Pressurizing integrated forming device for auxiliary handle production

A molding device and an integrated technology, applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient production and processing of pressurized integrated molding devices, extended cooling and molding time of auxiliary handles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

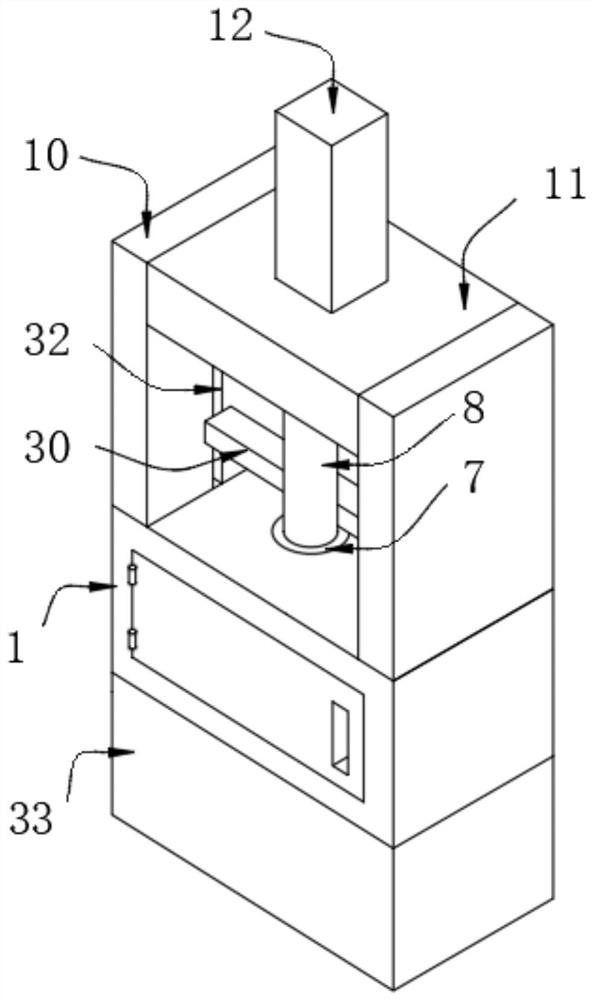

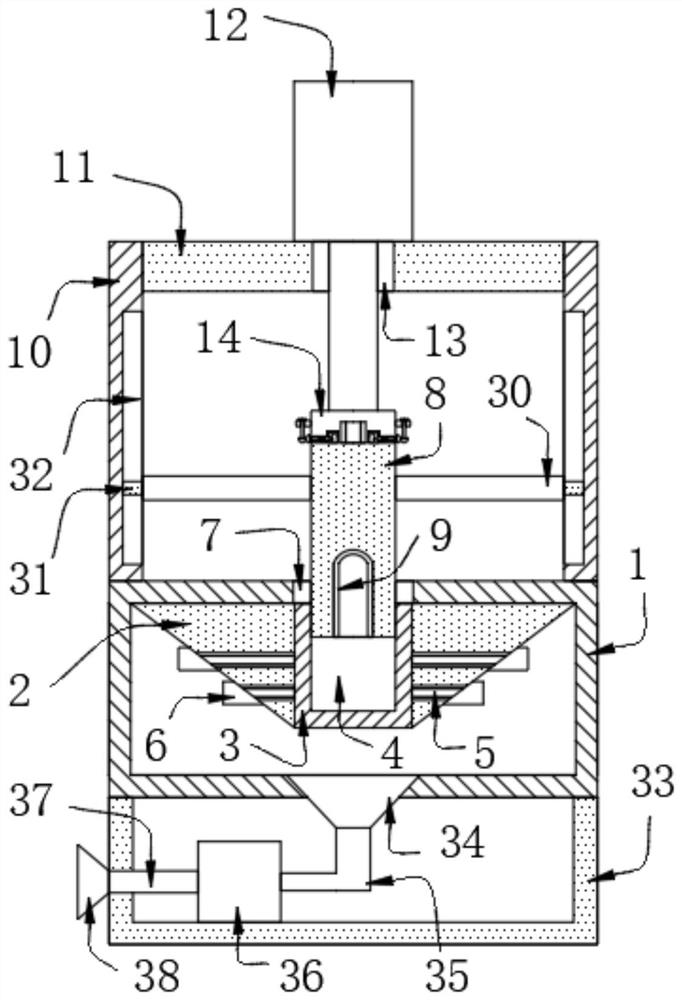

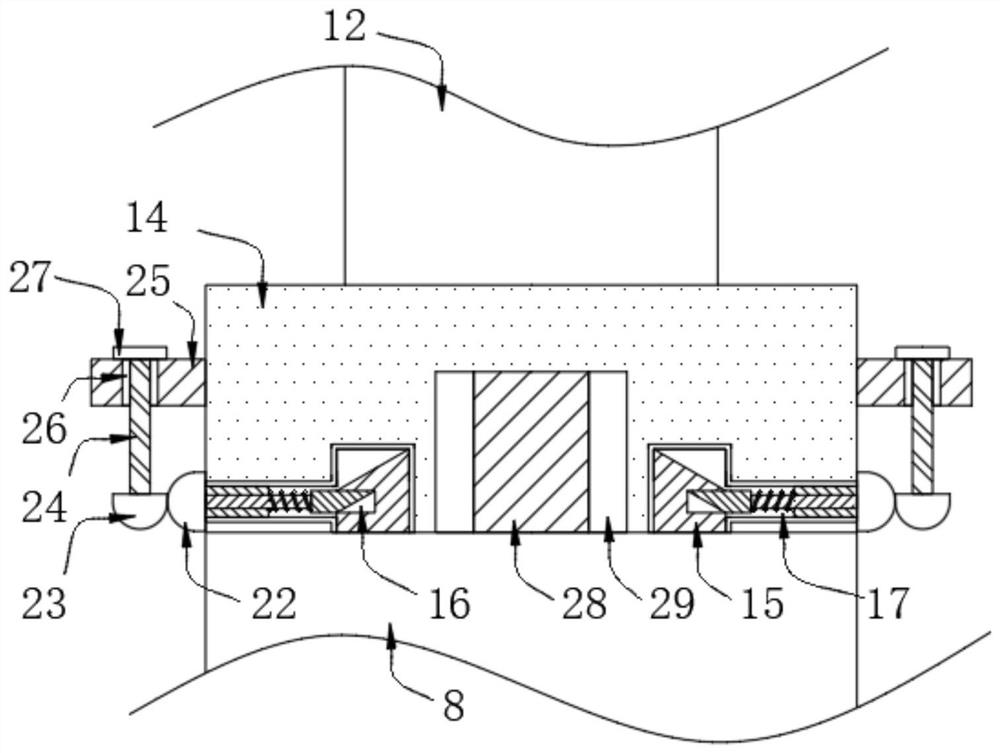

[0026] see Figure 1-4 , the present invention provides a technical solution: a pressurized integrated molding device for auxiliary handle production, including a first shell 1, the inner wall of the first shell 1 is fixedly connected with a second shell 2, the second shell 2 The inside of the lower mold base 3 is welded with a lower mold cavity 4, and the inside of the second housing 2 is evenly provided with through grooves 5 distributed equidistantly. One side of the groove 5 is evenly equipped with a semiconductor refrigeration chip 6, the top of the first housing 1 is provided with a first groove body 7, the inside of the first groove body 7 is inserted with an upper mold base 8, and the bottom of the upper mold base 8 is provided with a Upper die cavity 9, four inserts 15 are welded on the top of upper die base 8, and grooves 16 are provided on one side of the four inserts 15, and two inserts are welded symmetrically on the top of the first housing 1. A support 10, a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com