Bracket of self-deformation rubber-tyred rail construction vehicle

A tire-type, self-deformable technology, applied in the direction of track, track laying, track maintenance, etc., can solve problems such as inconvenience in construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

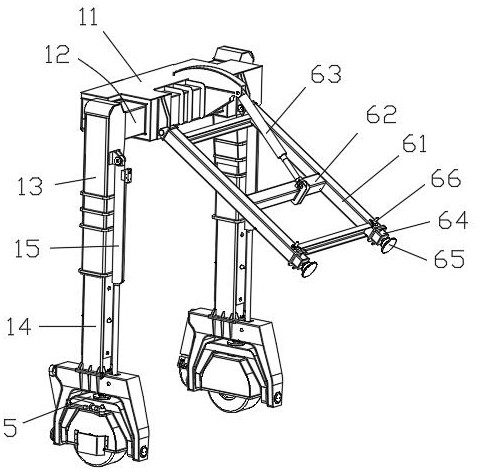

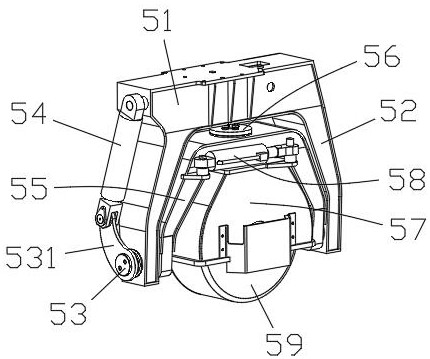

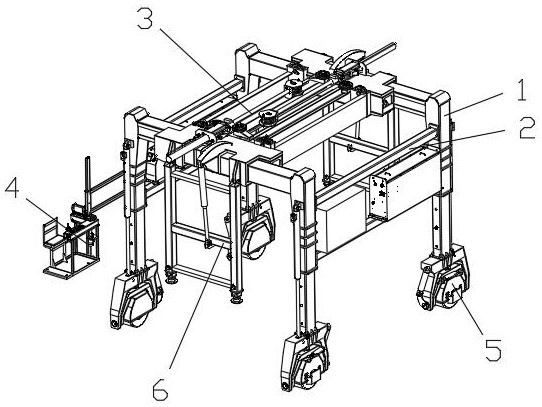

[0021]Such asFigure 1-6As shown, the bracket of the self-deformed tire rail construction vehicle provided by the present invention includes a fixing block 11, and both sides of the fixed block 11 have a slide, and slide the beam in each slide. 12. In the slide, the slide is installed with a first hydraulic cylinder for controlling the beam 12 in the chute, the beam 12 away from one end of the fixed block 11 fixed to the vertical arrangement of the sleeve 13, the sleeve 13 Slide the support shaft 14, and a second hydraulic cylinder 15 is mounted between the sleeve 13 and the support shaft 14, and the lower end of the support shaft 14 is equipped with a row wheel 5, and the travel wheel 5 includes a fixing frame 51, the fixing frame. The lower side is fixedly connected to the two stands, and each of the vertical plate 52 is provided with a first rotational hole, and the first rotating shaft 53 is rotated in the first rotating hole, one of which rotates one of them. One end of the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com