Composite material extrusion die pressing device

A composite material and compression molding device technology, applied in the field of material manufacturing, can solve the problems of material waste, increased equipment cost, electricity cost and labor cost, etc., to facilitate quick switching, solve difficult cleaning, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

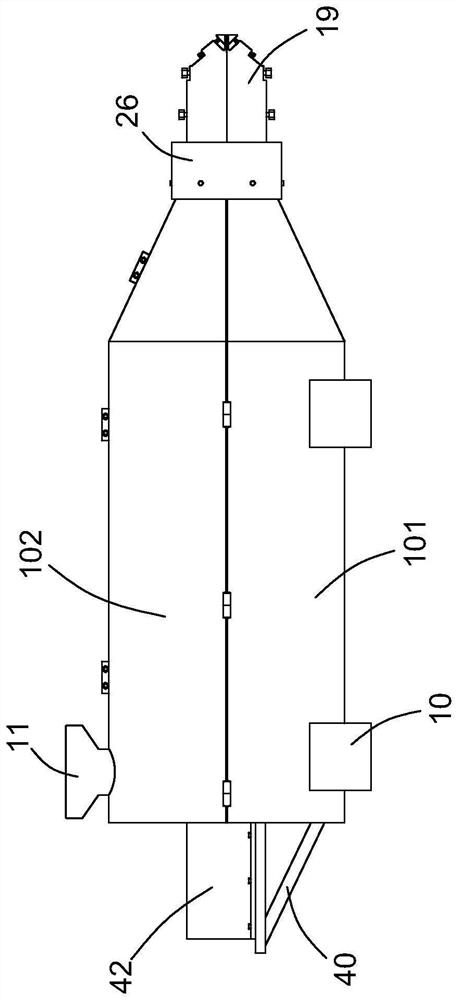

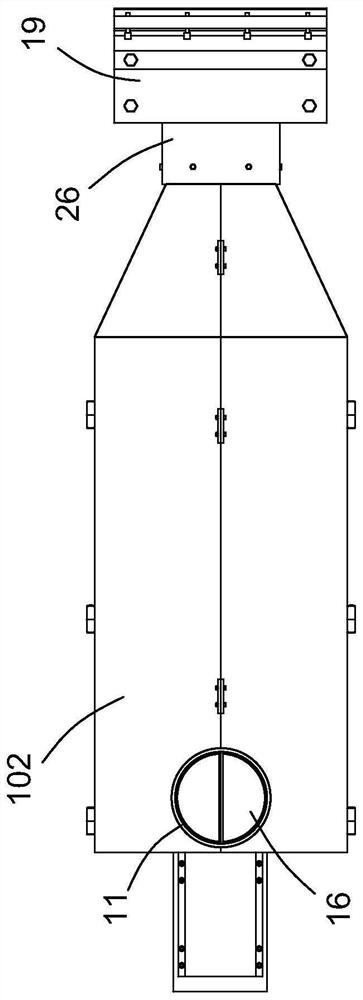

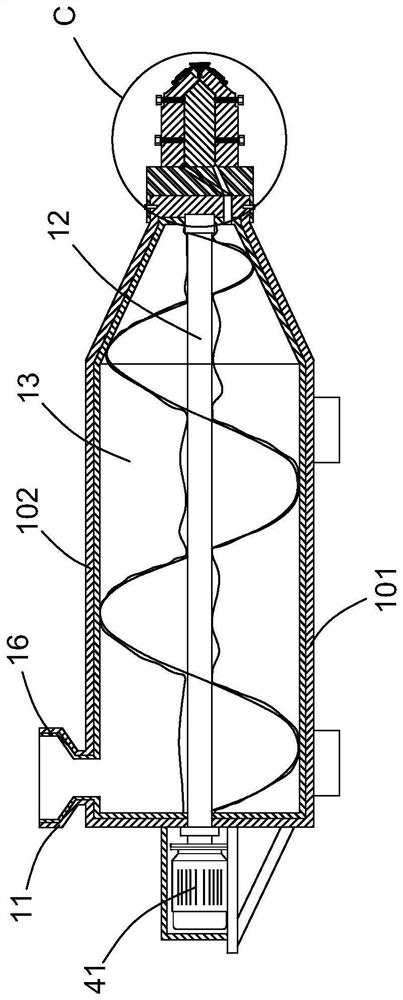

[0045] refer to Figure 1 to Figure 10 , the embodiment of the present invention discloses a composite material extrusion molding device, including a cylinder, the lower end of the cylinder is provided with a support seat 10, and the upper end of the cylinder is provided with a first lower hopper 11 communicating with the inside, so The cylinder includes a lower cylinder 101 and two upper cylinders 102, the upper cylinder 102 and the lower cylinder 101 are rotatably hinged, lugs are provided between the upper cylinders 102, and bolts pass through the lugs Locking with nuts realizes the detachable connection between the two upper cylinders 102. The first lower hopper 11 is composed of two halves, which are respectively arranged on the two upper cylinders 102. With the two upper cylinders 102 The mutually closed first lower hopper 11 is also closed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com