Roundness and straightness error measuring system for deep hole part

A straightness error and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effect of convenient use, low cost and accurate error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

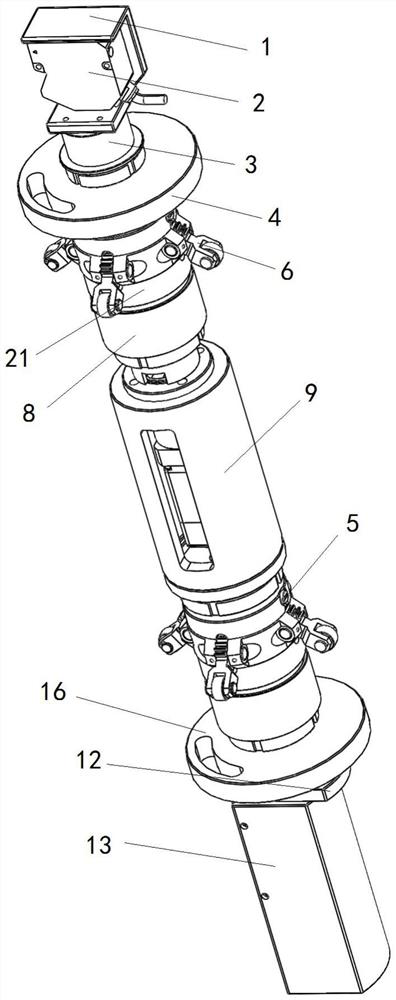

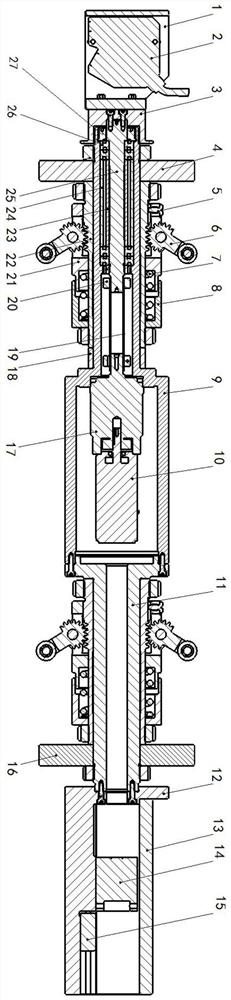

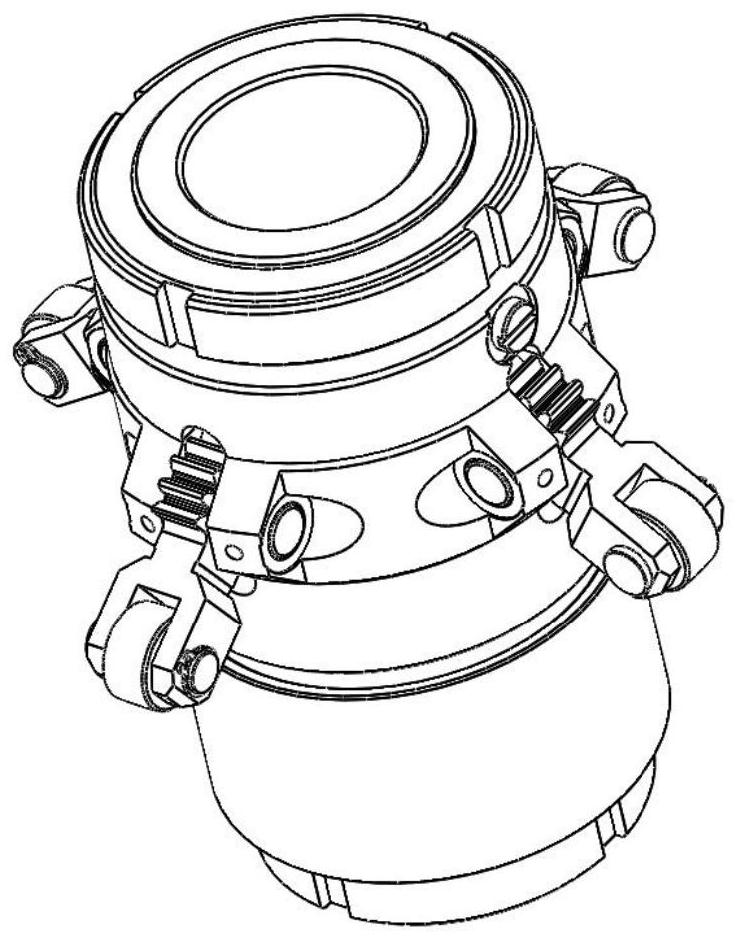

[0029] A roundness and straightness error measurement system for deep hole parts, including: a support unit, a drive unit, a measurement unit and multiple sets of centering travel units.

[0030] The support unit, the support unit includes a forward bobbin 9 and a rearward bobbin 11 arranged coaxially; the forward bobbin 9 and the rearward bobbin 11 are fixedly connected; The end is provided with a bracket 12 fixedly connected with it, and a protective cover 13 is fixedly connected with the bracket 12; a first cavity and a second cavity are arranged in the forward bobbin 9; the first cavity and the second cavity In communication, the second cavity is located at one end close to the backward bobbin 11; the rearward bobbin 11 is provided with a third cavity.

[0031] Wherein, the diameter of the second cavity is larger than the diameter of the first cavity.

[0032] The drive unit, the drive unit includes a drive device, a sleeve 19 and a drive shaft 25, the drive device is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com