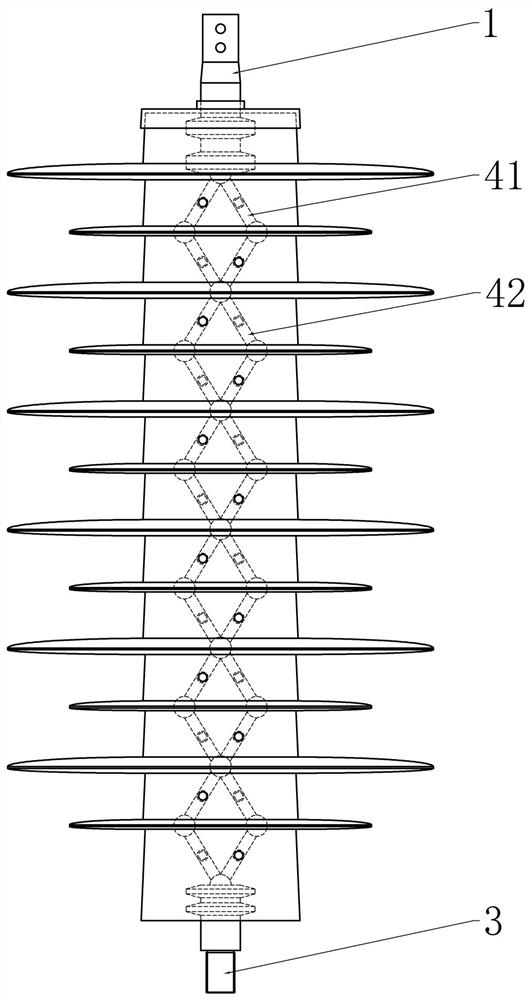

Manufacturing method of series gap lightning arrester

A technology with a series gap and a manufacturing method, applied in the field of arresters, can solve the problems of large leakage current and poor arc extinguishing effect, and achieve the effects of small leakage current, poor capacitance and reducing arc energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

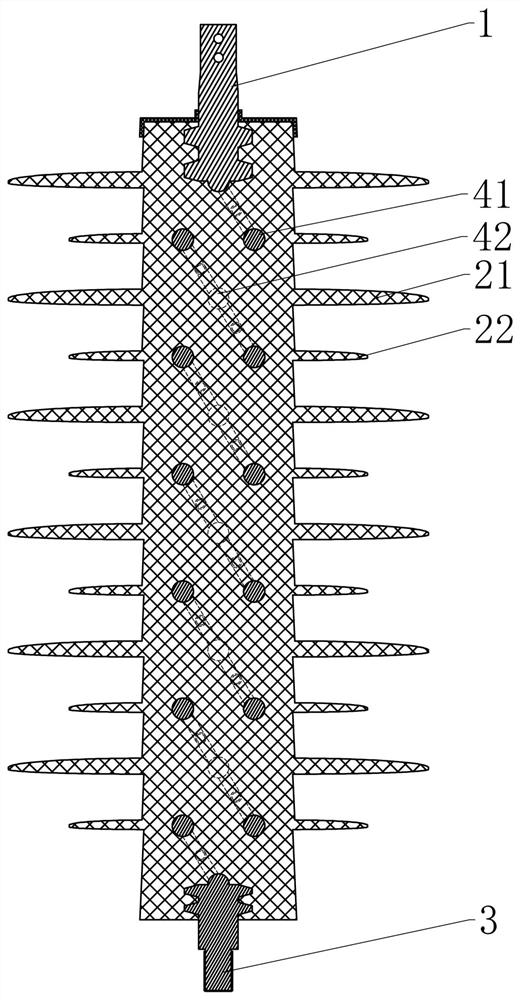

[0022] The present invention will be described in the form of embodiments below in conjunction with the accompanying drawings, so as to assist those skilled in the art to understand and realize the present invention. Unless otherwise stated, the following embodiments and technical terms therein should not be understood without departing from the background of technical knowledge in this technical field.

[0023] In the present invention, the two conductors at both ends of the gas discharge channel are A conductor and B conductor respectively.

[0024] The potential difference formula between the two plates of a parallel plate capacitor

[0025]

[0026] In the formula, U AB is the potential difference loaded between the two plates of the parallel plate capacitor, q is the amount of charge stored in the parallel plate capacitor C, d is the distance between the two plates of the parallel plate capacitor, ε 0 is the relative permittivity, and S is the area of each plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com