Tea leaf stir-frying machine

A stir-frying machine and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of tea quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

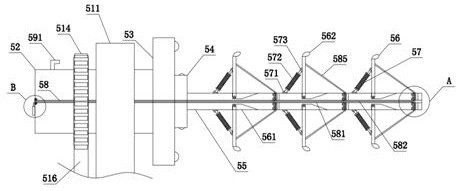

[0035] see Figure 1-5 , a tea stir frying machine, comprising a fixed frame 1, a heating furnace 2 is fixedly installed on the lower end of the fixed frame 1, a fixed sleeve 3 is fixedly installed on the upper end of the fixed frame 1, and the upper end of the fixed frame 1 on the right side A turning mechanism 4 is slidingly connected, and a stir-fry mechanism 5 is fixedly installed on the left side of the upper end of the fixed frame 1, and a moving assembly 6 is fixedly connected to the side wall of the fixed frame 1, and the right side of the lower end of the fixed frame 1 is fixedly installed. There is a receiving box 7;

[0036] The turning mechanism 4 includes a first fixed box 41, a first servo motor 42, a frying pan 43, a limit assembly 44 and a sliding assembly 45, and the first fixed box 41 is slidably connected to the upper right side of the fixed frame 1, so that The first servo motor 42 is fixedly installed inside the first fixed box 41, the output end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com