Preparation method of reclaimed rubber

A technology for reclaimed rubber and waste rubber powder, which is applied in the field of solid waste recycling, can solve the problems of difficult reuse of waste residues, insufficient utilization of sludge, and incomplete treatment of sludge, so as to avoid quality degradation and shorten desulfurization. Time, the effect of reducing the difficulty of chain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

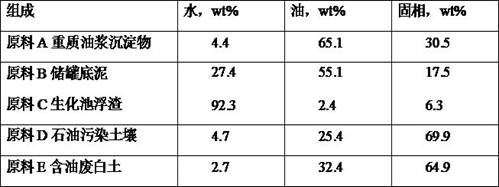

Embodiment 1

[0031] (1) The raw material composition of oily solid waste includes raw material A40wt%, raw material C35wt%, raw material D25wt%, use a plate and frame filter press for dehydration, the dehydrating agent used is polyacrylamide, and the dosage is 1.5% of the raw material mass , the moisture content after dehydration is 72.8wt%;

[0032] (2) Use No. 190 solvent oil as a pretreatment agent, and mix it with the dehydrated material in step (1) at 45°C to evenly mix, and conduct solid-liquid separation after sedimentation. The amount of the pretreatment agent is the weight of the oily solid waste raw material 2 times of

[0033] (3) Use the waste oil recovered from the sewage treatment plant as a treatment agent, mix it with the solid separated in step (2), react at 110°C for 8 hours, and then separate the solid and liquid. The amount of the treatment agent is the separated solid phase material 1 times the weight;

[0034] (4) The solid phase obtained after the solid-liquid sepa...

Embodiment 2

[0038] (1) The raw material composition of oily solid waste includes raw material A40wt%, raw material C35wt%, raw material D25wt%, use a plate and frame filter press for dehydration, the dehydrating agent used is polyacrylamide, and the dosage is 1.5% of the raw material mass , the moisture content after dehydration is 70.4wt%;

[0039] (2) Use propanol as a pretreatment agent, mix evenly with the dehydrated material in step (1) at 30°C, and conduct solid-liquid separation after sedimentation. The amount of the pretreatment agent is 6% of the weight of the oily solid waste raw material times;

[0040] (3) Diesel oil is used as a treatment agent, mixed with the solid separated in step (2), reacted at 120°C for 8.5 hours, and then separated from solid and liquid, the amount of the treatment agent used is 6 times the weight of the separated solid phase material;

[0041](4) The solid phase obtained after the solid-liquid separation in step (3) is contacted with the mixed gas an...

Embodiment 3

[0045] (1) The raw material composition of oily solid waste includes 60wt% of raw material B, 20wt% of raw material C, and 20wt% of raw material D. The plate and frame filter press is used for dehydration. The dehydrating agent used is polyacrylamide, and the dosage is 1.5% of the raw material mass , the moisture content after dehydration is 70.1wt%;

[0046] (2) Use No. 180 solvent oil as a pretreatment agent, mix it with the dehydrated material in step (1) under the condition of 50°C, and carry out solid-liquid separation after sedimentation. The amount of the pretreatment agent is the weight of the raw material of oily solid waste 2.5 times;

[0047] (3) Using kerosene as a treatment agent, mixing with the solid separated in step (2), reacting at 125°C for 12 hours, and then separating the solid and liquid, the amount of the treatment agent is 4 times the weight of the separated solid phase material;

[0048] (4) The solid phase obtained after the solid-liquid separation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com