Inductor welding temperature control method and device

A technology of temperature control device and inductance, which is applied in the direction of high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the welding heat-affected zone cannot control the temperature stably and accurately, the welding temperature fluctuates greatly, and the welding temperature is inconsistent and other issues, to achieve the effect of reducing temperature fluctuation range, improving dynamic characteristics, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Please refer tofigure 1 Embodiments of the present invention one provides a welding temperature control device of an inductor, and the apparatus of the embodiment of the present invention includes an electrical acquisition module 1, a temperature transmitter 2, a temperature controller 3, a power regulator 4, and a transformer 5. The principle of the above modules will be described in detail below.

[0035]The main electricity acquisition module 1 is used to collect the current input voltage and calculate the power grid coefficient.

[0036]In the present embodiment, the power grid fluctuation coefficient may be a value after the acquired actual voltage divided by a standard voltage of 220V. For example: the collected voltage is 210V, the standard voltage is 220V, then the coefficient is 210 divided by 220.

[0037]The temperature transmitter 2 is used to obtain the temperature of the weld head 6 and feed back the temperature controller 3. The temperature transmitter 2 is mounted on th...

Embodiment 2

[0047]Embodiment 2 of the present invention provides an inductive welding temperature control method, and the method of the embodiment of the present invention includes the following steps:

[0048](1) Welded head pre-welding process: heating the welding head 6, uses the temperature transmitter 2 to acquire the temperature of the weld head 6, and monitor the temperature of the welding head 6, the ideal temperature and the actual temperature are performed by linear adjustment model. Adjustment, the temperature reaches the intended peak, providing a base heating temperature for the welding process;

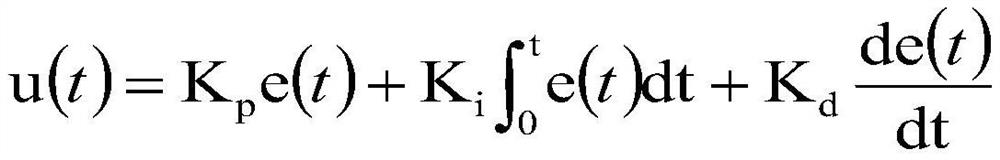

[0049]The linear adjustment model is used to compare the actual temperature of the weld head 6 with the expected peak, and if the expected peak is not reached, the temperature difference between the two actual temperatures and the actual temperature within the previous unit time, and calculates Out of the time increment in both, calculate the ratio of temperature difference and time increment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com