Photovoltaic module

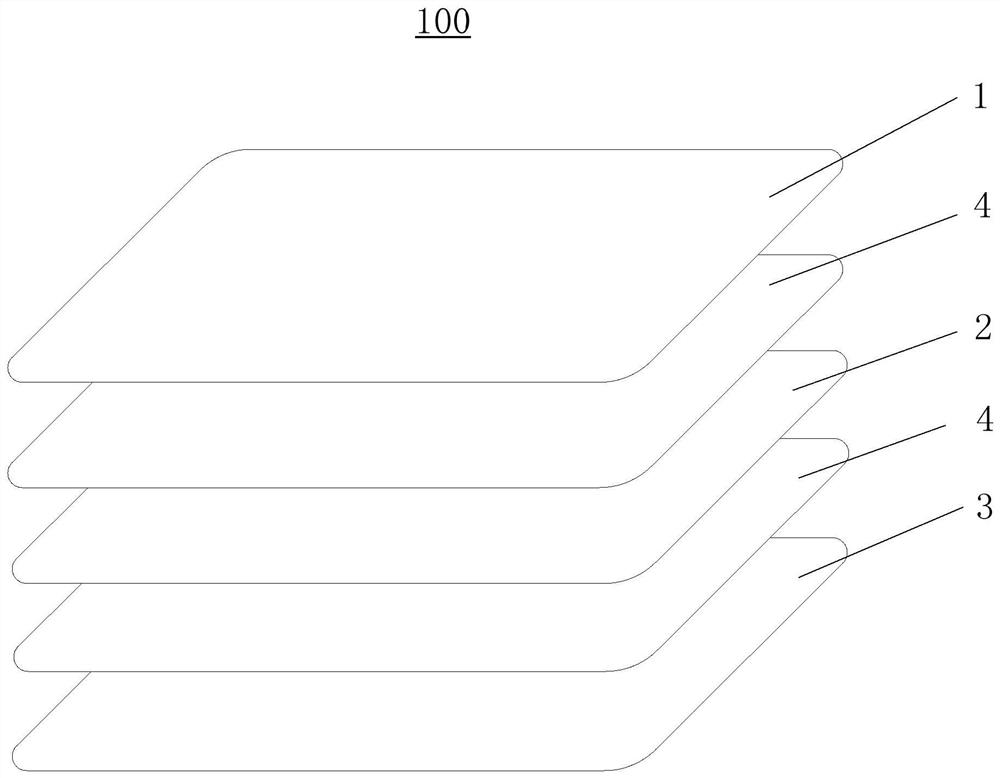

A photovoltaic module and photovoltaic cell technology, applied in the field of solar photovoltaic power generation, can solve the problems of limited UV resistance and poor weather resistance, and achieve the effects of good UV resistance, good UV resistance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

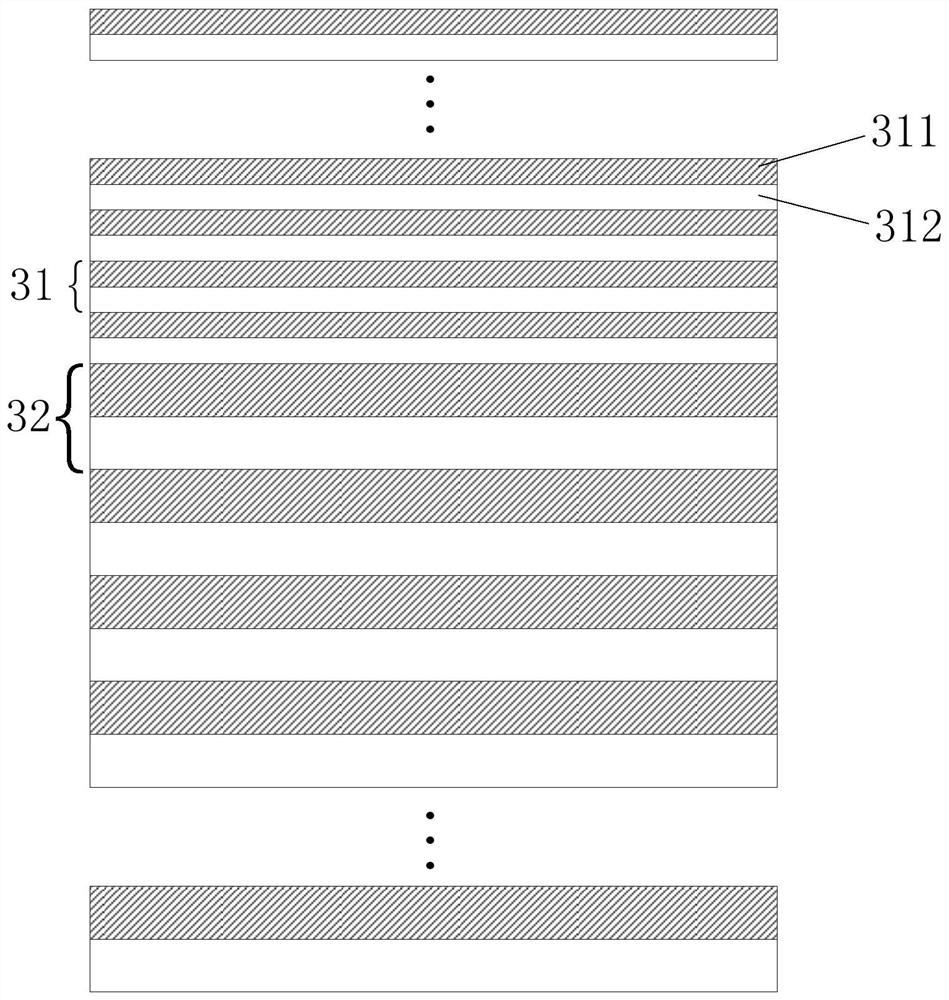

Embodiment 1

[0075]Taking PMMA and PC materials to design the first combined film structure with excellent UV resistance as an example, in order to obtain a wider emission bandwidth at a wavelength of 365nm, the first reflective film group 31 is designed for selective high reflection wavelength λ 1 For ultraviolet rays of 365nm, the second reflection film group 32 is used for selective high reflection wavelength λ 2 UV rays of 354nm. According to n × d=λ / 4, in the first reflective film group 31, the thickness of the PMMA layer is 61.2nm, and the thickness of the PC layer is 57.6nm; in the second reflective film group 32, the thickness of the PMMA layer is 59.4nm, The thickness of the PC layer was 55.8 nm.

[0076] In actual operation, set the set temperature range of the extruder to 280°C, 275°C, 270°C, 265°C, 260°C, set the temperature of the multiplier and the extrusion die to 260°C and 220°C respectively, and cast the cooling roll The set temperature is 120°C. Firstly, 128 sets of re...

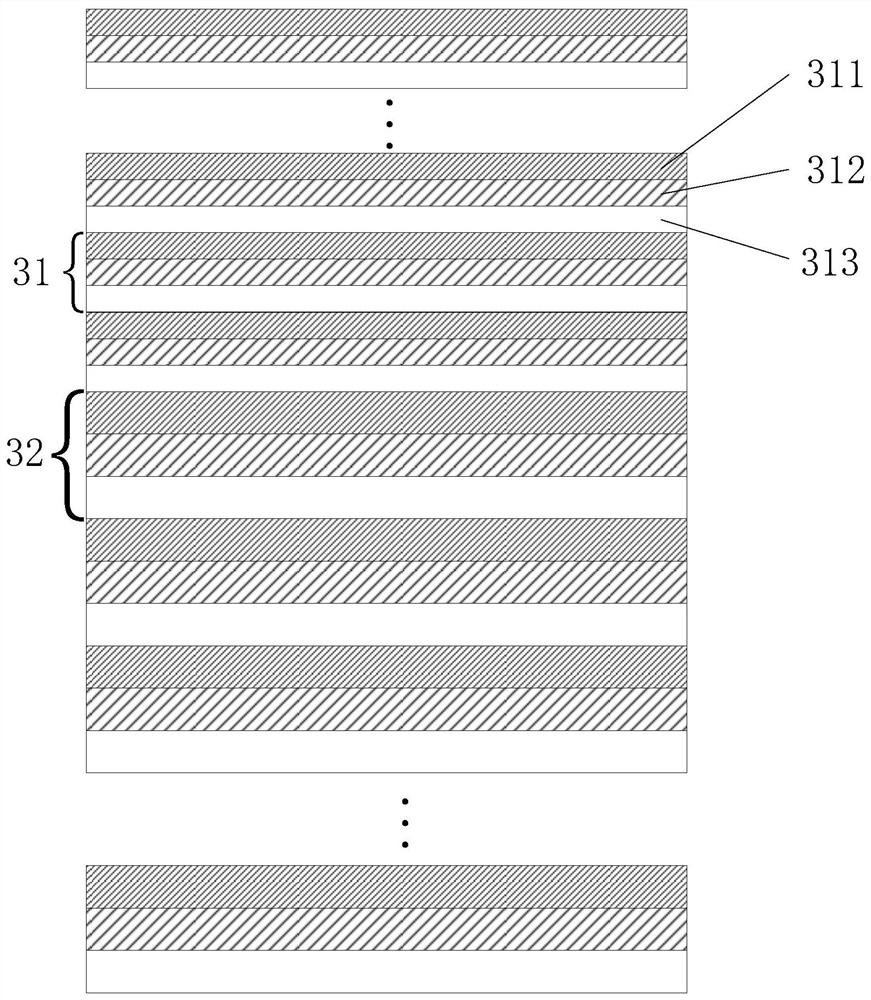

Embodiment 2

[0079] Taking PMMA and PC materials to design the first combined film structure with excellent UV resistance as an example, the first reflective film group 31 is designed for selective high reflection wavelength λ 1 For ultraviolet rays of 365nm, the second reflection film group 32 is used for selective high reflection wavelength λ 2 UV rays of 1100nm. According to n × d=λ / 4, in the first reflective film group 31, the thickness of the PMMA layer is 61.2nm, and the thickness of the PC layer is 57.6nm; in the second reflective film group 32, the thickness of the PMMA layer is 184.6nm, The thickness of the PC layer was 173.5 nm.

[0080] In actual operation, set the set temperature range of the extruder to 280°C, 275°C, 270°C, 265°C, 260°C, set the temperature of the multiplier and the extrusion die to 260°C and 220°C respectively, and cast the cooling roll The set temperature is 120°C. Firstly, 128 groups of reflective film groups with equal thickness are obtained by stacking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com