Assembled experiment room for building door and window thermal insulation performance detection

A technology for thermal insulation performance, building doors and windows, applied in buildings, small buildings, building structures, etc., can solve the problems of inconvenient reassembly and disassembly, increase daily maintenance costs, increase costs, etc., and achieve fast and convenient assembly and disassembly. The effect of shifting costs and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

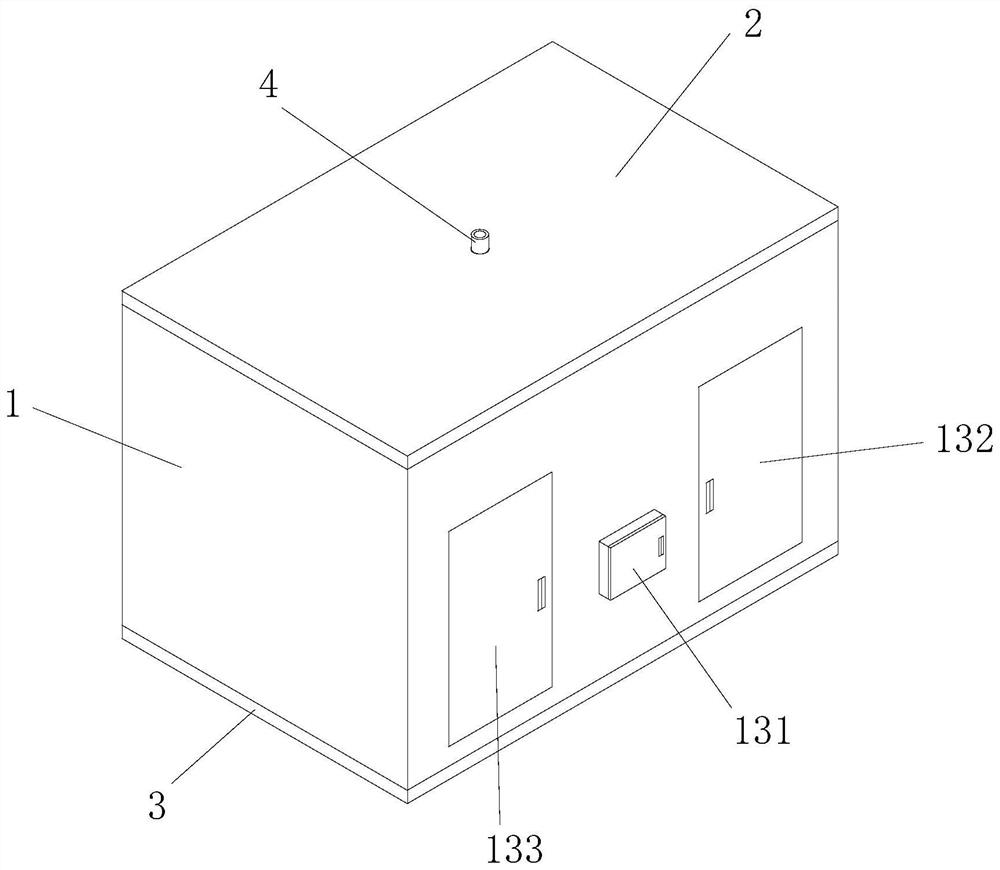

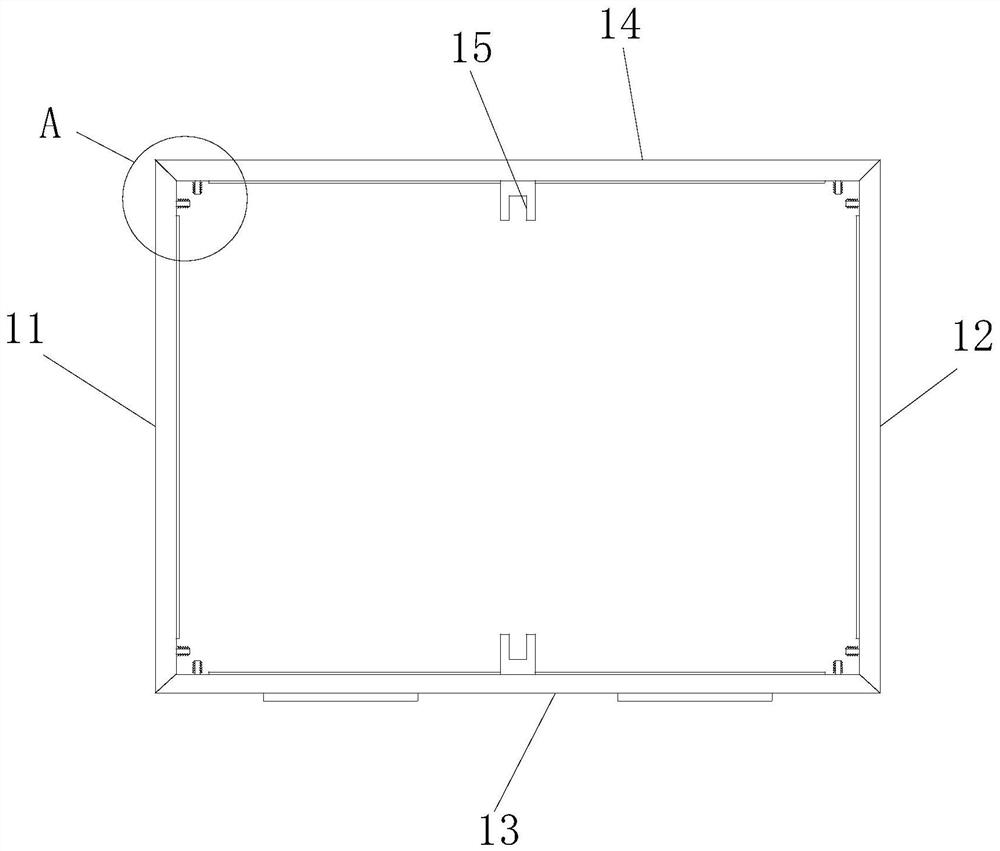

[0034] Embodiment one, please attach Figure 1-7As shown, an assembled laboratory room for testing the thermal insulation performance of building doors and windows includes a hoarding assembly 1, a top cover 2 and a bottom substrate 3, and the hoarding assembly 1 includes a first side panel 11, a second side panel 12, The front baffle 13 and the rear baffle 14, the first side panel 11 and the second side panel 12 are symmetrical, the front baffle 13 and the rear baffle 14 are symmetrical, the first side panel 11, the second side panel 12, the front baffle The panels 13 and the rear baffles 14 are sequentially spliced to form the four walls of the laboratory room, and the inner side walls of the first side panel 11, the second side panel 12, the front panel 13 and the rear panel 14 are located at the respective upper and lower ends respectively. Metal iron bars 7 are arranged in parallel, and each metal iron bar 7 is all inlaid in the plate bodies of the first side plate 11, ...

Embodiment 2

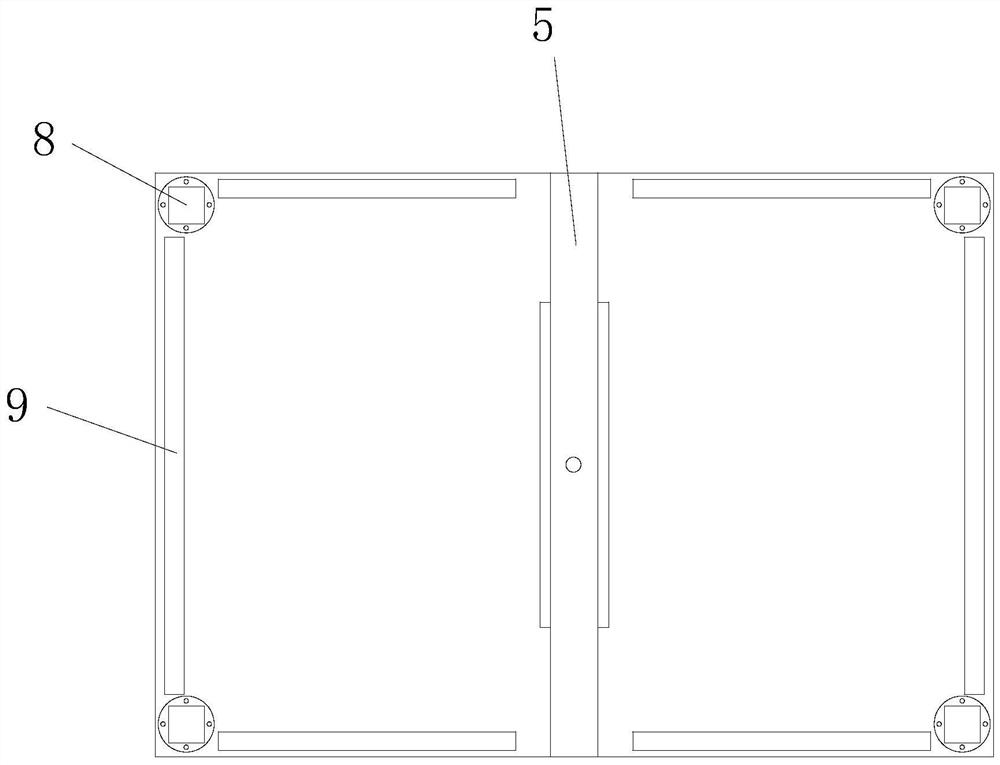

[0036] Embodiment two, please attach Figure 1-10 As shown, a partition 5 is vertically fixed at the center of the base plate 3, and the partition 5 simulates a conventional wall with a built-in heat insulation material, and the partition 5 is used to separate the hot room and the cold room in the laboratory room. To facilitate experimental testing, the top of the partition 5 is in contact with the top cover plate 2, and the center of the front baffle 13 and the rear baffle 14 are provided with a grooved stop rod 15 that fits on both sides of the partition 5. The metal iron bars 7 at the upper and lower ends of the baffle plate 13 and the rear baffle plate 14 are arranged symmetrically on both sides of the corresponding grooved limit rod 15, and the center part of the partition plate 5 is provided with a test piece installation opening 51, and the ring test piece installation opening 51 The inner wall is provided with an inflatable sealing device 54 around, and the two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com