Distributed train wheel set size detection system

A technology of size detection and train wheel, applied in the field of distributed train wheelset size detection system, which can solve the problems of peeling, wheel flange wear, and easy interference of line signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

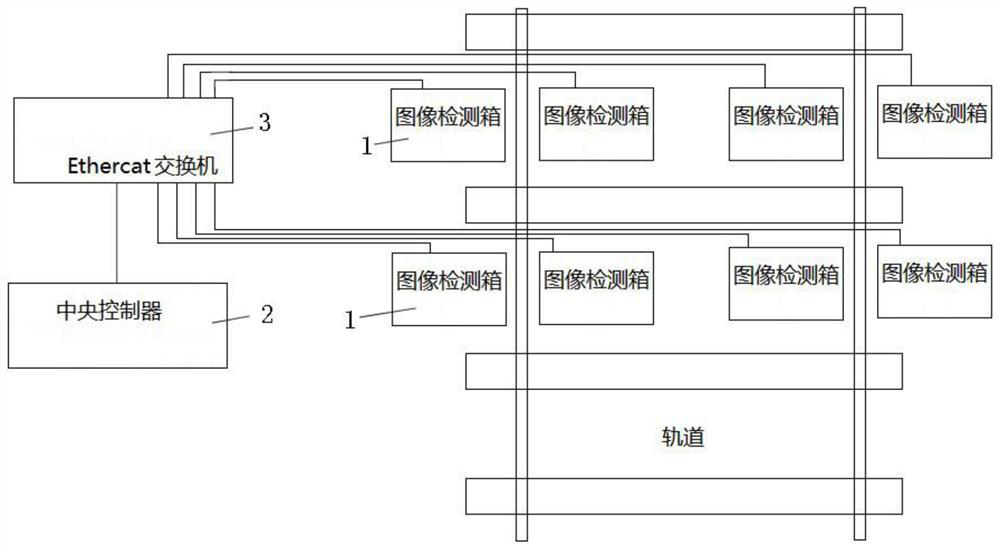

[0031] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The relevant components in the invention are not drawn according to the number, shape and size of the components in actual implementation. The type, quantity and proportion of each component in actual implementation can be changed arbitrarily, and the layout of the components may also be more complex.

[0032] See figure 1 , the distributed train wheelset size detection system of the present invention comprises connected:

[0033] Image detection box 1, used to obtain train wheelset images;

[0034] The central controller 2 is used to control the image detection box and detect the image of the train wheel set collected by the image detection box, and output the detection result of the size of the train wheel set;

[0035] The Ethercat communication unit 3 is used for communication between the image detection box 1 and the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com