Pantograph carbon contact strip abrasion detection system

A pantograph carbon slide and detection system technology, applied in the direction of instruments, calculations, computer components, etc., can solve the problems of inability to realize online monitoring, high cost, and great influence on measurement accuracy, and achieve simple, efficient, and accurate measurement methods high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

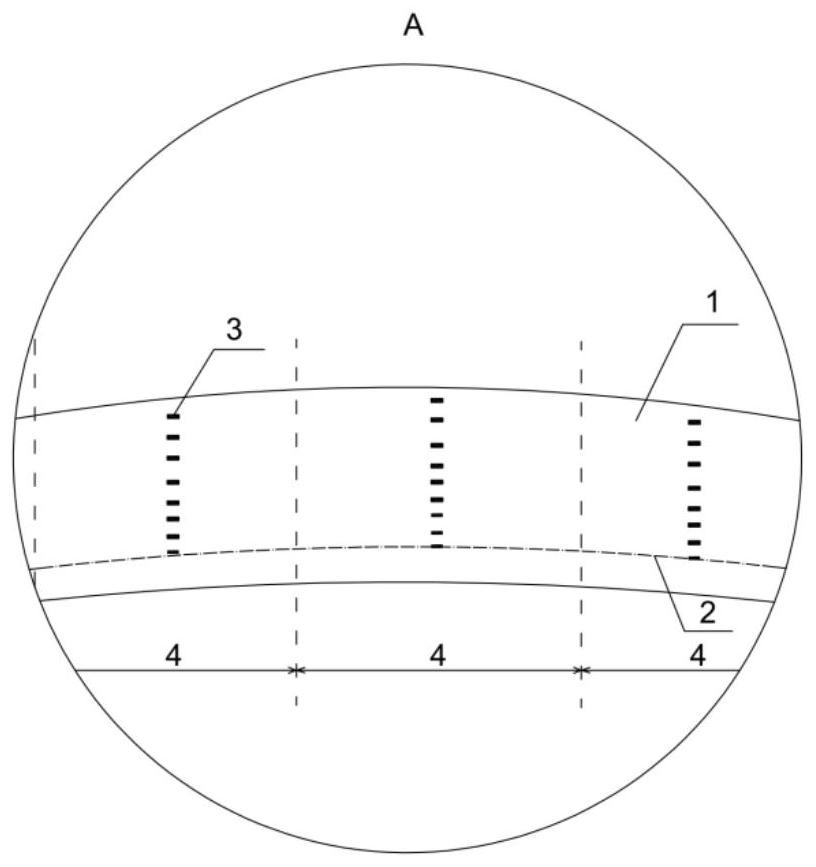

[0035] A pantograph carbon sliding plate wear detection system, including a data acquisition unit, a data processing unit and a control center, the data acquisition unit includes a radio frequency tag and a radio frequency reader, the control center controls the work of the radio frequency reader, and the control center is in After each lowering of the bow, when the temperature of the pantograph drops to room temperature, the read information is sent to the RF reader;

[0036] The radio frequency tags are arranged in different areas and at different depths of the wear area of the carbon slide plate of the pantograph. When wear occurs, the radio frequency tags in the corresponding wear area will be damaged or dropped;

[0037] The radio frequency reader is installed on the roof of the train. When the radio frequency reader receives the reading information sent by the control center, it sends an inquiry signal to the radio frequency tag and reads the undamaged radio frequency r...

Embodiment 2

[0043] A pantograph carbon sliding plate wear detection system, including a data acquisition unit, a data processing unit and a control center, the data acquisition unit includes a radio frequency tag and a radio frequency reader, the control center controls the work of the radio frequency reader, and the control center is in After each lowering of the bow, when the temperature of the pantograph drops to room temperature, the read information is sent to the RF reader;

[0044] The radio frequency tags are arranged in different areas and at different depths of the wear area of the carbon slide plate of the pantograph. When wear occurs, the radio frequency tags in the corresponding wear area will be damaged or dropped;

[0045] The radio frequency reader is installed on the roof of the train. When the radio frequency reader receives the reading information sent by the control center, it sends an inquiry signal to the radio frequency tag and reads the undamaged radio frequency r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com