Full-automatic grinder for ore mining

A grinding machine, fully automatic technology, applied in the field of grinding machine equipment, can solve the problems of increasing the operation difficulty of the grinding machine, limited service life, reducing grinding efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

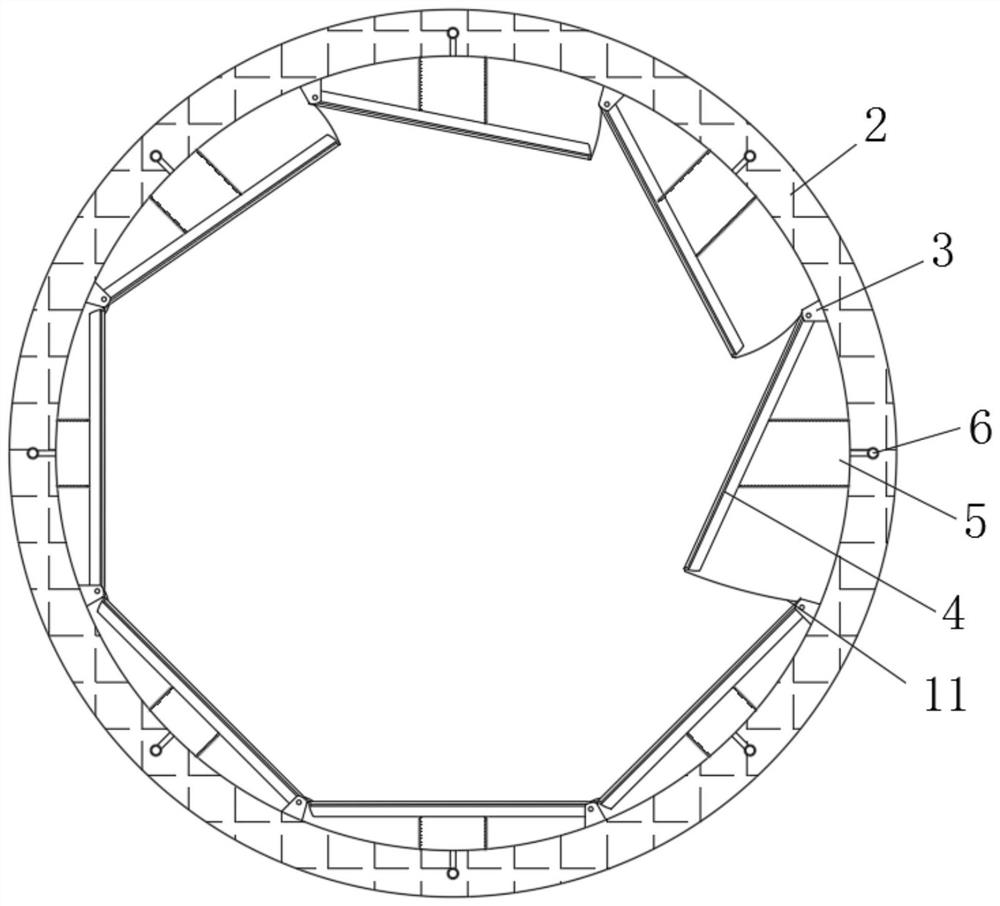

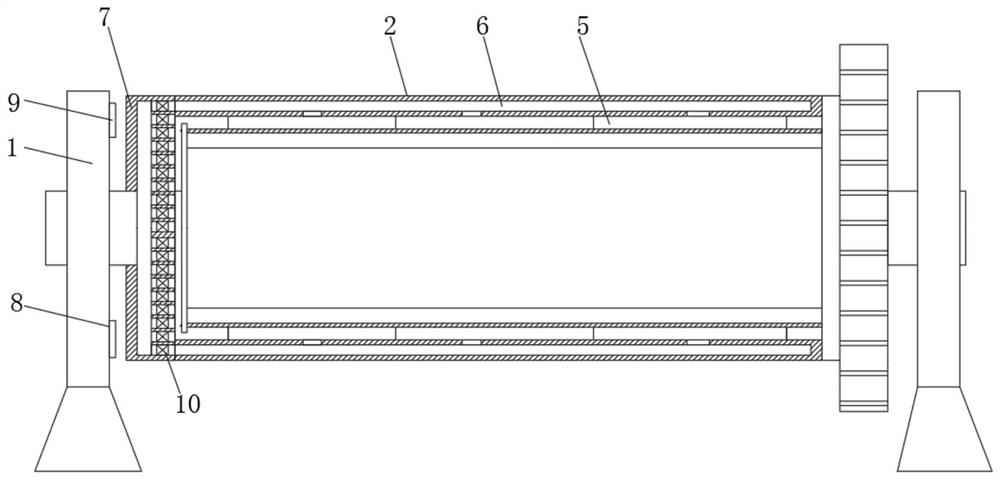

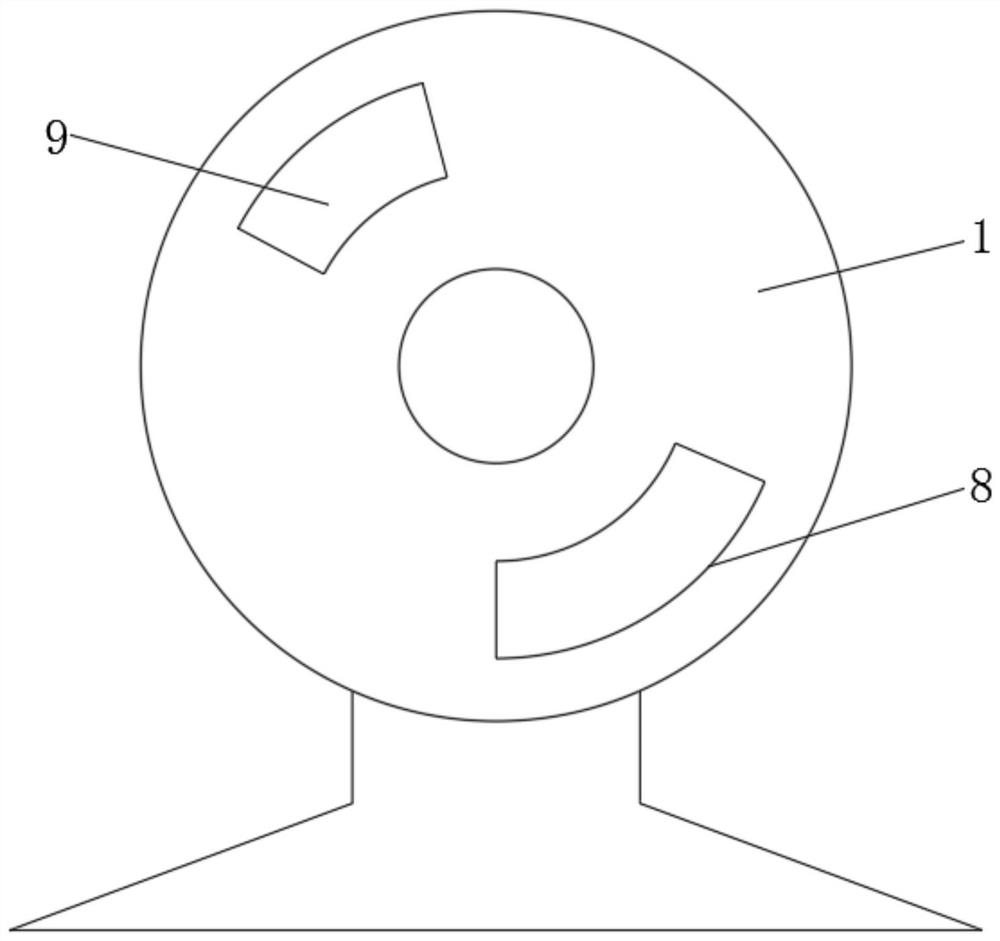

[0023] see Figure 1-2 , a fully automatic grinding machine for ore mining, including a frame 1 and a drum 2, the drum 2 is movably connected with the frame 1, and one side surface of the drum 2 is provided with a gear, which is connected to the driving gear with a motor. The inner wall of the drum 2 is movably connected with a liner 4 through the connecting block 3, and multiple sets of connecting blocks 3 and the liner 4 form a regular polygon. A driving bag 5 is arranged between the liner 4 and the inner wall of the drum 2, and the driving bag 5 is filled with Expansion plastic fluid, the drum 2 is provided with a connecting pipe 6, and the drum 2 communicates with the water distribution plate 7 located at the side end of the drum 2 through the connecting pipe 6, and each driving bag 5 is connected through the connecting pipe 6 and the water distribution plate 7, and the connecting pipe 6 and the water distribution plate 7 are provided with a control valve 10, and the frame...

Embodiment 2

[0029] The difference from Embodiment 1 is that please refer to Figure 5 , wherein, the liner 4 is a water bag filled with bulging plastic fluid, the water bag communicates with the driving bag 5, and the water bag is made of wear-resistant and pressure-resistant material, because the moment the mineral material collides with the water bag, the bulging plastic fluid It is approximately solid under force, and replaces the steel plate to realize the function of hard collision. Compared with the first embodiment, in the second embodiment, when the water bladder is pressed, the arc formed can form a support for the mineral material and the module, and at the same time increase the contact with the mineral material. Larger surface area increases friction and effectively reduces the occurrence of slippage. On the other hand, it can achieve greater compression and expansion, and has a stronger ability to push mineral materials away.

[0030] Principle of work and work flow of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com