Wind power flange connecting structure

A connection structure, wind power flange technology, applied in the direction of connection components, thin plate connection, wind power generation, etc., can solve the problems of inconvenient operation, increase the difficulty of construction, prolong the time of disassembly and assembly, so as to avoid flange separation and prevent dislocation , good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Next, a detailed description of the technical solutions in the embodiment of the present invention will be described in conjunction with the drawings of the present invention, which is apparent from the embodiments of the present invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor are the scope of the present invention.

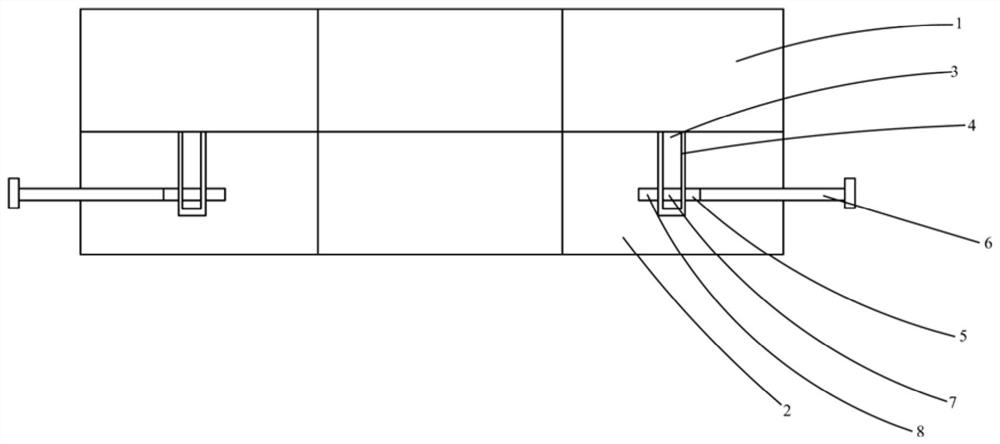

[0015]Participatefigure 1As shown, the connection structure of the wind power flange in the present embodiment includes the first flange 1 and the second flange 2, and the first flange 1 is provided with several inserts 3 on the end faces of the second flange 2. And several slots 4, the plug 3 corresponds to a plurality of slot 4, and the slot 3 is just inserted within the slot 4, and the sidewall of the second flange 2 is provided with a threaded hole in communication with the slot 4. 5, the threaded hole 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com