Oil outlet filter screen differential pressure high pressure control calibration device

A calibration device and filter screen technology, which is applied to measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of unqualified filtering effect, unqualified oil quality of EH oil, failure to calibrate, waste of spare parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

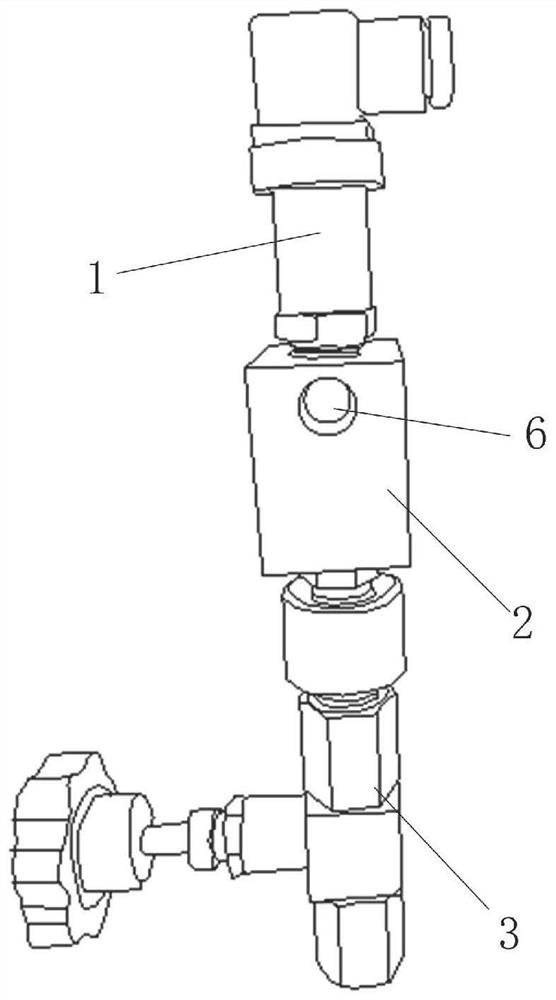

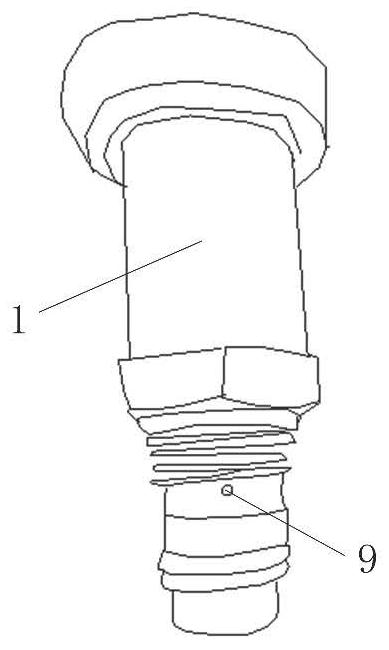

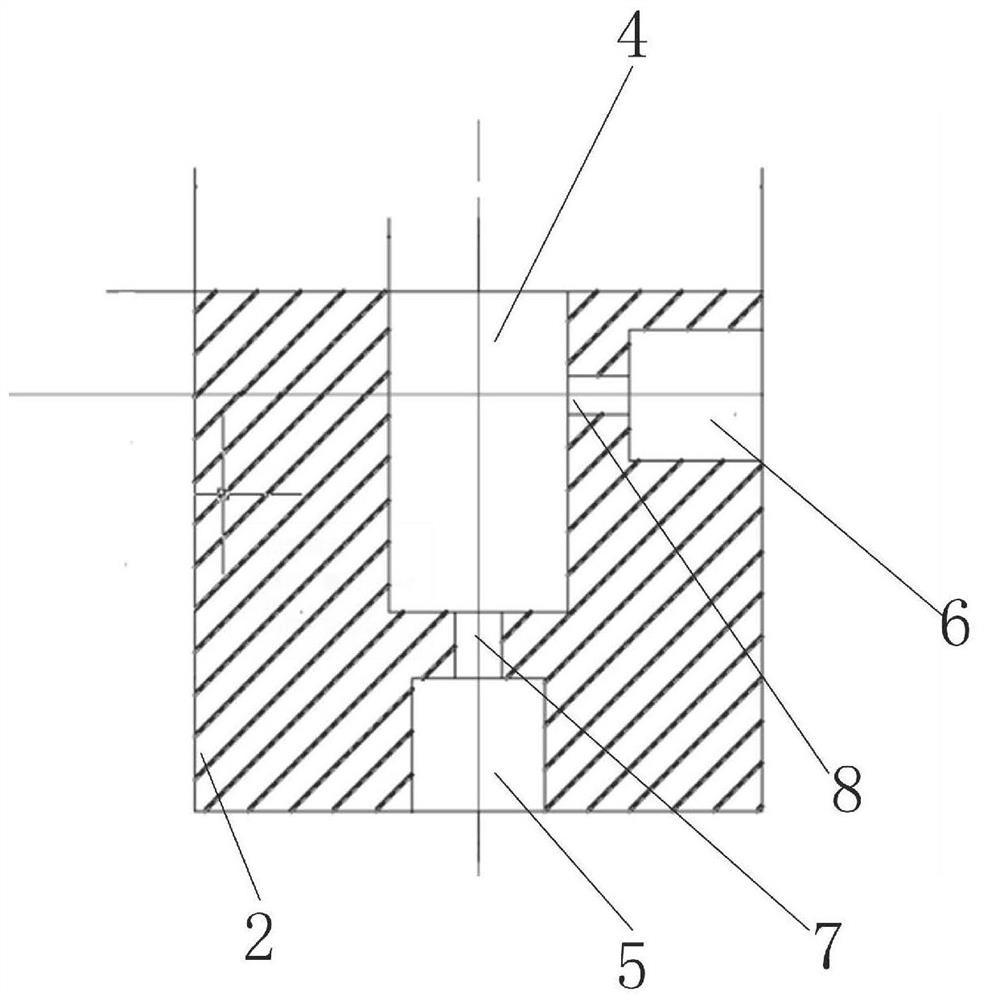

[0021] See Figure 1-Figure 5 , the embodiment of the present invention provides an oil outlet filter screen differential pressure high pressure control verification device 2, comprising: a differential pressure switch 1, the differential pressure switch 1 is used to detect the oil pressure at the oil outlet of the oil pipe 3; A verification device 2 is provided at the outlet of the differential pressure switch 1, the inlet of the verification device 2 communicates with the outlet of the differential pressure switch 1, and the outlet of the verification device 2 communicates with the oil outlet pipe 3 ; The verification device 2 is a block structure with first threaded hole 4 and second threaded hole 5 respectively at both ends, and the side wall of the block structure is provided with the first threaded hole 4 A connected third threaded hole 6, a first passage 7 is arranged between the first threaded hole 4 and the second threaded hole 5, and one end of the first passage 7 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com