Fireproof and pressure-resistant rubber special-shaped cable and preparation process thereof

A preparation process and rubber technology, applied in the direction of cable/conductor manufacturing, insulated cable, flat/ribbon cable, etc., can solve the problems of poor stability, no thermal conductivity, cable damage, etc., and achieve poor stability and good thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

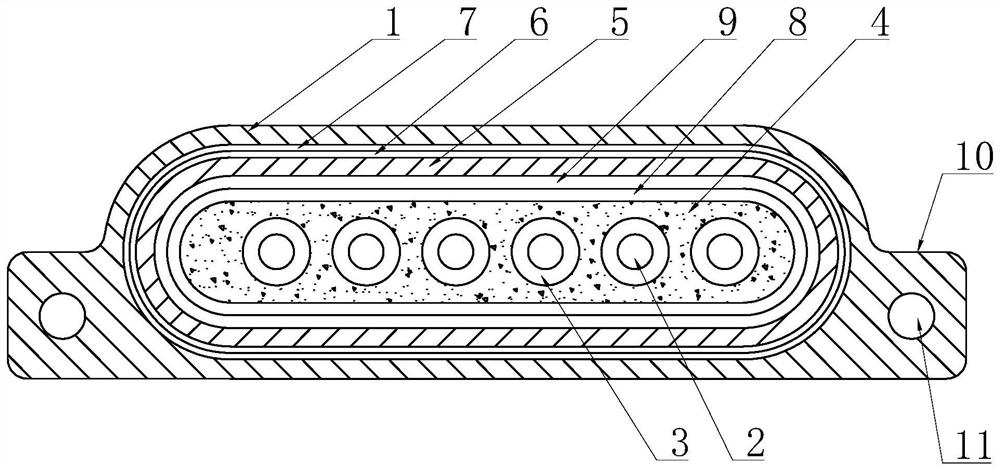

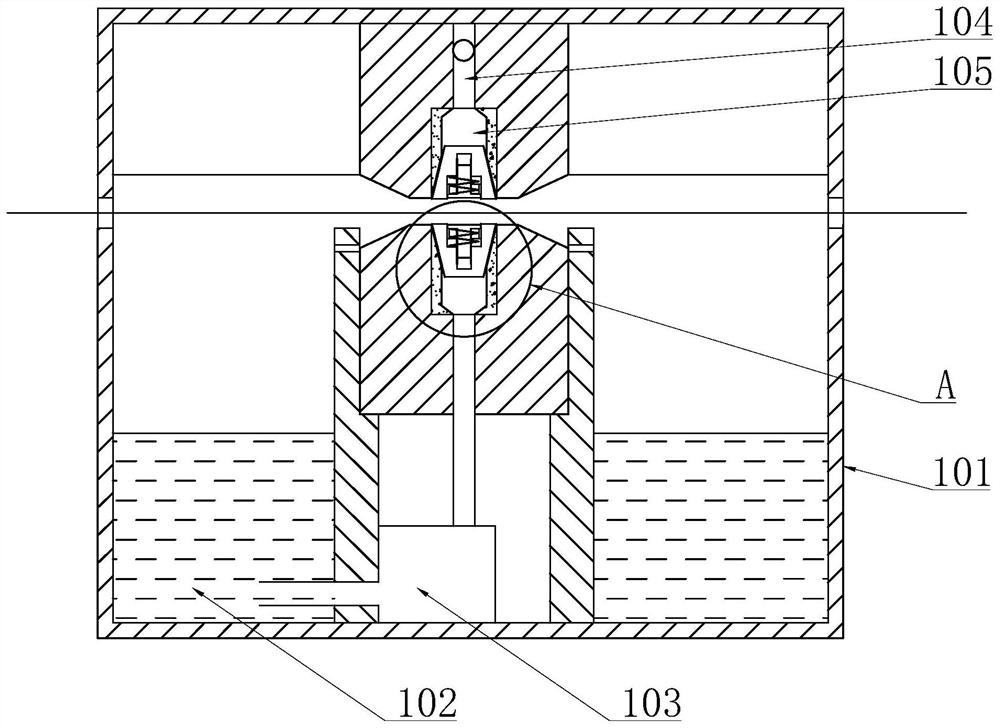

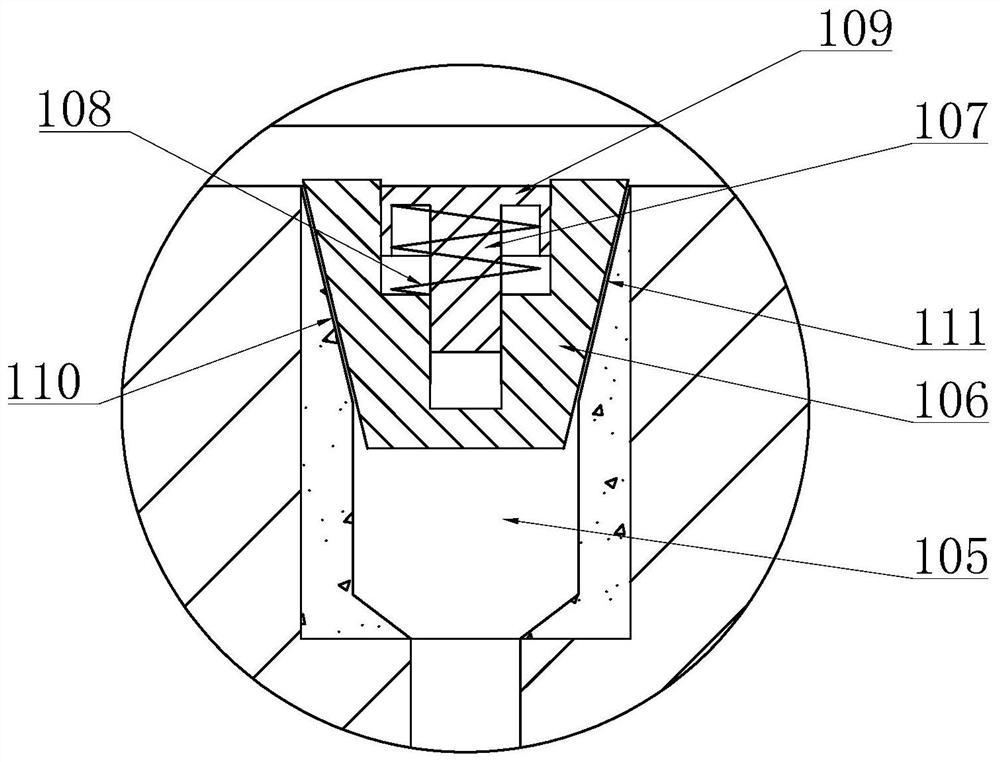

[0042] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-8 :

[0043] A fire-resistant and pressure-resistant rubber special-shaped cable, including an outer sheath 1 and several wires placed in the outer sheath 1, the wires include a wire core 2 and an insulating layer 3 coated on the outer wall of the wire core 2, and is characterized in that: The outer sheath 1 is provided with a flexible frame 4 with a flat structure, the wires are arranged horizontally and equidistantly and embedded in the flexible frame 4, and a flame-retardant sleeve 5 is also provided between the outer sheath 1 and the flexible frame 4, which is flame-retardant There is also a flame retardant filling layer between the sleeve 5 and the outer sheath 1 .

[0044] The flexible skeleton 4 is used to improve the extrusion resistance of the cable, and the flame retardancy is improved through the flame retardant sleeve 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com