A rapid positioning and assembly process of an electric device

A technology for an electric device and an assembly process is applied in the field of rapid positioning and assembly process of an electric device, which can solve the problems of inconvenient assembly and high failure rate, and achieve the effects of good softening effect, convenient application and easy shaving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

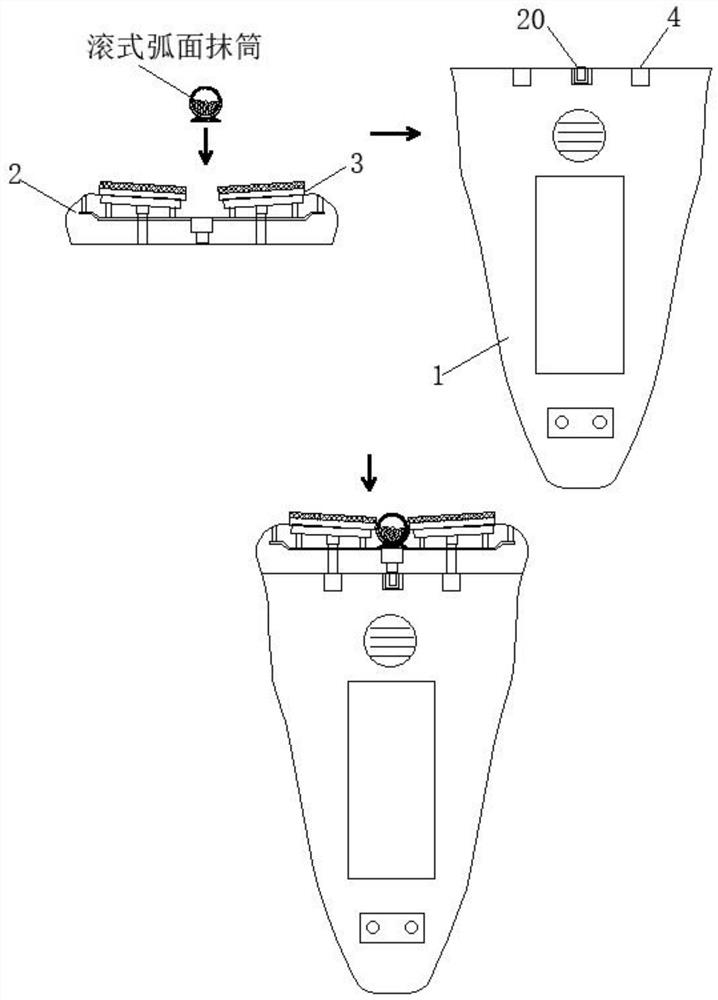

[0048] see figure 1 , a rapid positioning and assembling process of an electric device, comprising the following steps:

[0049] S1, the upper end is fixedly connected with the buffer seat 6 of the rolling cambered wiping cylinder fixedly connected to the middle of the upper end of the hair trimmer head 2;

[0050] S2, assemble the cutter 3 and the cutter net 5 to the upper end of the hair trimmer head 2 on both sides of the rolling camber wiping cylinder;

[0051] S3, assemble the detection element 20 in the middle of the upper end of the hair trimmer holding portion 1, and assemble the drive motor 4 on the upper end of the hair trimmer holding portion 1 on both sides of the detection element 20;

[0052] S4. Assemble the hair trimmer head 2 assembled with the rolling cambered trowel, the cutter 3 and the knife net 5 on the upper end of the hair trimmer holding part 1.

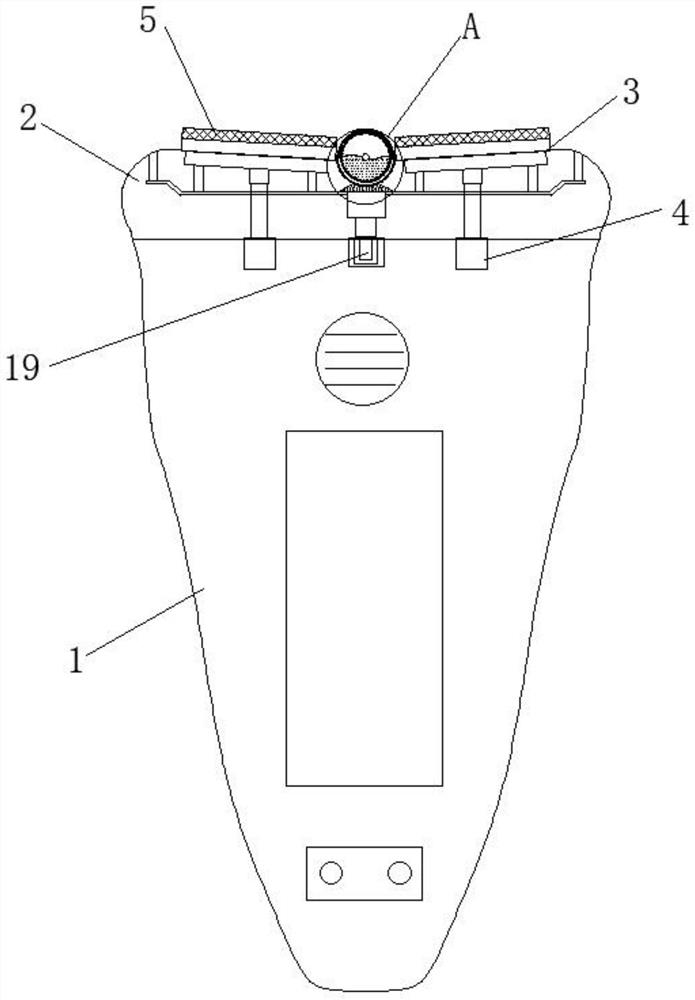

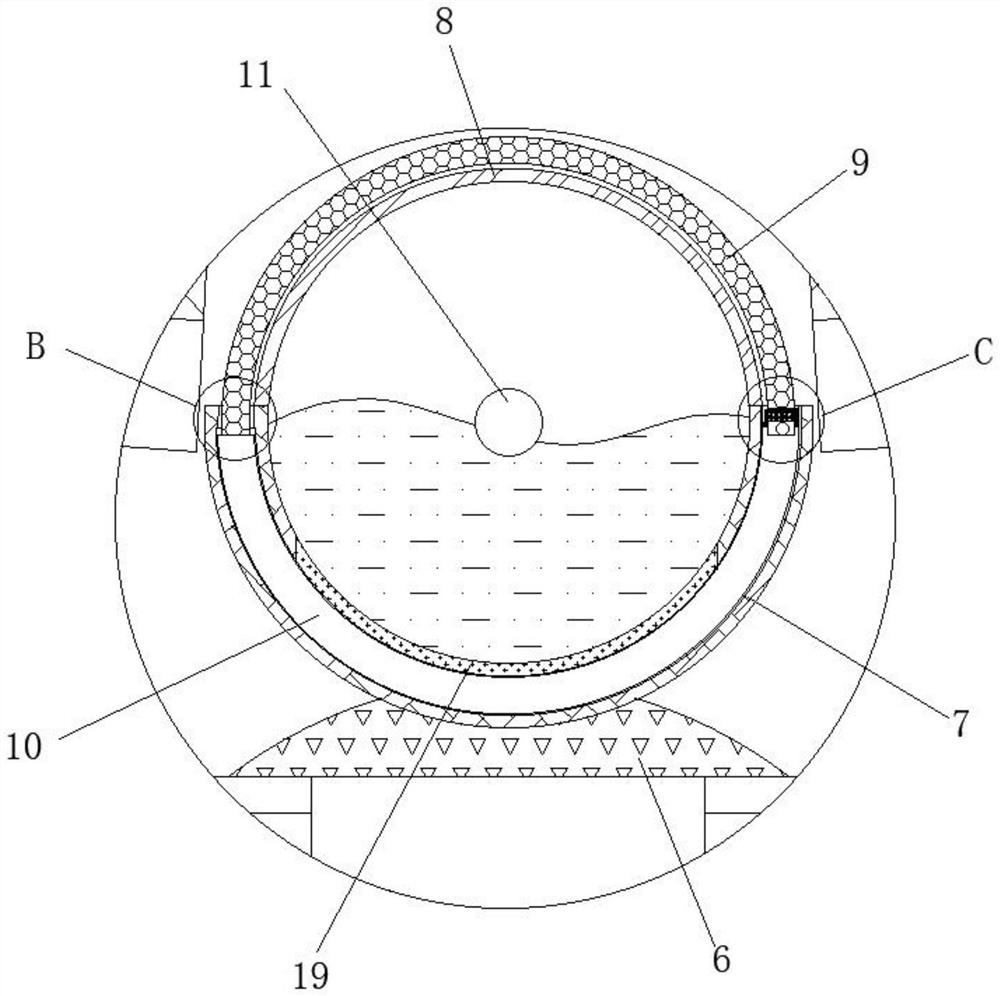

[0053] see figure 2 , image 3 , Image 6 and Figure 7 , the rolling arc surface wiper includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com