Optimization method for efficiently laying propping agents in hydraulic fracturing operation

A technology for hydraulic fracturing and optimization methods, applied in design optimization/simulation, volume measurement instruments/methods, measurement devices, etc., can solve problems such as poor effect, low efficiency, and non-standard methods, and achieve comprehensive optimization results. Effects of interference, optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Taking the 4th section of TL in Sichuan tight gas well as an example, the method of the present invention is further described.

[0098] According to the mathematical model constructed in the above steps 1 and 2, calculate and predict the hydraulic fracture geometry and proppant volume concentration distribution after hydraulic fracturing. On the basis of the above model, characterize the pumped volume fraction of proppant according to the formula in step 2

[0099] The geological and engineering condition parameters of the fourth section of gas well TL are collected and sorted out, as shown in Table 3.

[0100] Table 3. Geological and engineering parameters of the fourth section of TL in an example tight gas well

[0101]

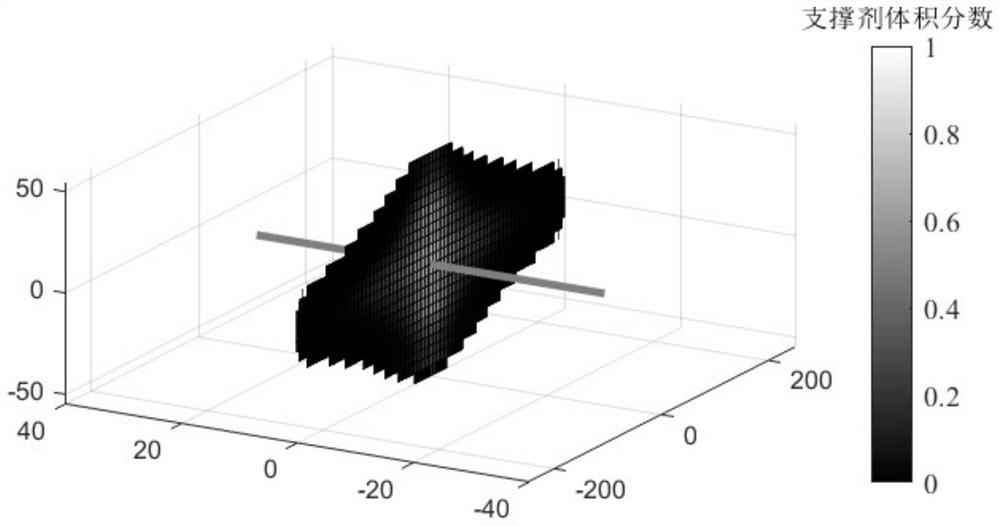

[0102] Based on L 16 The start time t of the 16 groups of pumping proppant listed in Orthogonal Table 1 c , the number n of proppant step slugs pumped and the average particle size of proppant particles a, the fracture geometry and proppant ...

Embodiment 2

[0113] Taking the fourth section of tight oil well X2 as an example, the method of the present invention is further described.

[0114] According to the mathematical model constructed in the above steps 1 and 2, calculate and predict the hydraulic fracture geometry and proppant volume concentration distribution after hydraulic fracturing. On the basis of the above model, characterize the pumped volume fraction of proppant according to the formula in step 2

[0115] The geological and engineering condition parameters of the first section of oil well X2 were collected and sorted out, as shown in Table 5.

[0116] Table 5. Geological and engineering parameters of the first section of tight oil well in Example 2

[0117]

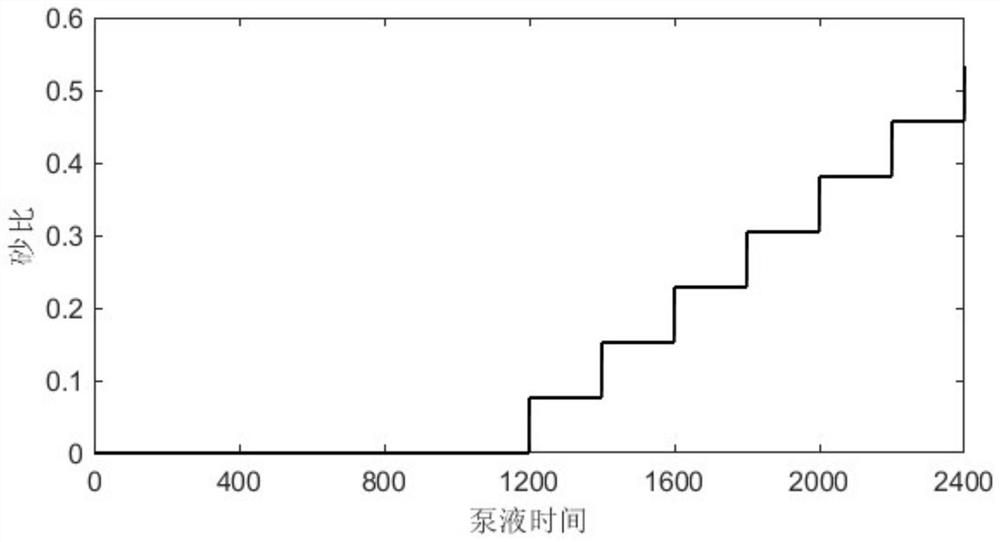

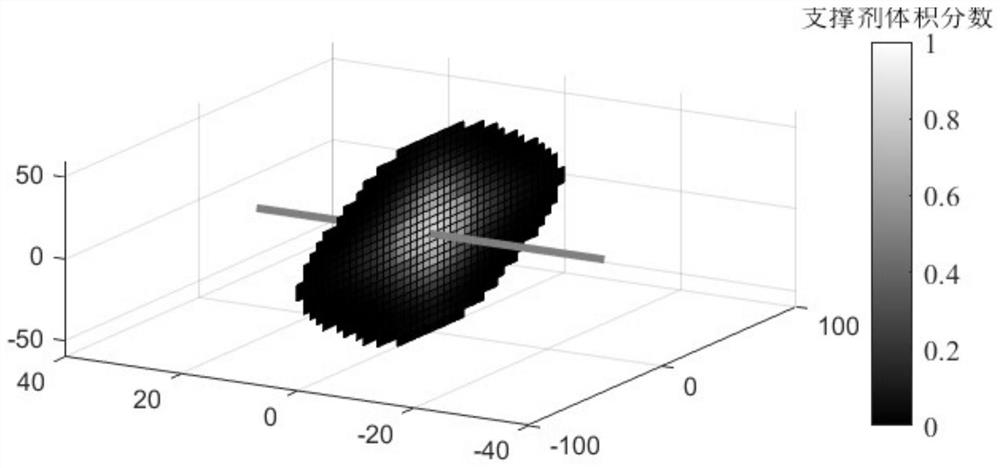

[0118] The fracturing section is planned to pump 8m 3 Quartz sand proppant, based on L 16 The start time t of the 16 groups of pumping proppant listed in Orthogonal Table 1 c , the number n of proppant step slugs pumped and the average particle size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com