Garbage truck rear door welding positioning tool

A technology for welding positioning tooling and garbage trucks, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting product assembly and pass rate, affecting production efficiency and manufacturing cost, and difficult to accurately locate. To achieve the effect of convenient welding operation, convenient and reliable positioning, and suitable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

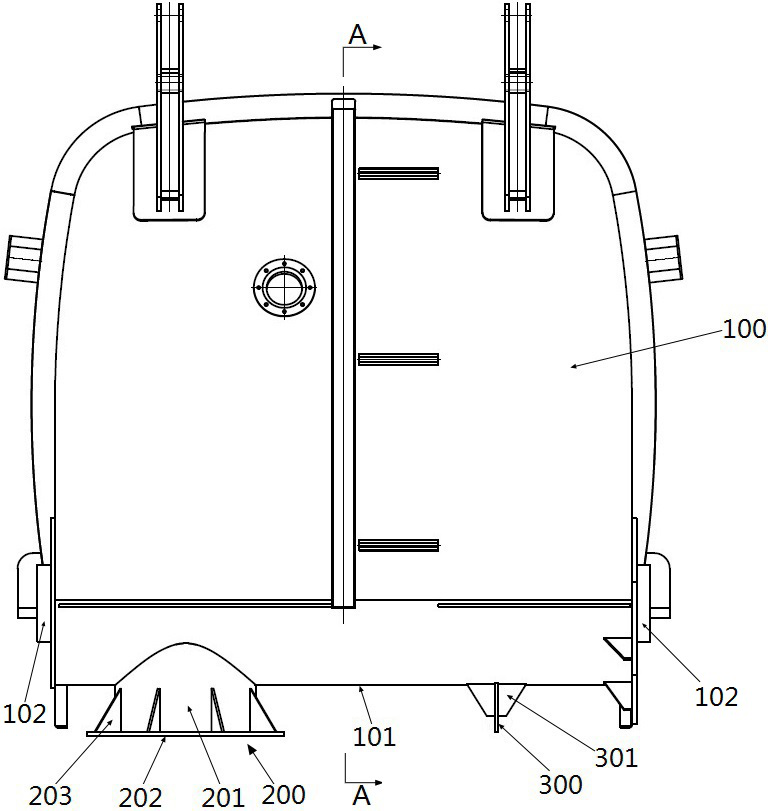

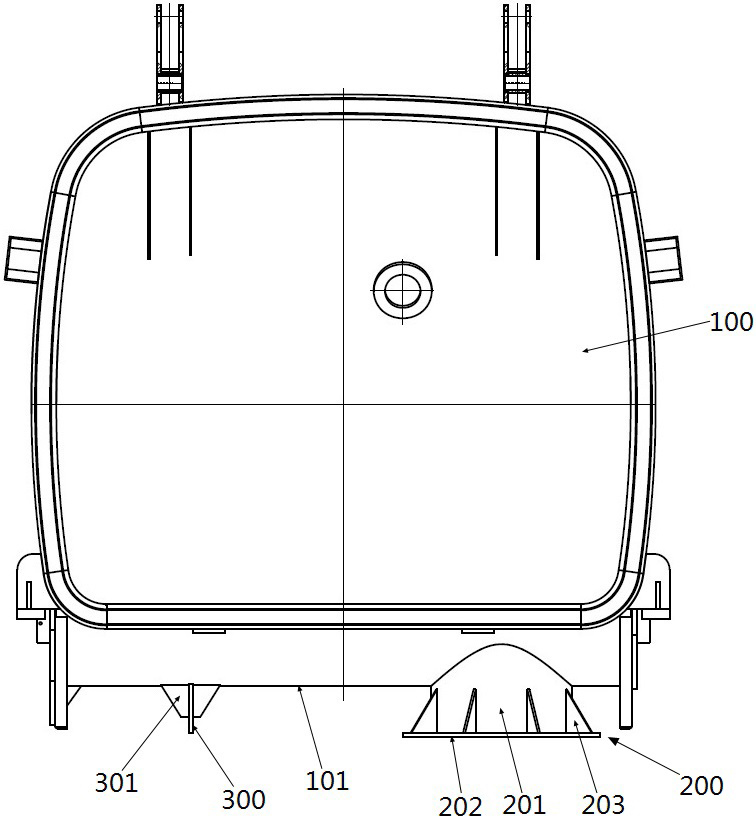

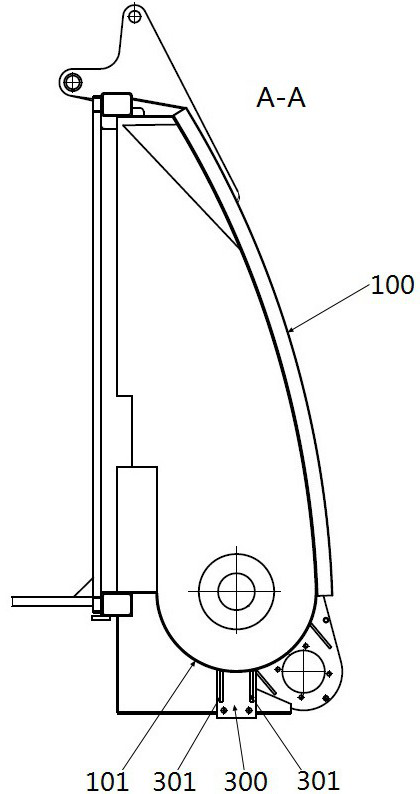

[0035] An embodiment of the welding positioning tool for the rear door of the garbage truck in the present invention is as follows: Figure 5~Figure 7 As shown, it includes a welding platform 800 , a positioning shaft 500 , a positioning frame 600 for a discharge port, and a positioning frame 700 for an oil cylinder mounting plate.

[0036] Wherein, the welding platform 800 is used for the rear door 100 of the garbage truck to be laid flat on it, and the supporting surface of the welding platform 800 actually simulates the combined surface of the garbage truck compartment and the rear door 100 .

[0037] Such as Figure 5 and Figure 6 As shown, the positioning shaft 500 runs through the auger shaft mounting plates 102 on the left and right sides of the rear door 100. Specifically, in this embodiment, the left and right positioning plates are detachably fixedly connected to the two auger shaft mounting plates 102 by bolts respectively. 401 and the right positioning plate 402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com