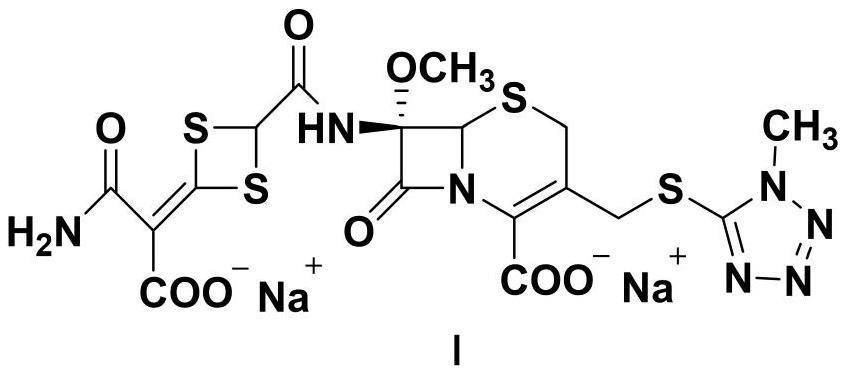

A kind of preparation method of anti-infective cephalosporin

An anti-infection and head-like technology, applied in the direction of organic chemistry, can solve the problems of unfavorable preparation production, low product purity, and low total yield, so as to promote the acetalization reaction, shorten the reaction time, and have mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

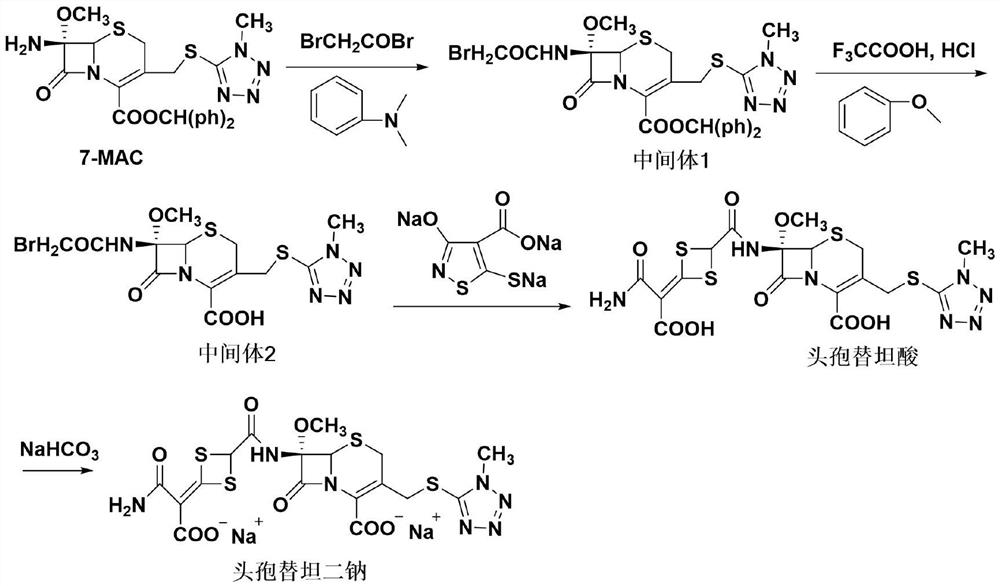

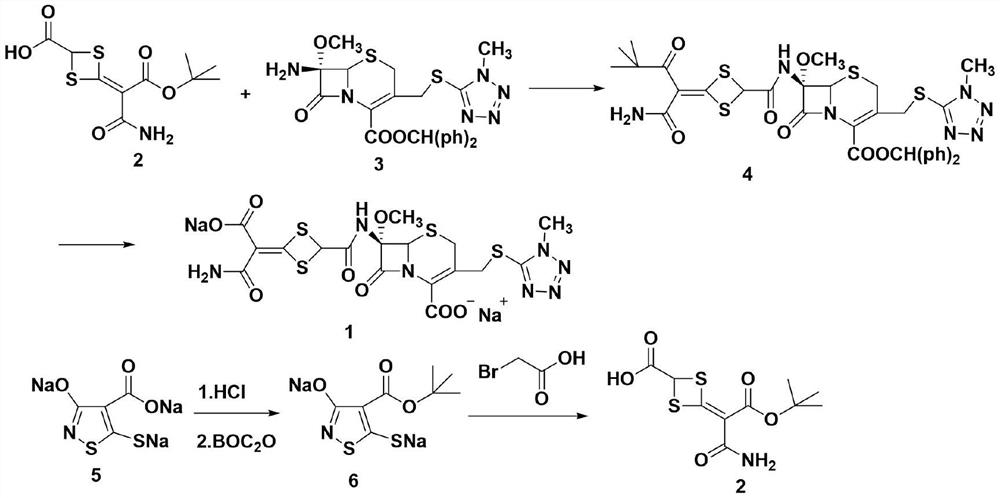

Method used

Image

Examples

Embodiment 1

[0027] 2-Oxoacetic acid hydrate (1.01g, 0.011mol, molecular weight 92.05) was dissolved in 10ml of dichloromethane, condensing agent CDI (2.59g, 0.016mol, molecular weight 162.15) was added in batches, TLC followed the reaction, and the reaction was completed Add the solution into the constant pressure funnel, add dropwise in the 40ml dichloromethane solution of compound II 7-MAC (5.25g, 0.01mol, molecular weight 524.61), the reaction temperature is 40°C, the reaction time is 10h, TLC traces the reaction is complete, wash the organic phase, dried over anhydrous sodium sulfate, filtered and concentrated to give compound III 5.73g (9.88x10 -3 mol, molecular weight 580.63), the yield is 98.8%, the HPLC purity is 99.6%, and the maximum is 0.02%.

Embodiment 2

[0029] 2-Oxoacetic acid hydrate (1.01g, 0.011mol, molecular weight 92.05) was dissolved in 10ml of dichloromethane, condensing agent DCC (3.3g, 0.016mol, molecular weight 206.33) was added in batches, TLC followed the reaction, and the reaction was completed Add the solution into the constant pressure funnel, add dropwise in the 40ml dichloromethane solution of compound II 7-MAC (5.25g, 0.01mol, molecular weight 524.61), the reaction temperature is 40°C, the reaction time is 10h, TLC traces the reaction is complete, wash the organic phase, dried over anhydrous sodium sulfate, filtered and concentrated to give compound III 5.71g (9.84x10 -3 mol, molecular weight 580.63), the yield is 98.4%, the HPLC purity is 99.5%, and the maximum is 0.02%.

Embodiment 3

[0031] 2-Oxoacetic acid hydrate (1.10g, 0.012mol, molecular weight 92.05) was dissolved in 10ml of dichloromethane, condensing agent CDI (3.24g, 0.02mol, molecular weight 162.15) was added in batches, TLC followed the reaction, and the reaction was completed Add the solution into the constant pressure funnel, add dropwise in the 40ml dichloromethane solution of compound II 7-MAC (5.25g, 0.01mol, molecular weight 524.61), the reaction temperature is 40°C, the reaction time is 10h, TLC traces the reaction is complete, wash the organic phase, dried over anhydrous sodium sulfate, filtered and concentrated to give compound III 5.72g (9.85x10 -3 mol, molecular weight 580.63), the yield is 98.5%, the HPLC purity is 99.7%, and the maximum is 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com