Split installation method of converter tilting speed reducer

An installation method and reducer technology, applied in assembly machines, manufacturing converters, metal processing equipment, etc., can solve the problems of difficult installation, heavy installation and hoisting weight, etc., and achieve the effect of safety in the hoisting process and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

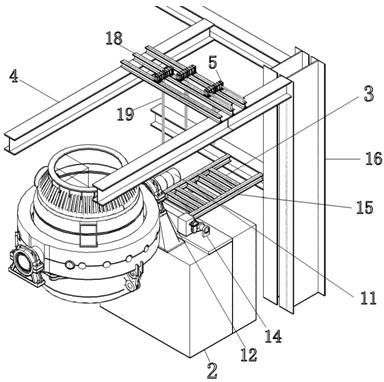

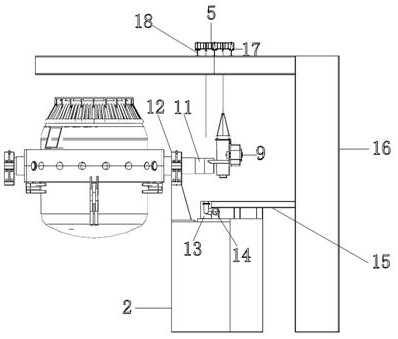

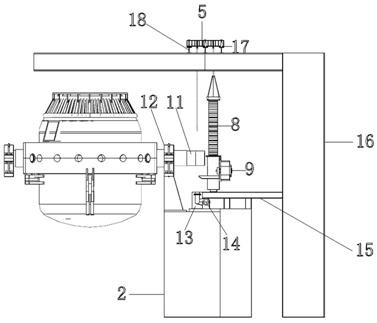

[0015] like Figure 1-7 Shown: a separate installation method for a converter tilting reducer. The specific implementation consists of the following steps:

[0016] Step 1. Disassemble the components of the converter tilting reducer 1

[0017] The converter tilting reducer 1 is decomposed into three parts: the upper box 7, the large ring gear 8, and the lower box 9. The upper box 7 and the lower box 9 are respectively composed of a primary reducer and a secondary reducer. The equipment associated with the installation of the converter tilting reducer 1 includes: the distance ring adjustment device 10, which is set on the converter support ring trunnion 11 to adjust the center distance between the converter tilting reducer 1 and the converter support ring bearing seat 12; A stop seat 13 is provided directly below the bottom of the machine 1; a connecting device is provided at the bottom of the converter tilting reducer 1 and is connected with the torsion bar 14 by connecting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com