Intelligent defrosting method for refrigerating system based on evaporation temperature difference and refrigerating system

A refrigeration system and evaporation temperature technology, applied in defrosting, refrigerators, refrigeration components, etc., can solve the problems of large amount of frost in the evaporator, affecting the refrigeration effect, and the decline in refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

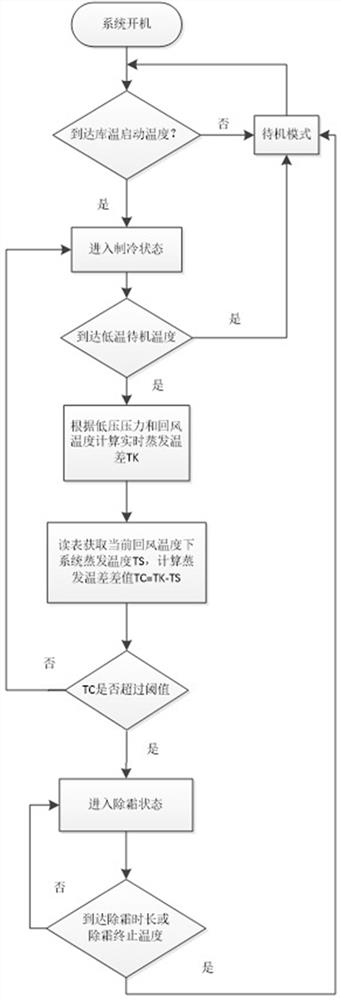

[0024] A method for intelligent defrosting of refrigeration systems based on evaporation temperature difference, such as figure 1 shown, including the following steps:

[0025] 1) After the refrigeration system is turned on, it is judged according to the current storage temperature. When the storage temperature is higher than the start-up temperature set by the refrigeration system, it will enter the cooling state, otherwise it will enter the standby state;

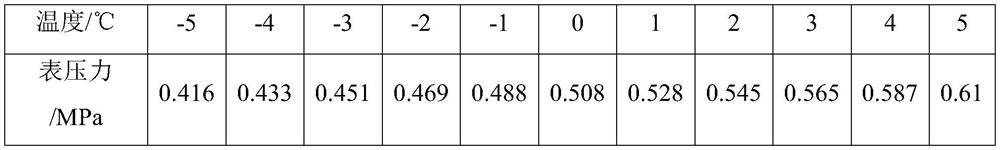

[0026] 2) Calculate the current evaporation temperature difference T according to the current return air temperature and low pressure in the cooling state K , the evaporation temperature difference is defined as the difference between the return air temperature and the evaporation temperature (converted from low pressure);

[0027] 3) Obtain the evaporation temperature T of the system pre-measured by the system according to the current return air temperature look-up table S , and calculate the difference T of the curren...

Embodiment 2

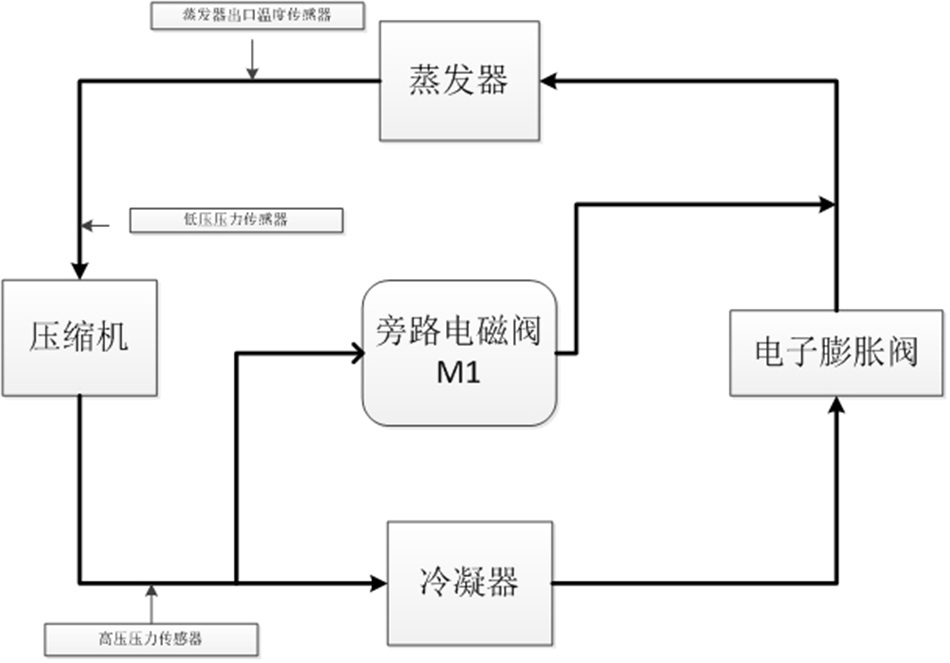

[0039] A refrigeration system with intelligent defrosting, such as figure 2 As shown, it includes an evaporator, a compressor, and a condenser. A circuit is formed by a pipeline, and the pipeline is filled with refrigerant. The low-pressure pressure section of the circuit is equipped with a low-pressure pressure sensor, that is, a low-pressure The pressure sensor is used to measure the pressure of the current low pressure. The high pressure section of the circuit is equipped with a high pressure sensor, that is, the pipeline between the compressor and the condenser is equipped with a high pressure sensor, which is used to measure the pressure of the current high pressure. ; There is an electronic expansion valve between the condenser and the evaporator, which is used for pressure regulation and throttling; there is also a branch circuit on the circuit, which is arranged in parallel with the condenser and the electronic expansion valve, and a bypass solenoid valve is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com