Spinning frame and joint operation method thereof

An operation method and spinning frame technology, applied to spinning machines, jointing devices, textiles and papermaking, etc., can solve problems such as waste of electric energy and roving, and achieve the effects of avoiding equipment failure, reducing production costs, and eliminating flying flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

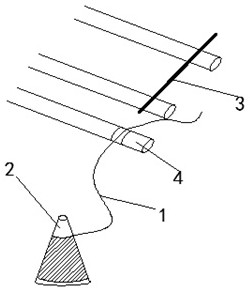

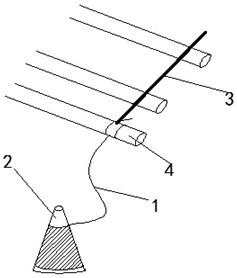

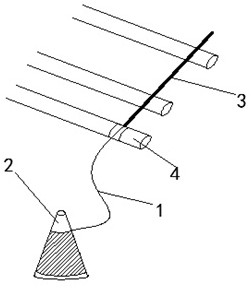

[0033] This embodiment describes a splicing operation method of a spinning frame, the spinning frame includes several rows of stations arranged side by side, each station includes a drafting mechanism for drafting the roving 3 into fiber bundles, a rotatable Spindle 2 for forming bobbins, a broken yarn detection device, the drafting mechanism includes a plurality of roller pairs including the bottom roller 4, and the splicing operation of each station can be performed without a negative pressure yarn suction device. carry out and include steps such as Figure 4 Shown:

[0034] A: Roving stop steps:

[0035] The broken yarn detection device keeps the detection of the state of the yarn 1, and when it detects that a certain station in the spinning frame has a broken yarn, the spinning frame immediately stops the roving 3 feeding roller of the station, Thereby stopping the feeding of the roving 3;

[0036] B: Yarn placement steps:

[0037] Such as figure 1 As shown, the yarn ...

Embodiment 2

[0046] This embodiment also provides a spinning frame for implementing the joint operation method described in Embodiment 1, each station of the spinning frame further includes a roving self-stopping device, and the roving self-stopping device is used to perform the step The roving stop step in A, that is, when the broken yarn detection device detects that the broken yarn occurs, the roving self-stopping device automatically stops the feeding of the roving at the station, which can effectively prevent the generation of flying flowers and avoid causing machine failure or yarn breakage. Line quality problem.

[0047] In this embodiment, each spindle 2 of the fine spinning machine is controlled by a separate motor, and when a yarn breakage occurs, the motor of the spindle 2 at the yarn breakage position controls the spindle 2 to automatically stop running. When the spinning machine station executes the yarn placement step B of the above method, after the spindle 2 stops running a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com