Encoder coded disc eccentricity detection equipment and eccentricity adjusting method

A technology of eccentricity detection and eccentricity adjustment, which is applied in the field of encoder assembly and adjustment, and can solve problems such as misalignment of rotating shafts and angular position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

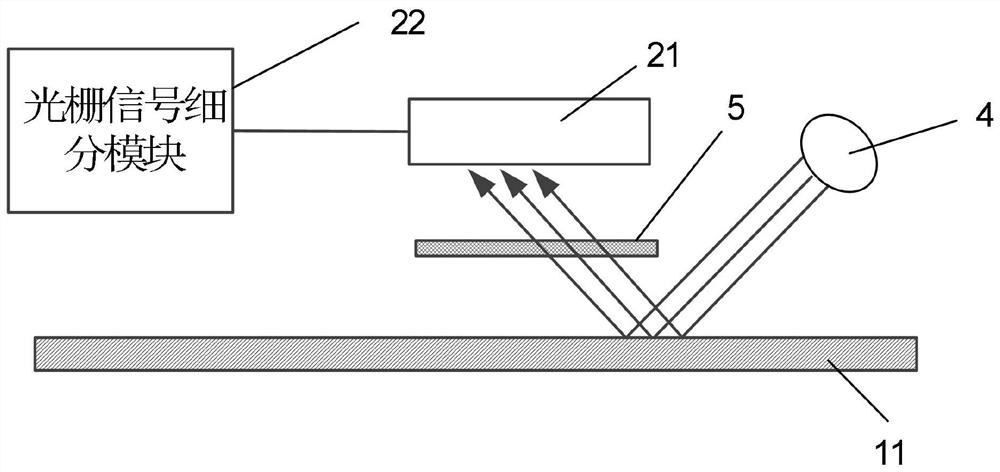

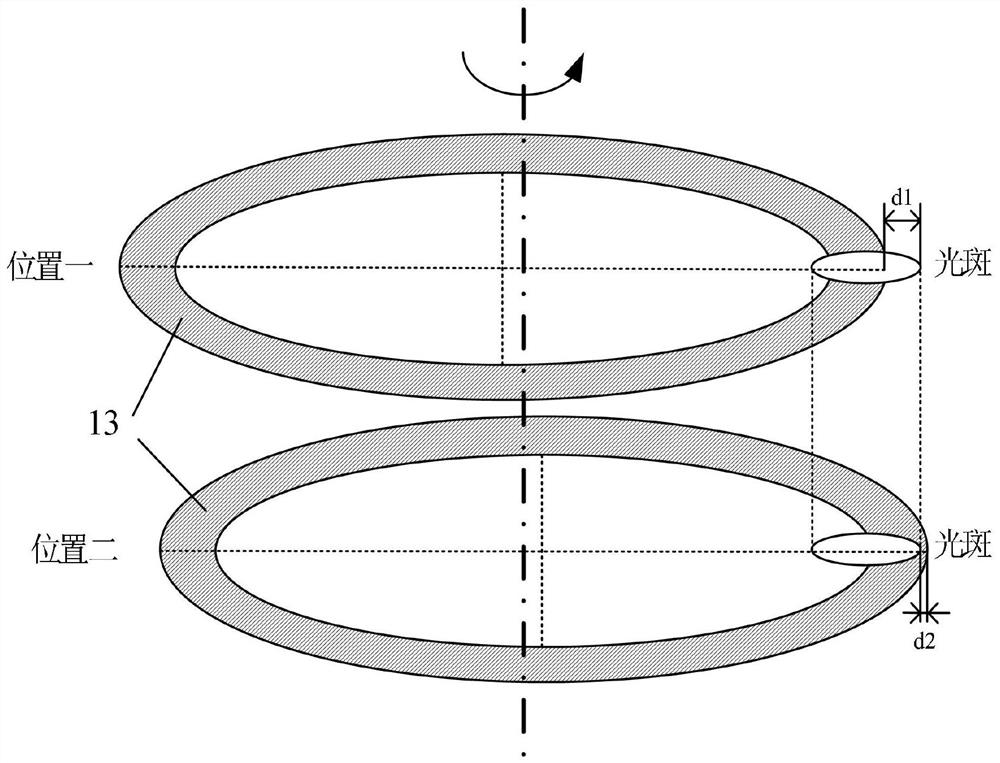

[0038] At present, the conventional detection and adjustment method for the eccentricity error of the rotary encoder is carried out through a microscope. The field of view of the microscope is circular, and generally there will be a cross-shaped baseline at the center of the circular field of view. When using a microscope to adjust the relative offset between the rotary shaft and the center of the code disc in the rotary encoder, the microscope can be directly above the rotary encoder to face the code disc, and the center of the cross-shaped baseline of the circular field of view is aligned with the rotary shaft. The offset between the base circle of the circular field of view and the circular code track on the code wheel can determine the offset of the code wheel relative to the rotating shaft, and thus adjust the relative eccentricity between the code wheel and the rotating shaft . Although this adjustment method can realize the eccentric adjustment between the code disc an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com