Tower lifting appliance

A tower and spreader technology, which is applied to load hanging components, transportation and packaging, wind power generation, etc., can solve problems such as deformation of large-diameter towers, achieve roundness correction, stable force, and solve personal safety risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

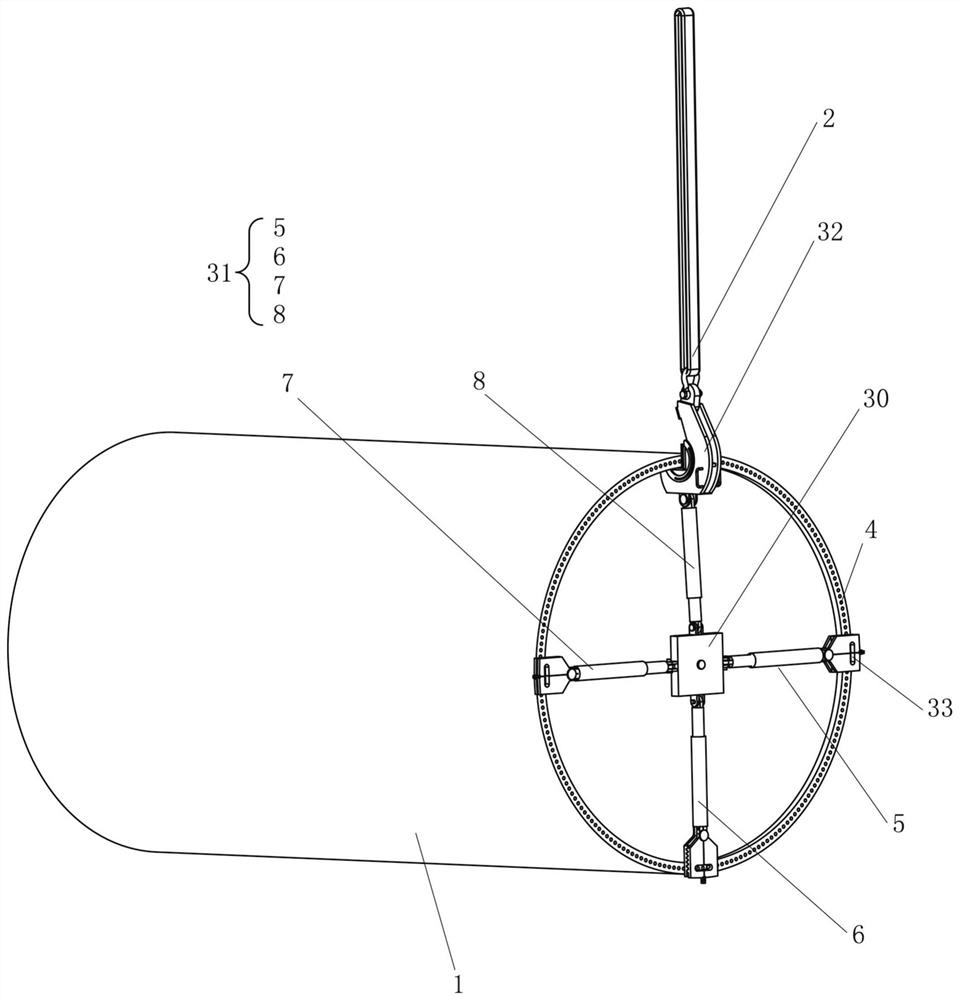

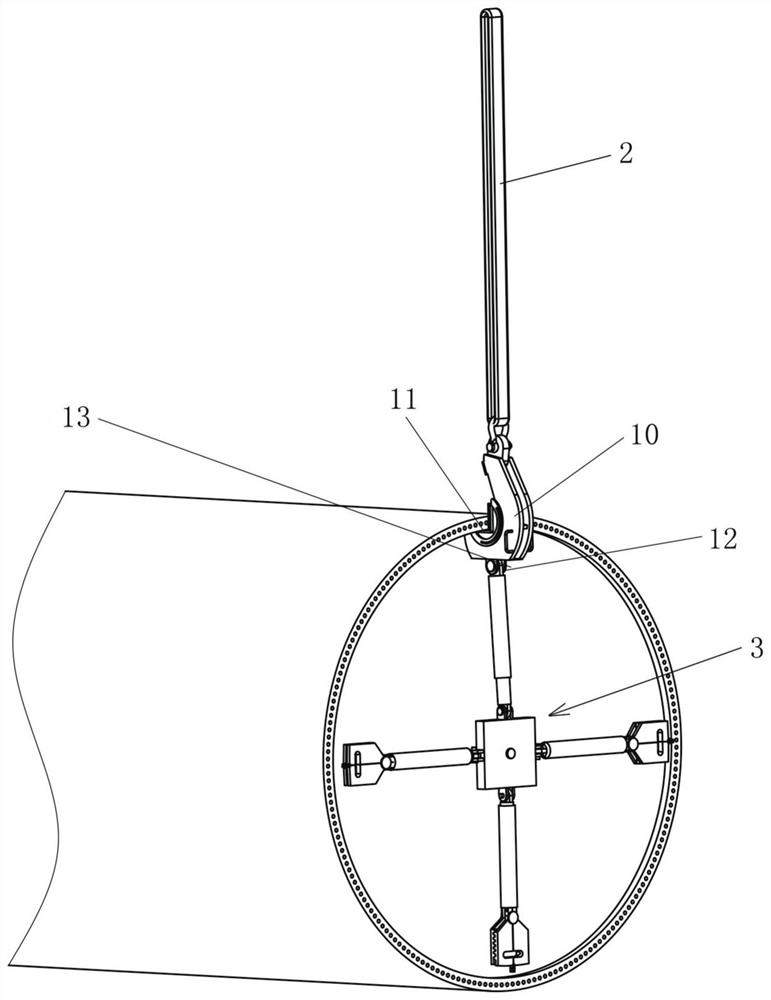

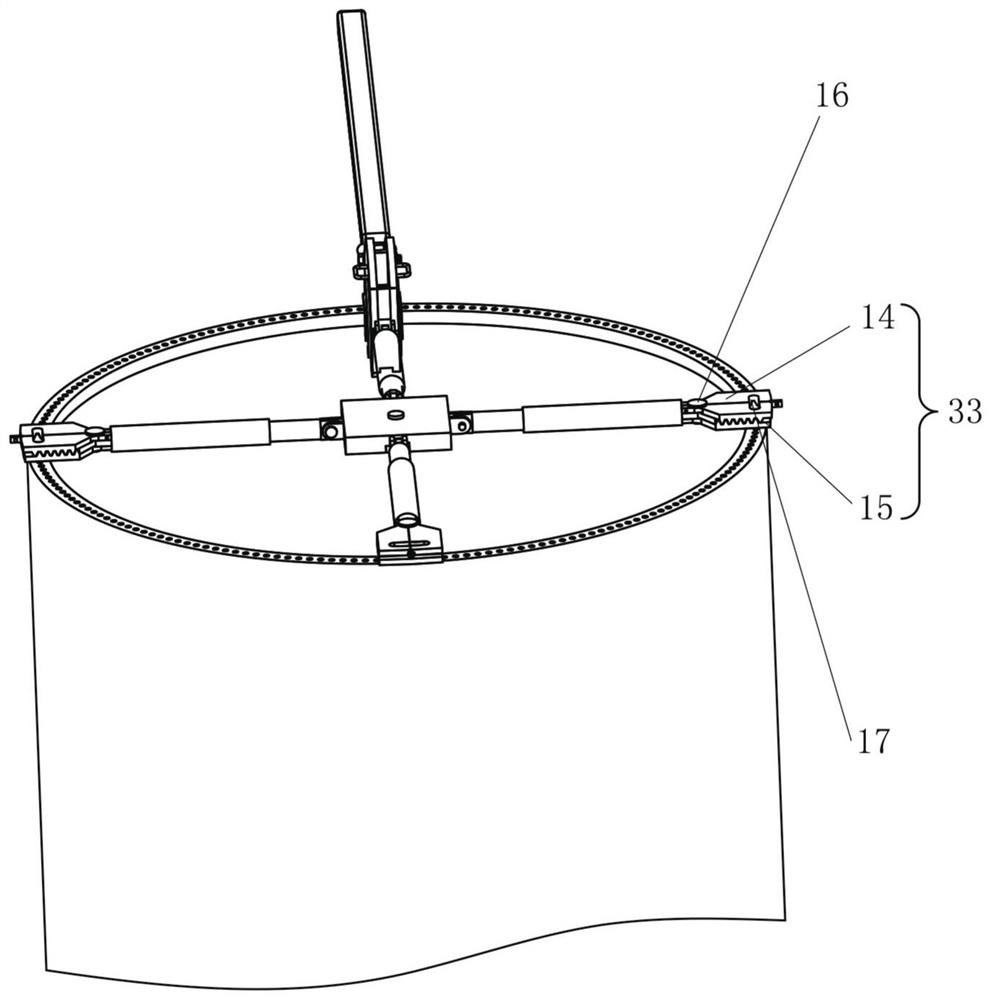

[0025] According to an exemplary embodiment of the present invention, a tower hanger 3 is provided, which includes: a connecting bracket 30; a plurality of telescopic parts 31, and the plurality of telescopic parts 31 are radially arranged at equiangular intervals, Wherein, one end of each of the multiple telescopic parts 31 is connected to the connecting bracket 30, the other end of one telescopic part 31 in the multiple telescopic parts 31 hooks the tower tube flange 4 through the hook 32, and the rest can be The other end of each of the telescoping portions 31 is fixed to the tower flange 4 .

[0026] In the drawings, the number of the retractable portions 31 is shown as four. That is, the four telescopic parts 31 are evenly arranged around the connecting bracket 30 at intervals of 90 degrees to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com